Abstract

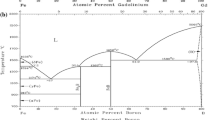

The liquidus projection of the Fe-rich corner of the B-Fe-U phase diagram is proposed based on powder X-ray diffraction measurements, differential thermal analysis, and scanning electron microscopy observations complemented by energy dispersive X-ray spectroscopy. The present work demonstrates the existence of 10 ternary reactions together with 18 monovariant lines and establishes their location and approximate temperatures. The ternary compounds existing in this region of the B-Fe-U ternary phase diagram, UFe3B2, UFe4B, and U2Fe21B6, were confirmed to form by ternary peritectic reactions, yet UFe4B and U2Fe21B6 have minute primary crystallization fields, indicating a more challenging preparation of single crystals for these compounds when compared with UFe3B2.

Similar content being viewed by others

References

V. Sechovsky and L. Havela: Magnetism of Ternary Intermetallic Compounds of Uranium, Prague, Czech Republic, vol. 11, chap. 1, 1998.

H. Noël, A.P. Gonçalves: Intermetallics, 2001, vol. 9, pp. 473.

I.P. Valyovka and Yu.B. Kuzma: Dop. Akad. Nauk Ukr. RSR, A: Fiz.-Tekhn. Mat. Nauki, 1975, p. 652.

I.P. Valyovka and Yu.B. Kuzma: Dop. Akad. Nauk Ukr. RSR, A: Fiz.-Tekhn. Mat. Nauki, 1974, p. 1029.

M. Dias, P.A. Carvalho, O. Sologub, O. Tougait, H. Noël, C. Godart, E. Leroy, and A.P. Gonçalves: Intermetallics, 2007, vol. 15, p. 413.

M. Dias, P.A. Carvalho, O. Sologub, L.C.J. Pereira, I.C. Santos, and A.P. Gonçalves: J. Alloy. Compd., 2009, vol. 492 (1–2), pp. L13–L15.

M. Dias, P.A. Carvalho, M. Bohn, O. Tougait, H. Noël, and A.P. Gonçalves: Metall. Mater. Trans., 2012. DOI: 10.1007/s11661-012-1369-0.

M. Dias, P.A. Carvalho, A.P. Dias, M. Bohn, N. Franco, O. Tougait, H. Noël, and A.P. Gonçalves: J. Phase Equilibria. Diffus., 2010, vol. 31 (2), p. 104.

W. Kurz, D.J. Fisher, “Fundamentals of solidification”, 3rd edition, Trans Tech Publications, Enfield, NH, 1992.

M.E. Glicksman, L.M. Mizenko, M.E. Rettenmayer, S.P. Marsh (1994) Mater. Sci. Eng. A, 178(1–2):137–46.

L. M. Colucci-Mizenko, M. E. Glicksman, R. N. Smith (1994) J Met 46(1):51-55.

F.N. Rhines: Phase Diagrams in Metallurgy: Their Development and Application, McGraw-Hill, New York, 1956.

A. Prince (1966) Alloy Phase Equilibria. Elsevier Pub. Co., Amsterdam.

T.B. Massalski, H. Okamoto, P.R. Subramanian, and L. Kacprzak, eds.: Binary Alloy Phase Diagrams, 2nd edn., ASM International, Metals Park, OH, 1990.

H. Okamoto: in Binary Alloy Phase Diagrams Updating Service, H. Okamoto, ed., ASM International, Metals Park, OH, 1991.

G. Nozle, W. Kraus, Powder Cell for Windows, Version 2.2, Federal Institute for Materials Research and Testing, Berlin, 1999.

C. Merlet (1994) Mikrochim Acta 114115:363–76.

Acknowledgments

This work was partially supported by FCT, Portugal, under the Contract No. PTDC/QUI/65369/2006, and by the international project PICS SCR-ITN 2011-2013.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted August 21, 2012.

Appendix

Appendix

1.1 Solidification Paths

Figure 10 shows the solidification path for 38B:52Fe:10U, 33B:50Fe:17U (UFe3B2 stoichiometry), 17B:73Fe:10U, 17B:66Fe:17U (UFe4B stoichiometry), and 9B:87Fe:4U alloys. In agreement with the liquidus surface proposed, the solidification path followed by the 38B:52Fe:10U alloy presented the following solidification sequence: L → UFeB4 → UFe3B2 → Fe2B → γ-Fe + UFe4B → γ-Fe + UFe4B + UFe2 (Figure 4(e)). The primary solidification of UFeB4 indicates that the alloy is situated in the crystallization field of this compound. According to the transition temperatures (Figure 7(a)), formation of UFe3B2 (below l15) occurred at 1503 K (1230 °C), formation of Fe2B (along and below l19) occurred at 1453 K (1180 °C), and solidification of γ-Fe + UFe4B mixture (along l22) occurred at 1303 K (1030 °C). The fact that l15 converges to U5 and l19 diverges from U5 implies that this ternary reaction occurs at 1453 K (1180 °C) < T < 1503 K (1230 °C). Moreover, since l15 operated at a temperature near 1503 K (1230 °C) (UFe3B2 formation) and is diverging from P3, it implies that P3 occurs at T > 1503 K (1230 °C) (Figure 10).

