Abstract

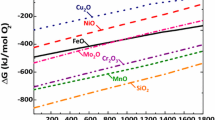

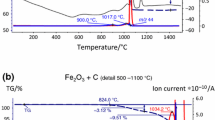

Oxygen-sensitive alloying elements such as Mn, Si, and Cr have a high potential for improving the properties of low alloyed sintered steels while reducing the alloying cost. However, it is necessary to find a way for avoiding, or at least minimizing, the oxidation of these elements especially during the early stages of the sintering cycle. In this study Mn, Si, and Cr were introduced in the form of a master alloy powder designed to be mixed with the iron base powder and provide the final composition of the steel during the sintering process. The reduction/oxidation phenomena taking place during the heating stage were studied by thermogravimetry, dilatometry, and mass spectroscopy, using either reducing (H2) or inert (Ar) atmospheres. The results show how the difference in chemical activity between base iron powder and master alloy causes the so called “internal-getter” effect, by which the reduction of less stable iron oxides leads to oxidation of the elements with higher affinity for oxygen. This effect can be somehow minimized when sintering in H2, since the iron oxides are reduced at lower temperatures at which the reactivity of the elements in the master alloy is lower. However, H2 concentration in the processing atmosphere needs to be carefully adapted to the specific composition of the materials being processed in order to minimize decarburization by methane formation during sintering.

Similar content being viewed by others

References

L. Albano-Müller, F. Thümmler and G. Zapf, Powder Metall. 1973, vol. 16, pp. 236-256.

G. Zapf and K. Dalal, Modern Developments in Powder Metallurgy 10, 1977, pp. 129-152.

H. Danninger and C. Gierl, Science of Sintering 2008, vol. 40, pp. 33-46.

M Jaliliziyaean, C. Gierl and H. Danninger, Advances in Powder Metallurgy & Particulate Materials 2008, vol. 5, pp. 72-78.

H. Danninger, M. Jaliliziyaeian, C. Gierl and S. Bengtsson, Materials Science Forum 2011, vol. 672, p. 4.

E. Hryha, C. Gierl, L. Nyborg, H. Danninger and E. Dudrova, Applied Surface Science 2010, vol. 256, pp. 3946-3961.

S. Banerjee, G. Schlieper, F. Thümmler and G. Zapf, Progress in Powder Metallurgy 1980, vol. 13, pp. 143-157.

G. Schlieper and F. Thummler: Powder Metall. Int. 1979, pp. 172, 174–76.

P. Jones and R. Lawcock: Stackpole Limited, US, 1997.

P. Jones and R. Lawcock: Stackpole Limited, US, 1999.

F. Castro, M. Sarasola, F. Baumgaertner, M. Dougan, S. Mitchell, K. Lipp, H.J. Bender, C. Coffin, and J. Dunkley: EuroPM2005, EPMA, ed. EPMA, Pragha, 2005.

P. Beiss, Advances in Powder Metallurgy & Particulate Material 2006, vol. 1, pp. 12-20.

S. Sainz, V. Martinez, M. Dougan, F. Baumgaertner, and F. Castro, Adv. Powder Metall. Part. Mater., 2006, 7:pp. 95-108.

A. Šalak and M. Selecká: Manganese in Powder Metallurgy Steels. Cambridge International Science, Cambridge, 2012.

A. N. Klein, R. Oberacker and F. Thummler, Powder Metallurgy International 1985, vol. 17, pp. 13-16.

A. N. Klein, R. Oberacker and F. Thummler, Powder Metallurgy International 1985, vol. 17, pp. 71-74.

A. N. Klein, R. Oberacker and F. Thummler, Modern Developments in Powder Metallurgy 1985, vol. 16, pp. 141-152.

F. Thummler, A. Klein, and R. Oberacker: Kernforschungszent Karlsruhe, 1983.

F. Thummler, A. Klein, and R. Oberacker: Kernforschungszent Karlsruhe, 1990.

R. Oro, M. Campos, J. M. Torralba and C. Capdevila, Powder Metall. 2012, vol. 55, pp. 294-301.

M.C. Abraham and A. Ghosh: Symposium on Science and Technology of Sponge Iron and Its Conversion to Steel, CSIR—National Metallurgical Laboratory, Jamshedpur, 1973, pp 106–16.

D.M. dos Santos and M.B. Mourao: Scandinavian Journal of Metallurgy 2004, vol. 33, pp. 229-235.

H. Danninger, G. Frauendienst, K. D. Streb and R. Ratzi, Mater. Chem. Phys. 2001, vol. 67, pp. 72-77.

H. Danninger and C. Gierl, Mater. Chem. Phys. 2001, vol. 67, pp. 49-55.

Mohammad Momeni, Christian Gierl and Herbert Danninger, Mater. Chem. Phys. 2011, vol. 129, pp. 209-216.

H. Danninger, C. Gierl, S. Kremel, G. Leitner, K. Jaenicke-Roessler and Y. Yu, Powder Metallurgy Progress 2002, vol. 2, pp. 125-140.

H. Danninger, C. Gierl, G. Leitner and K. Jaenicke-Roessler, P/M Science & Technology Briefs 2004, vol. 6, pp. 10-14.

C. Gierl, M. Jaliliziyaean, H. Danninger, and S. Berngtsson: Euro PM2009, EPMA, ed., EPMA: Copenhague, 2009, pp 305–10.

A. P. Long, S. L. Li, H. Wang and H. Z. Chen, Applied Surface Science 2014, vol. 295, pp. 180-188.

R. Oro, M. Campos, E. Hryha, J. M. Torralba and L. Nyborg, Materials Characterization 2013, vol. 86, pp. 80-91.

D. Chasoglou, E. Hryha and L. Nyborg, Mater. Chem. Phys. 2013, vol. 138, pp. 405-415.

E. Hryha, E. Dudrova and L. Nyborg, Journal of Materials Processing Technology 2012, vol. 212, pp. 977-987.

H. Danninger, M Jaliliziyaean, C. Gierl, E. Hryha, and S. Bengtsson: World PM2010, EPMA, ed., EPMA, Florence, Italy, 2010, pp. 3–10.

J.E. Japka, Journal of Metals 1988, vol. 40, pp. 18-21.

E. Hryha and E. Dudrova, Prog. Powder Metall., Pts 1-2 2007, vol. 534-536, pp. 761-764.

E. Hryha, E. Dudrova and L. Nyborg, Metall. Mater. Trans. A 2010, vol. 41A, pp. 2880-2897.

B. Lindsley and W.B. James, Advances in Powder Metallurgy & Particulate Material 2010, vol. 10, pp. 36-49.

K. Stölzel: Technik-Wörterbuch Metallurgie und Gießereitechnik: russ., dt., Verlag Technik, 1986.

G. Jangg, R. Kieffer, and P. Ettmayer: Sondermetalle, Wien-New York, 1971.

Acknowledgments

The authors wish to thank Höganäs AB Sweden for the financial support provided through the Höganäs Chair IV, as well as all the members of the project for their very valuable scientific support.

Author information

Authors and Affiliations

Corresponding author

Additional information

From 12th January 2015, Raquel de Oro Calderon will be at Vienna University of Technology.

Manuscript submitted March 24, 2014.

Rights and permissions

About this article

Cite this article

Oro, R., Campos, M., Gierl-Mayer, C. et al. New Alloying Systems for Sintered Steels: Critical Aspects of Sintering Behavior. Metall Mater Trans A 46, 1349–1359 (2015). https://doi.org/10.1007/s11661-014-2707-1

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-014-2707-1