Abstract

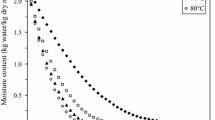

The aim of this research was to study the behaviour of the drying kinetics of pepino fruit (Solanum muricatum Ait.) at five temperatures (50, 60, 70, 80 and 90 °C). In addition, desorption isotherms were determined at 20, 40 and 60 °C over a water activity range from 0.10 to 0.90. The Guggenheim, Anderson and de Boer model was suitable to depict the desorption data. A monolayer moisture content from 0.10 to 0.14 g water g−1 d.m. was reported. The equations of Newton, Henderson–Pabis, Modified Page, Wang–Singh, Modified Henderson–Pabis, Logarithmic as well as standardised Weibull were tested for modelling drying kinetics. Besides, Fick’s second law model was used to calculate the water diffusion coefficient which increased with temperature from 2.55 to 7.29 × 10−10 m2 s−1, with estimated activation energy of 27.11 kJ mol−1. The goodness of fit of the models was evaluated using sum squared error and chi-square statistical tests. The comparison of the experimental moisture values with respect to the calculated values showed that the standardised Weibull model presented the best goodness of fit, showing that this equation is very accurate for simulating drying kinetics for further optimisation of drying times.

Similar content being viewed by others

Abbreviations

- a w :

-

Water activity (dimensionless)

- X we :

-

Equilibrium moisture content (g water g−1 d.m.)

- X wt :

-

Moisture content (g water g−1 d.m.)

- X wo :

-

Initial moisture content (g water g−1 d.m.)

- X m :

-

Monolayer moisture content (g water g−1 d.m.)

- C, K:

-

Parameters of GAB model

- D we :

-

Water diffusion coefficient (m2 s−1)

- L :

-

Half-thickness of the slab (m)

- k i :

-

Kinetic parameters (min−1)

- n i , c:

-

Empirical parameters (dimensionless)

- α :

-

Shape parameter (dimensionless) of the Weibull model

- β :

-

Scale parameter (min) of the Weibull model

- t :

-

Drying time (s, min)

- i :

-

Number of terms

- R :

-

Universal gas constant (8.314 J mol−1 K−1)

- T :

-

Absolute temperature (K)

- E a :

-

Activation energy (kJ mol−1)

- MRei :

-

Experimental moisture ratio (dimensionless)

- MRci :

-

calculated moisture ratio (dimensionless)

- z :

-

Number of constants of the model

- N :

-

Number of data values

- d.m.:

-

Dry matter

References

Association of Official Analytical Chemists (AOAC) (1990). Official method of analysis, Association of Official Analytical Chemists no. 934.06 (15th edition), Arlington, MA, Washington.

Abbasi, S. B., & Mowla, D. (2007). Drying behavior of fresh green beans in an inert medium fluidized bed. Journal of Food Processing and Preservation, 32(5), 697–718.

Akanbi, C. T., Adeyemi, R. S., & Ojo, A. (2006). Drying characteristics and sorption isotherm of tomato slices. Journal of Food Engineering, 73(2), 157–163.

Akpinar, E. K. (2006). Determination of suitable thin layer drying curve model for some vegetables and fruits. Journal of Food Engineering, 73(1), 75–84.

Akpinar, E. K., Bicer, Y., & Yildiz, C. (2003). Thin layer drying of red pepper. Journal of Food Engineering, 59(1), 99–104.

Altenhofen da Silva, M., Arévalo, R., & Guenter, T. (2005). Ascorbic acid thermal degradation during hot air drying of Camu-Camu (Myrciaria dubia [H.B.K.] McVaugh) slices at different air temperature. Drying Technology, 23, 2277–2287.

Arslan, N., & Toğrul, H. (2005). Moisture sorption isotherms for crushed chillies. Biosystems Engineering, 90(1), 47–61.

Azzouz, S., Guizani, A., Joma, W., & Belghith, A. (2002). Moisture diffusivity and drying kinetic equation of convective drying of grapes. Journal of Food Engineering, 55(4), 323–330.

