Abstract

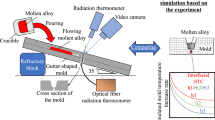

The heat transfer coefficient at the metal-mold interface (h MM) has been determined for the first time during the centrifugal casting of a Fe-C alloy tube using the inverse solution method. To apply this method, a centrifugal casting experiment was carried out to measure cooling curves within the tube wall under a mold rotation speed of 900 rpm, imposing a centrifugal force 106 times as large as the gravity force (106 G). As part of the solution method, a comprehensive heat transfer model of the centrifugal casting was also developed and coupled to an optimization algorithm. Finally, the evolution of h MM with time that gives the minimum squared error between measured and calculated cooling curves was obtained. The determined h MM is approximately 870 W m−2 K−1 immediately after melt pouring, decreasing to about 50 W m−2 K−1 when the average temperature of the tube is ~973 K (700 °C), after the end of solidification. Despite the existence of a centrifugal force that could enhance the metal-mold contact, these values are lower than those generally reported for static molds with or without an insulating coating at the mold inner surface. The implemented model shows that the heat loss by radiation is dominant over that by convection at the tube inner surface, causing the formation of a solidification front that meets another front coming from the outer surface of the tube.

Similar content being viewed by others

Abbreviations

- C E :

-

Eutectic composition (pct)

- C 0 :

-

Average alloy composition (pct)

- c p :

-

Specific heat (J kg−1 K−1)

- C SE :

-

Composition of the solid in equilibrium with the liquid at T E (pct)

- C S0 :

-

Composition of the solid in equilibrium with the liquid at T L (pct)

- D s :

-

Diffusion coefficient of carbon in austenite (m2 s−1)

- F ji :

-

View factor between surface patches j and i (−)

- h C :

-

Convection component of h RC (W m−2 K−1)

- h i :

-

i component of h MM (W m−2 K−1)

- h j :

-

mean heat transfer coefficient between rotating disk and fluid for j = 3c, 4c, 3ca (W m−2 K−1)

- h ic :

-

Convection heat transfer coefficient between surface patch i and air within tube cavity (W m−2 K−1)

- h MM :

-

Heat transfer coefficient at the metal-mold interface (W m−2 K−1)

- h 0 :

-

Constant of power-law model (W m−2 K−1)

- h RC :

-

Heat transfer coefficient at the inner surface of tube (W m−2 K−1)

- h R :

-

Radiation component of h RC (W m−2 K−1)

- h 3ca :

-

Convection heat transfer coefficient between front lid and environment (W m−2 K−1)

- h 4ca :

-

Convection heat transfer coefficient between backside of mold and cooling water (W m−2 K−1)

- J i :

-

Radiosity of surface patch i (W m−2)

- k * :

-

Corrected solute partition coefficient (−)

- l ic :

-

Thickness of the coating on surface patch i (m)

- l 3m :

-

Thickness of the front lid of mold (m)

- l 4m :

-

Thickness of backside of mold (m)

- L :

-

Length of cast tube (m)

- n :

-

Constant of power-law model (−)

- N :

-

Number of h i components of h MM

- Nu c :

-

Nusselt number at the surface of a rotating disk (R i h j/κ a)

- Nu i :

-

Nusselt number at the inner surface of tube (2R i h C/κ a )

- r :

-

Radial coordinate (m)

- R i :

-

Inner radius of cast tube (m)

- R e :

-

Outer radius of cast tube (m)

- Re c :

-

Reynolds number for a rotating disk (R 2i w/v a)

- Re r :

-

Rotational Reynolds number at the inner surface of tube (2R 2i w/v a)

- t :

-

Time (s)

- t f :

-

Local solidification time (s)

- t i :

-

Time of index i to define components of h MM (s)

- T :

-

Calculated temperature (K)

- T a :

-

Temperature of air outside the mold or of cooling water (K)

- T c :

-

Temperature of air inside the tube cavity (K)

- T E :

