Abstract

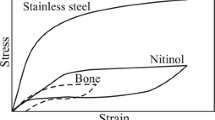

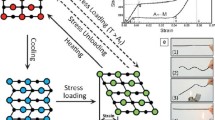

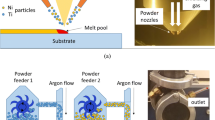

The purpose of this paper is to review the current processing and resultant properties of Nitinol for medical device applications. The melting and fabrication of Nitinol present a number of unique challenges because of the strong sensitivity of the alloy system to chemistry and processing. The first part of this paper will summarize the effect of alloy fabrication on key material properties, vacuum-melting techniques, hot working, and cold working. The effects of the final shape-setting heat treatments on transformation temperature and mechanical properties for medical devices will also be reviewed.

Similar content being viewed by others

References

D. Stöckel, Min. Invas. Ther. & Allied Technol., 9 (2000), pp. 81–88.

T.G. Frank, W. Xu, and A. Cuschieri, Proceedings of the International Conference on Shape Memory and Superelastic Technologies, ed. S.M. Russell and A.R. Pelton (Pacific Grove, CA: International Organization on SMST, 2001), pp. 549–560.

T. Duerig and M. Wholey, Min. Invas. Ther. & Allied Technol., 11 (2002), pp. 173–178.

D. Stöckel, C. Bonsignore, and S. Duda, Min. Invas. Ther. & Allied Technol., 11 (2002), pp. 137–147.

D. Stöckel, A.R. Pelton, and T. Duerig, Euro Rad. (to be published 2003).

W. Buehler and F.E. Wang, Ocean Eng., 1 (1968), pp. 105–120.

T.W. Duerig et al., eds., Engineering Aspects of Shape Memory Alloys (London: Butterworth-Heinemann Ltd., 1990).

H. Funakubo, ed., Shape Memory Alloys (New York: Gordon and Breach Science Publishers, 1987).

L.Mc. Schetky, “Shape Memory Alloys,” Scientific American, 241 (5) (1979), pp. 74–82.

J. Perkins, ed., Shape Memory Effects in Alloys (New York: Plenum Press, 1975).

T.W. Duerig and A.R. Pelton, “Ti-Ni Shape Memory Alloys,” Materials Properties Handbook: Titanium Alloys, ed. R. Boyer, G. Welsch, and E.W. Collings (Materials Park, OH: ASM International, 1994), pp. 1035–1048.

ASTM F 2004-00 Test Method for Transformation Temperature of Nickel-Titanium Alloys by Thermal Analysis (West Conshohocken, PA: ASTM, 2002).

C.M. Jackson, H.J. Wagner, and R.J. Wasilewski, NASA-SP 5110 (Washington, D.C.: DoE Technology Utilization Office, 1972).

ASTM F 2063-00 Standard Specification for Wrought Nickel-Titanium Shape Memory Alloys for Medical Devices and Surgical Implants (West Conshohocken, PA: ASTM, 2002).

S.M. Russell and D.E. Hodgson, Min. Invas. Ther. & Allied Technol., 9 (2000), pp. 61–65.

S.M. Russell, Proceedings of the International Conference on Shape Memory and Superelastic Technologies, ed. S.M. Russell and A.R. Pelton (Pacific Grove, CA: International Organization on SMST, 2001), pp. 1–10.

A.R. Pelton, J. DiCello, and S. Miyazaki, Min. Invas. Ther. & Allied Technol., 9 (2000), pp. 107–118.

A.R. Pelton, J. DiCello, and S. Miyazaki, Proceedings of the International Conference on Shape Memory and Superelastic Technologies, ed. S.M. Russell and A.R. Pelton (Pacific Grove, CA: International Organization on SMST, 2001), pp. 361–374.

T.W. Duerig and R. Zadno, Engineering Aspects of Shape Memory Alloys, ed. T.W. Duerig et al. (London: Butterworth-Heinemann Ltd., 1990), pp. 369–393.

S. Miyazaki, Engineering Aspects of Shape Memory Alloys, ed. T.W. Duerig et al. (London: Butterworth-Heinemann Ltd., 1990), pp. 394–413.

M. Nishida, C.M. Wayman, and T. Honma, Met. Trans. A, 17A (1986), pp. 1505–1515.

Author information

Authors and Affiliations

Additional information

For more information, contact A.R. Pelton, Nitinol Devices & Components, a Johnson & Johnson Company, 47533 Westinghouse Drive, Fremont, California 94539 USA; (510) 623-6996; fax (510) 623-6808; e-mail apelton@ndcus.jnj.com.

Rights and permissions

About this article

Cite this article

Pelton, A.R., Russell, S.M. & DiCello, J. The physical metallurgy of nitinol for medical applications. JOM 55, 33–37 (2003). https://doi.org/10.1007/s11837-003-0243-3

Issue Date:

DOI: https://doi.org/10.1007/s11837-003-0243-3