Babalis, S. J., & Belessiotis, V. G. (2004). Influence of drying conditions on the drying constants and moisture diffusivity during the thin layer drying of figs. Journal of Food Engineering, 65(3), 449–458.

Bellagha, S., Sahli, A., & Farhat, A. (2008). Desorption isotherms and isosteric heat of three Tunisian date cultivars. Food and Bioprocess Technology, 1, 270–275.

Chen, C. (2002). Sorption isotherm of sweet potato slices. Biosystems Engineering, 83(1), 85–95.

Chua, K. J., Chou, M. N., Hawlader, A. S., Mujumdar, A. S., & Ho, J. C. (2002). Modelling the moisture and temperature distribution within an agricultural product undergoing time-varying drying schemes. Biosystems Engineering, 81(1), 99–111.

Corzo, O., Bracho, N., Pereira, A., & Vásquez, A. (2008). Weibull distribution for modeling air drying of coroba slices. LWT—Food Science and Technology, 41(10), 2023–2028.

Crank, J. (1975). The mathematics of diffusion (2nd edition). London: Oxford University Press.

Cunha, L. M., Oliveira, F. A. R., Aboim, A. P., & Frías, J. M. (2001). Stochastic approach to the modelling of water losses during osmotic dehydration and improved parameter estimation. International Journal of Food Science and Technology, 36, 253–262.

Diaz, L. (2006). Industrialización y aprovechamiento de productos y sub-productos derivados de materias primas agropecuarias de la región de Coquimbo (1st edition). Santiago: LOM ediciones Ltda.

Di Scala, K., & Crapiste, G. (2008). Drying kinetics and quality changes during drying of red pepper. LWT—Food Science and Technology, 41(5), 789–795.

Doymaz, I. (2008). Convective drying kinetics of strawberry. Chemical Engineering and Processing, 47(5), 914–919.

Doymaz, I., Tugrul, N., & Pala, M. (2006). Drying characteristics of dill and parsley leaves. Journal of Food Engineering, 77(3), 559–565.

Fahrettin, G., Medeni, M., & Ahmet, K. (1998). Sorption isotherms of Turkish delight. Journal of Food Processing and Preservation, 22, 345–357.

García-Pascual, P., Sanjuán, N., Melis, R., & Mulet, A. (2006). Morchella esculenta (morel) rehydration process modeling. Journal of Food Engineering, 72(4), 346–353.

Garcia-Pérez, J., Alves-Filho, O., Eikevik, T., Strommen, I., & Mulet, A. (2005). Effect of drying air temperature on heat pump fluidized bed drying of cód fish. Paris: Association Francaise de Sechage pou l’Industrie et l’Agriculture, AFSIA.

Giner, A. S. (2009). Influence of internal and external resistances to mass transfer on the constant drying rate period in high-moisture foods. Biosystems Engineering, 102, 90–94.

Giraldo-Zuniga, A., Arévalo-Pinedo, A., Rezende, J., Silva, C., & Monteiro, J. A. (2006). Drying kinetics for murici (Byrsonima crassifolia) fruit. Journal of Food Processing and Preservation, 30, 699–705.

Goula, A. M., Karapantsios, T. D., Achilias, D. S., & Adamopoulos, K. G. (2008). Water sorption isotherms and glass transition temperature of spray dried tomato pulp. Journal of Food Engineering, 85(1), 73–83.

Hii, C. L., Law, C. L., & Cloke, M. (2009). Modeling using a new thin layer drying model and product quality of cocoa. Journal of Food Engineering, 90(2), 191–198.

Huyskens-Keil, S., Prono-Widayat, H., Lüdders, P., & Schreiner, M. (2006). Postharvest quality of pepino (Solanum murcatum Ait) fruit in controlled atmosphere storage. Journal of Food Engineering, 77(3), 628–634.

Kaya, A., & Aydin, O. (2007). Experimental investigation of drying kinetics of cherry laurel. Journal of Food Processing Engineering, 31, 398–412.

Kaya, A., Aydin, O., & Demirtas, C. (2007). Drying kinetics of red delicious apple. Biosystems Engineering, 96(4), 517–524.