-

Eutectic temperature (K)

- T *f :

-

Corrected temperature of the pure metal (K)

- T i :

-

Initial temperature of the molten metal (K)

- T i :

-

Temperature of surface patch i (K)

- T L :

-

Liquidus temperature of the alloy (K)

- T m :

-

Temperature measured in the mold (K)

- T M :

-

Temperature measured by thermocouple (K)

- T Re :

-

Temperature of outer surface of tube (K)

- T Ri :

-

Temperature of inner surface of tube, also surface patch (1) (K)

- w :

-

Angular velocity of mold (rad s−1)

- α :

-

Fourier number (4D s t f/λ 2)

- ΔC :

-

Concentration factor

- ΔH e :

-

Latent heat of eutectic solidification (J kg−1)

- ΔH f :

-

Latent heat of austenite solidification (J kg−1)

- ɛ e :

-

Volume fraction of eutectic (−)

- ɛ i :

-

Emissivity of surface patch i (−)

- ɛ s :

-

Volume fraction of austenite (−)

- κ :

-

Average thermal conductivity (W m−1 K−1)

- κ a :

-

Thermal conductivity of air at the film temperature (W m−1 K−1)

- κ ic :

-

Thermal conductivity of the coating on surface patch i ( W m−1 K−1)

- κ im :

-

Thermal conductivity of mold material (W m−1 K−1)

- κ l :

-

Thermal conductivity of liquid melt (W m−1 K−1)

- κ s :

-

Thermal conductivity of austenite (W m−1 K−1)

- λ :

-

Secondary dendrite arm spacing (m)

- v a :

-

Kinematic viscosity of air at the film temperature (m2 s−1)

- ρ :

-

Density (kg m−3)

- σ :

-

Stefan–Boltzmann constant (W m−2 K−4)

- τ :

-

Constant of power-law model (s)

References

A. Royer and S. Vasseur: in ASM Handbook—Casting, D.M. Stefanescu, ed., ASM International, Metals Park, OH, 1998, pp. 296–307.

P. R. Beeley: Foundry Technology, Butterworth Heinemann, Oxford, 2001, pp. 622-645.

Y. Ebisu: Trans. AFS, 1977, vol. 85, pp. 643-59.

B. J. Yang, W. T. Liu and J. Y. Su: Trans. AFS, 1994, vol. 102, pp. 763-67.

G. Martinez, M. Garnier and F. Durand: Solidification Processing 1987, Proceedings of the Third International Conference, The Institute of Metals, London, 1988, pp. 357–60.

J. W. Gao and C. Y. Wang: Mat. Sci. Eng. A, 2000, vol. 292, pp. 207-15.

C. G. Kang, P. K. Rohatgi, C. S. Narendranath and G. S. Cole: ISIJ Int., 1994, vol. 34, pp. 247-54.

C. G. Kang and P. K. Rohatgi: Metall. Mater. Trans. B, 1996, vol. 27, pp. 277-85.

S. R. Chang, J. M. Kim and C. P. Hong: ISIJ Int., 2001, vol. 41, pp. 738-47.

P. S. S. Raju and S. P. Mehrotra: Mater. Trans. JIM, 2000, vol. 41, pp. 1626-35.

L. Drenchev, J. Sobczak, S. Malinov and W. Sha: Model. Simul. Mater. Sci. Eng., 2003, vol. 11, pp. 635-49.

L. Nastac, J.J. Valencia, J. Xu and H. Dong: Materials Processing in the Computer Age, V.R. Voller and H. Henein eds., The Minerals, Metals, and Materials Society, Materials Park, OH, 2000, pp. 1–18.

E. Panda, S. P. Mehrotra and D. Mazumdar: Metall. Mater. Trans. A, 2006, vol. 37, pp. 1675-87.

Z. Xu, N. Song, R. V. Tol, Y. Luan and D. Li: IOP Conference Series: Materials Science and Engineering, 2012, vol. 33, pp. 012030.