The microstructure of the 33B:50Fe:17U (UFe3B2 stoichiometry) alloy presents the following solidification sequence: L → UFeB4 → UFe3B2 → UFe4B + UFe2 → γ-Fe + UFe4B + UFe2 (Figure 4(f)). Solidification started with UFeB4, indicating that the alloy is situated inside the primary crystallization field of this compound. According to the transition temperatures (Figure 7(b)), the solidification of UFeB4 occurred at 1538 K (1265 °C) (above l15); the solidification of UFe3B2 (below l15) occurred at 1481 K (1208 °C). The solidification ended in the γ-Fe + UFe4B + UFe2 ternary eutectic, which occurs at 1263 K (990 °C). The fact that l15 diverges from P3 and converges to U5 implies that P3 occurs at T > 1538 K (1265 °C) and U5 occurs at T < 1538 K (1265 °C). Since l1 is diverging from P1[7] and converging to U3, the latter reaction must occur at T < 1933 K (1660 °C). Additionally, since l17 is diverging from the binary phase diagram[14,15] where it operates at 1662 K (1389 °C) and is converging to U4, the latter reaction must occur at T < 1662 K (1389 °C).

In agreement with the liquidus surface proposed, the solidification path followed by the 17B:73Fe:10U alloy presented the following solidification sequence: L → Fe2B → UFe3B2 → UFe2 + UFe4B → γ-Fe + UFe4B → γ-Fe + UFe2 + UFe4B (Figure 5(a)). Therefore, according to the DTA results, solidification started at 1468 K (1195 °C) with the formation of Fe2B and this indicates that the alloy is situated inside the primary crystallization field of this compound. Solidification of UFe3B2 (along or below l19) occurred at 1443 K (1170 °C), solidification of the UFe2 + UFe4B eutectic mixture (along l22) occurred at 1323 K (1050 °C), and solidification of γ-Fe + UFe4B (along l27) occurred at 1303 K (1030 °C). The fact that U2Fe21B6 phase is not present in the microstructure suggests that nucleation of this phase was hindered by kinetic reasons. The fact that l27 diverges from U8 enables the inference that this ternary reaction occurs at T > 1303 K (1030 °C). Since l19 converges to P4, this ternary reaction occurs at T < 1443 K (1170 °C).

The microstructure of the 17B:66Fe:17U (UFe4B stoichiometry) alloy evidences the following solidification sequence: L → UFe3B2 → UFe4B → UFe2 → UFe4B + UFe2 → γ-Fe + UFe2 + UFe4B (Figure 5(b)). Therefore, solidification initiated at 1373 K (1100 °C) with the formation of UFe3B2, indicating that the alloy is situated inside the primary crystallization field of this compound. The solidification of UFe4B (below l20) together with the solidification of the UFe2 + UFe4B eutectic mixture (along l22) occurred at 1293 K (1020 °C). The solidification ended in E3 with the γ-Fe + UFe2 + UFe4B ternary eutectic mixture at 1253 K (980 °C). Since l20 is converging to, and l22 is diverging from, U6, this ternary reaction occurs in the 1293 K (1020 °C) < T < 1373 K (1100 °C) temperature range. Consequently the lower temperature P5 occurs at T < 1373 K (1100 °C).

The microstructure of the 9B:87Fe:4U alloy presents the following solidification sequence: L → γ-Fe → U2Fe21B6 → γ-Fe + UFe4B → γ-Fe + UFe2 + UFe4B (Figure 5(e)). The primary solidification of γ-Fe occurred at 1438 K (1165 °C), the solidification of γ-Fe and U2Fe21B6 (along l26) occurred at 1323 K (1050 °C), and solidification of γ-Fe + UFe4B eutectic mixture (along l27) occurred at 1303 K (1030 °C). The solidification ended at 1258 K (985 °C) in E3 with the γ-Fe + UFe2 + UFe4B ternary eutectic mixture. The fact that l26 diverges from U7 and converges to U8 implies that U7 occurs at T > 1323 K (1050 °C) and that U8 occurs at T < 1323 K (1050 °C). On the other hand, l27 also diverges from U8, which enables the inference that this ternary reaction occurs at T > 1303 K (1030 °C). The configuration of U7 implies the convergence of l25, which diverges from the binary phase diagram at T = 1447 K (1174 °C)[14,15] without crossing the respective Alkemade line. This points to a monotonic temperature decrease in l25 and as a result, U7 occurs at T < 1447 K (1174 °C).

Rights and permissions

About this article

Cite this article

Dias, M., Carvalho, P.A., Mardolcar, U.V. et al. Liquidus Projection of the B-Fe-U Diagram: The Fe-Rich Corner. Metall Mater Trans A 44, 2270–2284 (2013). https://doi.org/10.1007/s11661-012-1559-9

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-012-1559-9