Kaymak-Ertekin, F., & Gedik, A. (2004). Sorption isotherms and isosteric heat of sorption for grapes, apricots, apples and potatoes. LWT—Food Science and Technology, 37(4), 429–438.

Lee, J. H., & Lee, M. J. (2008). Effect of drying method on the moisture sorption isotherms for Inonotus obliquus mushroom. LWT—Food Science and Technology, 41(8), 1478–1484.

Lemus, R., Pérez, M., Andrés, A., Roco, T., Tello, C., & Vega, A. (2007). Kinetic study dehydration and desorption isotherms of red alga Gracilaria. LWT—Food Science and Technology, 41(9), 1592–1599.

Marabi, A., Livings, S., Jacobsons, M., & Saguy, I. S. (2003). Normalized Weibull distribution for modeling rehydration of food particulates. European Food Research Technology, 217, 311–318.

Marfil, P. H. M., Santos, E. M., & Telis, V. R. N. (2008). Ascorbic acid degradation kinetics in tomatoes at different drying conditions. LWT—Food Science and Technology, 41(9), 1642–1647.

Martinez-Romero, D., Serrano, M., & Valero, D. (2003). Physiological changes in pepino (Solanum muricatum Ait) fruit stored at chilling and non-chilling temperatures. Postharvest Biology and Technology, 30, 117–186.

Midilli, A., & Kucuk, H. (2003). Mathematical modelling of thin layer drying of pistachio by using solar energy. Energy Conversion and Management, 44(7), 1111–1122.

Pangavhane, D. R., Sawhney, R. L., & Sarsavadia, P. N. (2000). Drying kinetic studies on single layer Thompson seedless grapes under controlled heated air conditions. Journal of Food Processing and Preservation, 24, 335–352.

Pardeshi IL & Chattopadhyay PK (2008). Hot air puffing kinetics for soy-fortified wheat-based ready-to-eat (RTE) snacks. Food and Bioprocess Technology, doi:10.1007/s11947-008-0100-z.

Sacilik, K., & Elicin, A. K. (2006). The thin layer drying characteristics of organic apple slices. Journal of Food Engineering, 73(3), 281–289.

Simal, S., Femenia, A., Garau, M., & Crosello, C. (2005). Use of exponential Page’s and diffusional models to simulate the drying kinetics of kiwi fruit. Journal of Food Engineering, 66(3), 323–328.

Spiess, W., & Wolf, W. (1983). The results of the COST 90 project on water activity. In R. Jowitt, et al. (Eds.), Physical properties of foods. London: Applied Science.

Toğrul, I. T., & Pehlivan, D. (2003). Modeling of drying kinetics of simple apricot. Journal of Food Engineering, 58(1), 23–32.

Vega, A., Uribe, E., Lemus, R., & Miranda, M. (2007). Hot-air drying characteristics of aloe vera (Aloe barbadensis Miller) and influence of temperature on kinetics parameters. LWT—Food Science and Technology, 40(10), 1698–1707.

Vega-Gálvez, A., Lemus-Mondaca, R., Bilbao-Sáinz, C., Yagnam, F., & Rojas, A. (2007). Mass transfer kinetics during convective drying of red pepper var.Hungarian (Capsicum annum L.): mathematical modeling and evaluations of kinetic parameters. Journal of Food Process Engineering, 31, 120–137.

Viswanathan, R., Jayas, D., & Hulasare, R. B. (2003). Sorption isotherms of tomato slices and onion shreds. Biosystems Engineering, 86(4), 465–472.

Acknowledgements

The authors thank the Research Office of Universidad de La Serena, Chile, for the support provided through Project DIULS No. 220-2-06 as well as the Research Fund of the Department of Food Engineering of Universidad Católica de Valparaiso, Chile.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Uribe, E., Vega-Gálvez, A., Di Scala, K. et al. Characteristics of Convective Drying of Pepino Fruit (Solanum muricatum Ait.): Application of Weibull Distribution. Food Bioprocess Technol 4, 1349–1356 (2011). https://doi.org/10.1007/s11947-009-0230-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-009-0230-y