N. J. Humphreys, D. McBride, D. M. Shevchenko, T. N. Croft, P. Withey, N. R. Green and M. Cross: Applied Mathematical Modelling, 2013, vol. 37, pp. 7633-43.

R. Heringer, M. Boccalini, Jr, M.A. Martorano, and C. Serantoni: ASME Summer Heat Transfer Conference - HT2008, ASME, New York, 2008, vol. 2008, pp. 693–94.

M. A. Martorano and J. D. T. Capocchi: Int. J. Heat Mass Transf., 2000, vol. 43, pp. 2541-52.

M. Rappaz: Int. Mater. Rev., 1989, vol. 34, pp. 93-123.

H. Baker: in ASM Handbook—Alloy Phase Diagrams, H. Baker, ed., American Society for Metals, Metals Park, OH, 1992, pp. 2.110–2.10.

S. Seghir-Ouali, D. Saury, S. Harmand, O. Phillipart and D. Laloy: Int. J. Therm. Sci., 2006, vol. 45, pp. 1166-78.

C. A. Santos, J. M. V. Quaresma and A. Garcia: J. Alloy Compd., 2001, vol. 319, pp. 174-86.

W. Kurz and D. J. Fisher: Fundamentals of Solidification, Trans Tech Publications, Aedermannsdorf, 1989, pp. 130-135.

F. P. Incropera and D. P. DeWitt: Fundamentals of heat and mass transfer, Wiley, New York, 1996, pp. 811-847.

M. F. Modest: Radiative Heat Transfer, Academic, San Diego, CA, 2003, pp. 762-773.

C. J. Smithells, E. A. Brandes and G. B. Brook: Smithells metals reference book, Butterworth-Heinemann, Oxford, 1992, pp. 14.1 - 14.5.

D. D. Goettsch and J. A. Dantzig: Metall. Mater. Trans. A, 1994, vol. 25, pp. 1063-79.

U. Ekpoom and R. W. Heine: Trans. AFS, 1981, vol. 89, pp.27–38.

R. D. Pehlke, A. Jeyarajan and H. Wada: Summary of Thermal Properties For Casting Alloys and Mold Materials, University of Michigan, Ann Arbor, 1982, pp. 53-60.

N. Koker, G. Steinle-Neumann and V. Vlcek: Proc. Natl. Acad. Sci., 2012, vol. 109, pp. 4070-73.

Y. S. Touloukian: Thermophysical properties of high temperature solid materials, Macmillan, New York,, 1967, pp. 1344-1352.

K. Ho and R. D. Pehlke: Trans. AFS, 1984, vol. 92, pp. 587-98.

K. H. Spitzer: Int. J. Heat Mass Transf., 1991, vol. 34, pp. 1969-74.

F. Lau, W. B. Lee, S. M. Xiong and B. C. Liu: J Mat. Proc. Tech., 1998, vol. 79, pp. 25-29.

L. J. D. Sully: Trans. AFS, 1976, vol. 84, pp. 735–44.

F. Chiesa: Trans. AFS, 1990, vol. 98, pp. 193-200.

C. P. Hallam and W. D. Griffiths: Metall. Mater. Trans. B, 2004, vol. 35, pp. 721-33.

S. Harmand, J. Pellé, S. Poncet and I. V. Shevchuk: Int. J. Therm. Sci., 2013, vol. 67, pp. 1-30.

Acknowledgments

The authors thank Conselho Nacional de Desenvolvimento Científico e Tecnológico (CNPq) for the financial support (grant 310923/2011-5) and CAPES (Coordenação de Aperfeiçoamento de Pessoal de Nível Superior) for the scholarship to S. Vacca. They also thank the Key Reader for the comprehensive list of suggestions and comments.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted July 12, 2014.

