Abstract

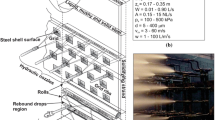

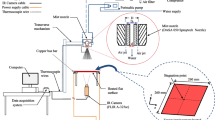

For the conditions of thin-slab continuous casting, air-mist secondary cooling occurs in the transition-boiling regime, possibly as a result of an enhanced intermittent contact of high- momentum water drops with the hot metallic surface. The dynamics of the intermittent contact or wetting/dewetting process should be primarily dependent on the drop size, drop impact-velocity and -angle and water-impact flux, which results from the nozzle design and the interaction of the drops with the conveying and entrained air stream. The aim of this article was to develop a model for predicting the last three parameters based on the design and operating characteristics of air-mist nozzles and on experimentally determined drop-size distributions. To do this, the Eulerian fluid-flow field of the air in three dimensions and steady state and the Lagrangian velocities and trajectories of water drops were computed by solving the turbulent Navier–Stokes equation for the air coupled to the motion equation for the water drops. In setting this model, it was particularly important to specify appropriately the air-velocity profile at the nozzle orifice, as well as, the water-flux distribution, and the velocities (magnitude and angle) and exit positions of drops with the different sizes generated, hence special attention was given to these aspects. The computed drop velocities, water-impact flux distributions, and air-mist impact-pressure fields compared well with detailed laboratory measurements carried out at ambient temperature. The results indicate that under practical nozzle-operating conditions, the impinging-droplet Weber numbers are high, over most of the water footprint, suggesting that the droplets should establish an intimate contact with the solid surface. However, the associated high mean-droplet fluxes hint that this contact may be obstructed by drop interference at the surface, which would undermine the heat-extraction effectiveness of the impinging mist. The model also points out that a large proportion of fine drops would be prevented by the air-flow pattern from reaching the surface. The numerical analysis of air-mist jets under conditions relevant to secondary cooling had not been addressed before, and it constitutes a first step in an effort to develop a model to describe the dynamic and thermal interaction of dense-drop media with hot metallic surfaces.

Similar content being viewed by others

Abbreviations

- A :

-

air flow rate at normal conditions (i.e., 0 °C, 101.3 kPa) (NL/s)

- A(x,y):

-

local area in impact plane centered around coordinates, x, y

- a, b, α, β, γ, γ o :

- C 1, C 2, C d :

-

constants in the turbulence model

- C D :

-

drag coefficient

- d d , d o :

-

drop diameter; diameter of deformed drops with cylindrical shape (m)

- f :

-

liquid fraction of the mist flow

- f μ , f 1, f 2 :

-

functions in turbulence model

- g :

-

acceleration due to gravity (m/s2)

- k :

-

turbulence kinetic energy (m2/s2)

- l x , l y :

-

half length and half width, respectively, of nozzle orifice (m)

- N A :

-

number of drops per unit area impacting onto a surface in a time interval Δt (drops/m2)

- n, N, \( \mathop N\limits^ \bullet \) :

-

droplet-number density in mist (drops/m3); number frequency; droplet-number flux (drops/m2 s)

- n p :

-

port number or number of ports

- p a , p zs :

-

air-nozzle pressure; pressure exerted by the mist on the impinging surface (kPa)

- P A , P :

-

local pressure exerted by the air of an air or mist jet impinging on a surface; pressure (kPa)

- E ϕP :

-

residual of the discretized equation for the flow variable ϕ (i.e., U i , k, ε) at node P

- Re d , Re t , Re z′ :

-

Reynolds number for drop phase; high turbulence Reynolds numbers

- S :

-

source term for momentum-transfer interaction between the drops and the air (m/s2)

- S A :

-

surface-area fraction covered by deformed drops in a time period (Δt)

- Δt, t :

-

time interval; time (s)

- u, u z,o , u z,t :

-

velocity of the discontinuous phase (drops); initial z-velocity component of drop in the mixing chamber; terminal velocity of drops and drop velocity at nozzle orifice (m/s)

- U :

-

velocity of the continuous phase (air) (m/s)

- v :

-

volume (m3)

- w, W :

-

water-impact density (L/m2 s); water-flow rate (L/s)

- We zs :

-

impinging-droplet Weber number

- x, y, z :

-

rectangular coordinates (m)

- z o , z mc , z s , z′ :

-

initial position of drops in mixing chamber; length of mixing chamber; setback distance; distance from solid surface (m)

- ε :

-

dissipation rate of turbulence kinetic energy (m2 s−3)

- ν, ν t , ν eff :

-

continuous-phase molecular, turbulent, and effective kinematic viscosities (m2 s−1)

- ρ, ρ d :

-

continuous-phase density; discontinuous-phase density (kg m−3)

- σ :

-

surface tension (N m−1)

- σ k , σ ε ,:

-

laminar and turbulent Schmidt numbers for k and ε

- \( \mathop \eta \limits^ \bullet \) :

-

number-flow rate of drops (s−1)

- τ d :

-

period between consecutive drops impinging on the same site (s)

- amb:

-

ambient conditions, P = 86 kPa, T = 25 °C

- cell:

-

discretization cell

- d :

-

drop with diameter (d)

- i, j :

-

indexes for coordinate directions

- k :

-

index for ports or trajectories

- x, y, z :

-

coordinate directions or indexes for vector components

- max:

-

maximum

- o :

-

orifice

- T :

-

total number

- o, n :

