Abstract

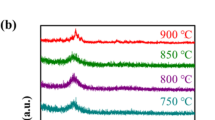

Barium strontium titanate (BST) (Ba1-x Sr x TiO3) thin films have been extensively used in many dielectric devices such as dynamic random access memories (DRAMs). To optimize its characteristics, a microstructural control is essential. In this paper, Ba0.6Sr0.4TiO3 thin film has been deposited on the SiO2/Si substrate by the pulsed laser deposition (PLD) technique at three different oxygen working pressures of 100, 220 and 350 mTorr. Then the deposited thin films at 100 mTorr oxygen pressure were annealed for 50 min in oxygen ambient at three different temperatures: 650, 720 and 800°C. The effect of oxygen working pressure during laser ablation and thermal treatment on the films was investigated by using X-ray diffraction (XRD), atomic force microscopy (AFM) and scanning electron microscopy (SEM) analysis methods. X-ray photoelectron spectroscopy analysis was used to determine the surface chemical composition of the samples. The results indicate that the deposited BST film at low working pressure (100 mTorr) in PLD chamber shows a lower surface roughness than other working pressures (220 and 350 mTorr). The as-deposited films show an amorphous structure and would turn into polycrystalline structure at annealing temperature above 650°C. Increase of temperature would cause the formation of cubic and perovskite phases, improvement in crystalline peaks and also result in the decomposition of BST at high temperature (above 800°C). In addition, rising of temperature leads to the increase in size of grains and clusters. Therefore more roughness was found at higher temperatures as a result of a more heterogeneous growth and less tensions.

Similar content being viewed by others

References

Wang Y Q, Liang W S, Petrov P K and Alford N M 2011 Mater. Charact. 62 294

Ahmad A, Goldthorpe I A and Khandani A K 2015 Appl. Phys. Lett. Rev. 2 011302

Remmel T, Gregory R and Baumert B 1999 International Centre for Diffraction Data

Kumar A, Manavalan S G, Gurumurthy V, Jeedigunta S and Weller T 2007 Mater. Sci. Eng. B 139 177

Padmini P, Taylor T R, Lefever M J, Nagra A S, York R A and Speck J S Appl. Phys. Lett. 75 3186

Saif A A and Poopalan P 2011 J. Mater. Sci. Technol. 27 802

Zhu H, Miao J, Noda M and Okuyama M 2004 Sens. Actuators A 110 371

Kocanda M, Mohiudin S F and Abdel-Motaleb L 2012 Cryst. Struct. Theory Appl. 1 17

Bäuerle D 2011 4th ed, Springer Publication, ISBN 978-3-642-17612-8

Horikawa T, Mikami N, Makita T, Tanimura J, Kataoka M, Kazunao S and Nunoshita M 1993 Jpn. J. Appl. Phys. 32 4130

Gao D, Xiao D, Bi J, Yu P, Yu G, Zhang W and Zhu J U 2003 Mater. Trans. 44 1320

Xing S, Song Z and Lin C 2002 Mater. Lett. 54 447

Jin H Z, Zhu J, Ehrhart P, Fitsilis F, Jia C L, Regnery S, Urban K and Waser R 2003 Thin Solid Films 429 282

Tang X G, Xiong H F, Jiang L L and Chan H L W 2005 J. Cryst. Growth 285 613

Xiaohong Z, Dongning Z, Wei P, Jianguo Z, Xiaowu Y, Jie L, Mingjian Z, Yingfei C, Haiyan T and Xiaoping X 2004 Mater. Lett. 58 3591

Saravanan K V and Raju K C J 2014 Mater. Res. Express 1 015706

Liao J X, Yang C R, Tian Z, Yang H G and Jin L 2006 J. Phys. D: Appl. Phys. 39 2473

Craciun V and Singh R K 2000 Appl. Phys. Lett. 76 14

Lee J H and Rhee S W 1999 J. Electrochem. Soc. 146 3783

Voigts F, Damjanovíc T, Borchardt G, Argirusis C and Friedrichs W M 2006 J. Nanomater. 63154 1

Joo J H, Seon J M, Jeon Y C, Oh K Y, Roh J S and Kim J J 1997 Appl. Phys. Lett. 70 3053

Tubchareon T, Soisuwan S, Ratanathammaphan S and Praserthdam P 2013 J. Lumin. 142 75

Tahmasebi N, Mahdavi S M and Irajizad A 2013 Appl. Surf. Sci. 273 261

Zhang X Y, Wang P, Xu F and Ong C K 2009 Solid-State Electron. 53 993

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

SAROUKHANI, Z., TAHMASEBI, N., MAHDAVI, S.M. et al. Effect of working pressure and annealing temperature on microstructure and surface chemical composition of barium strontium titanate films grown by pulsed laser deposition. Bull Mater Sci 38, 1645–1650 (2015). https://doi.org/10.1007/s12034-015-0982-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12034-015-0982-0