Appendix

Appendix

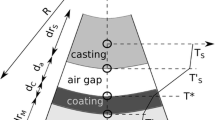

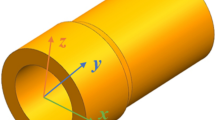

The radiation component of the heat transfer coefficient, h R, is required to calculate h RC and the total heat flux at the inner surface of the tube, defined by Eq. [7]. To construct a radiation model, the internal surface that forms the complete tube cavity was subdivided into 5 surface patches (Figure 1b): (1) differential surface element on the inner surface of the tube in the middle of its length; (2) complete inner surface; (3) front lid; (4) backside of the mold; and (5) opening in the front lid. The boundary at which Eq. [7] is applied coincides with surface patch (1) and the net radiation heat flux leaving this patch is exactly the radiation part of the total flux calculated by Eq. [7].

Each of the 5 patches was assumed to have uniform radiosity and uniform temperature, which vary from patch to patch. Surface patch (5), the lid opening, was assumed black and patches (1) to (4), opaque, diffuse, and gray. Patches (3) and (4) are actually the surfaces of the coatings on the front lid and back of the mold, respectively, and they exchange heat by radiation and convection due to the air flow within the cavity. The heat conducted through the coatings is also conducted through the walls of the front lid and back of mold and, eventually, transferred to the environment (front lid) and to the cooling water (back of mold). These heat transfer steps are included in the model using thermal resistances. Considering these assumptions, the following system of equations can be written[23]

The view factor between surface patches j and i, denoted as \( F_{ji} \), is calculated as explained by Modest.[24] Note that the temperature of surface patch (5) is the environment temperature, T a, and the temperature of patches (1) and (2) are equal to T Ri, obtained as part of the solution of Eq. [1], i.e., T at r = R i.

The convective heat transfer coefficients \( h_{{ 3 {\text{c}}}} \), \( h_{{ 4 {\text{c}}}} \), and \( h_{{ 3 {\text{ca}}}} \) were calculated using the following relation developed for the heat exchanged between a rotating disk and the surrounding fluid[37]

The heat transfer between the external surface of the mold back and the cooling water of the water jacket was approximated by the heat transfer between a static surface and an impinging jet,[23] enabling the calculation of \( h_{{ 4 {\text{ca}}}} \). In this calculation, the diameter of the water inlet was 5 cm, the distance between inlet exit and backside of mold was 10 cm, and the average velocity at the inlet was 3 ms−1.

The system of Eqs. [10] through [15] was solved by the iterative Gauss–Seidel method for six unknowns, namely \( J_{1} ,\;J_{2} ,\;J_{3} ,\;J_{4} ,\;T_{3} \), and \( T_{4} \), from which \( J_{1} \) is the necessary variable to finally calculated \( h_{\text{R}} \) as follows

The temperature at surface patch (1), \( T_{\text{Ri}} \), and the temperatures of the air in the environment, T a, and in the cavity, \( T_{\text{c}} \), should be given to enable a unique solution of the equation system, i.e., \( h_{\text{R}} = h_{\text{R}} \left( {T_{\text{Ri}} ,T_{\text{a}} ,T_{\text{c}} } \right) \). In the present work, T a = 25 °C and, since the temperature of the air in the internal cavity, T c, is unknown, the approximation \( T_{\text{c}} = \left( {T_{\text{Ri}} + T_{\text{a}} } \right)/2 \) was considered. A few tests with the model revealed that changes in T c in the range from T Ri to T a caused negligible variation in h R. Therefore, if T Ri is given, h R can be obtained, i.e., \( h_{\text{R}} = h_{\text{R}} \left( {T_{\text{Ri}} } \right) \). For the specific conditions of the present simulations, the complete radiation model was solved and this function was approximated by a polynomial of degree 2.

Rights and permissions

About this article

Cite this article

Vacca, S., Martorano, M.A., Heringer, R. et al. Determination of the Heat Transfer Coefficient at the Metal-Mold Interface During Centrifugal Casting. Metall Mater Trans A 46, 2238–2248 (2015). https://doi.org/10.1007/s11661-015-2770-2

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-015-2770-2