-

indexes to indicate output and input to control volume

References

J.K. Brimacombe, P.K. Agarawal, L.A. Baptista, S. Hibbins, and B. Prab-hakar: Proc. 3rd Steelmaking Conf., NOH-BOS Conf., Washington DC, Mar. 23–25, 1980, L.G. Kuhn, R.K. Azar, and G.S. Lucenti, eds., ISS-AIME, Warrendale, PA, 1980, vol. 63, pp. 235–52

J.J. Montes R., A.H. Castillejos E., F.A. Acosta G., M.A. Herrera G.: Can. Metall. Q., vol. 47, 2008, pp. 187–204

S.G. Hibbins, J.K. Brimacombe: ISS Trans., 1983, vol. 3, pp. 77–89

F.K. McGinnis, J.P. Holman: Int. J. Heat Mass Transfer, 1969, vol. 12, pp. 95–108

C.O. Pedersen: Int. J. Heat Mass Transfer, 1970, vol. 13, pp. 369–79

K. Araki, A. Moriyama: Trans. ISIJ, 1981, vol. 21, pp. 583–90

L.H.J. Wachters, N.A. Westerling: Chem. Eng. Sci., 1966, vol. 21, pp. 1047–56

K. Araki, S.-I. Yoshinobu, Y. Nakatani, and A. Moriyama: Trans. ISIJ., vol. 22, pp. 953–58

H. Xie, S. Koshizuka, Y. Oka: Int. J. Numer. Methods Fluids, 2004, vol. 45, pp. 1009–23.

K.J. Choi, S.C. Yao: Int. J. Heat Mass Transfer, 1987, vol. 30, pp. 311–18

S. Deb, S.C. Yao: Int. J. Heat Mass Transfer, 1989, vol. 32, pp. 2099–2112

N. Sozbir, Y.W. Chang, S.C. Yao: Trans. ASME, 2003, vol. 125, pp. 71–74

Y.A. Buyevich, V.N. Mankevich: Int. J. Heat Mass Transfer, 1995, vol. 38, pp. 731–44.

S.C. Yao, K.Y. Cai: Exp. Therm. Fluid Sci., 1988, vol. 1, pp. 363–71

N. Hatta, H. Fujimoto, R. Ishii, J.-I. Kokado: ISIJ Int., 1991, vol. 31, pp. 53–61

N. Hatta, H. Fujimoto, R. Ishii: ISIJ Int., 1991, vol. 31, pp. 342–49

R.J. Issa, S.C. Yao: J. Thermophys. Heat Transfer, 2005, vol. 19, pp. 441–47

M.S. Jenkins, S.R. Story, and R.H. David: Proc. 19th Australasian Chem. Eng. Conf., CHEMECA 91, Newcastle, New South Wales, Australia, Sept. 12–20, 1991, Institute of Chemical Engineers, North Melbourne

L. Bendig, M. Raudensky, and J. Horsky: 78th Steelmaking Conf. Proc., D.L. Creazzi, C.E. Slater, and K.A. Catanzarite, eds., Nashville, TN, ISS, Warrendale, PA, 1995, vol. 78, pp. 391–98

A.H. Castillejos E., F.A. Acosta G., M.A. García G., R. Santos P., and I. Torres: Design, Development and Testing of a New Secondary Cooling System for Increasing the Casting Velocity of Thin Slabs, Report for HYLSA, S.A. de C.V., DAP, Monterrey, N.L., Mexico, March 6, 2006

A.H. Castillejos E., F.A. Acosta G., M.A. Herrera, I. Hernández C., and E.P. Gutiérrez M.: ICS Proc. 2005, Charlotte, NC, AIST, Warrendale, PA, May 8–11, 2005, pp. 881–90

J.I. Minchaca M.: M.Sc. Thesis, CINVESTAV-Unidad Saltillo, Coah., Mexico, Oct. 2007

C.T. Crowe, M.P. Sharma, D.E. Stock: J. Fluids Eng., 1977, vol. 99, pp. 325–32

C.R. Yap: Ph.D. Dissertation, University of Manchester, Manchester, United Kingdom, 1987

B.E. Launder, D.B. Spalding: Comput. Math. Appl. Mech. Eng., 1974, vol. 3, pp. 269–89

S. Plat, B. Huang, A.S. Mujumdar, W.J. Douglas: Annu. Rev. Num. Fluid Mech. Heat Transfer, 1989, vol. 2, pp. 157–97

S.J. Wang, A.S. Mujumdar: Appl. Therm. Eng., 2005, vol. 25, pp. 31–44

I. Hernández C.: Ph.D. Progress Reports, CINVESTAV–Unidad Saltillo, Coah., Mexico, Feb. 2007, 2008

D.B. Spalding: PHOENICS Software, Version 3.6.1, CHAM Ltd., London, 2006

I.V. Roisman, B. Prunet-Foch, C. Tropea, M. Vignes-Adler: J. Colloid Interface Sci., 2002, vol. 256, pp. 396–410

S. Toda: Heat Transfer—Japanese Res., 1974, vol. 3, pp. 1–44.

Acknowledgments

The authors thank the National Council for Science and Technology of Mexico for the financial support received through Research Grant Nos. P47644 and 57836. Two of the authors (IHC and JIMM) also thank CONACYT for their Ph.D. and M.Sc. scholarships, respectively

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted on January 28, 2008.

Rights and permissions

About this article

Cite this article

HERNÁNDEZ C., I., ACOSTA G., F., CASTILLEJOS E., A. et al. The Fluid Dynamics of Secondary Cooling Air-Mist Jets. Metall Mater Trans B 39, 746–763 (2008). https://doi.org/10.1007/s11663-008-9179-x

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-008-9179-x