Abstract

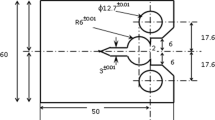

The dominant micromechanisms of dynamic failure initiation in high-strength ductile steels were investigated using 2.3Ni-1.3Cr-0.17C steel. Fracture experiments were conducted in three-point bend and one-point bend configurations. The influence of loading rate on the extent of each micromechanism in the fracture-initiation process was considered. The fracture surfaces consisted of a tunneled region and shear lips. The shear lips are characterized by microvoids. The tunneled region consists of large voids and microvoids that coalesced by impingement. At high loading rates, localized molten zones are observed at the tunnel-shear lip interface. The material-rate sensitivity causes a decrease in the size of the tunneled area at higher loading rates.

Similar content being viewed by others

References

J.R. Low, JR.: Eng. Fract. Mech., 1968, vol. 1, pp. 47–53.

T.B. Cox and J.R. Low, Jr.: Metall. Trans., 1974, vol. 5, pp. 1457–70.

R.H. Van Stone, T.B. Cox, J.R. Low, Jr., and J.A. Psioda: Int. Met. Rev., 1985, vol. 33, pp. 157–79.

A.S. Argon and J. Im: Metall. Trans. A, 1975, vol. 6A, pp. 839–51.

A.K. Zurek, W.R. Thissell, D.L. Tonks, R. Hixson, and F. Addessio: J. Phys. IV, 1997, vol. C3, pp. 903–08.

A.S. Argon, J. Im, and R. Safoglu: Metall. Trans. A, 1975, vol. 6A, pp. 825–37.

S.H. Goods and L.M. Brown: Acta Metall., 1979, vol. 27, pp. 1–15.

G. Le Roy, J.D. Embury, G. Edward, and M.F. Ashby: Acta Metall., 1981, vol. 29, pp. 1509–22.

P.F. Thomason: Acta Metall., 1985, vol. 33, pp. 1087–95.

P.F. Thomason: Acta Metall., 1993, vol. 41, pp. 2127–34.

D.L. Tonks, W.R. Thissell, A.K. Zurek, and R. Hixson: J. Phys. IV, 1997, vol. C3, pp. 841–46.

D.R. Curran, L. Seaman, and D.A. Shockey: Phys. Rep., 1987, vol. 147, pp. 253–388.

D.W. Yuan, J.F. Zarzour, and M.J. Kleinosky: Mater. Characterization, 1994, vol. 33, pp. 369–75.

Constraints Effects in Fracture, ASTM STP 1171, E.M. Hackett, K.H. Schwalbe, and R.H. Dodds, Jr.: eds., ASTM, Philadelphia, PA, 1993.

S. Lee, J.W. Rhyu, K. Cho, and J. Duffy: Metall. Trans. A, 1993, vol. 24A, pp. 901–12.

M.M. Carroll and A.C. Holt: J. Appl. Phys., 1972, vol. 43, pp. 1626–36.

R. Cortes: Int. J. Solids Struct., 1992, vol. 29, pp. 1339–50.

M. Ortiz and A. Molinari: J. Appl. Mech., 1992, vol. 59, pp. 48–58.

W. Tong and G. Ravichandran: J. Appl. Mech., 1995, vol. 62, pp. 633–39.

Y. Huang, J.W. Hutchinson, and V. Tvergaard: J. Mech. Phys. Solids, 1991, vol. 39, pp. 223–41.

S. Zhuang and G. Ravichandran: SM Repot No. 98-4, Graduate Aeronautical Laboratories, Caliofrnia Institute of Technology, Pasadena, CA, 1998.

J.R. Rice, P.C. Paris, and J.G. Merkle: Progress in Flaw Growth and Fracture Toughness Testing, ASTM STP 536, ASTM, Philadelphia PA, 1973, pp. 231–45.

C.F. Shih: J. Mech. Phys. Solids, 1981, vol. 29, pp. 305–26.

J.W. Hutchinson: J. Mech. Phys. Solids, 1968, vol. 16, pp. 13–31.

J.R. Rice and G.F. Rosengren: J. Mech. Phys. Solids, 1968, vol. 16, pp. 1–12.

P.R. Guduru, R.P. Singh, G. Ravichandran, and A.J. Rosakis: J. Mech. Phys. Solids, 1998, vol. 46, pp. 1997–2016.

R. Narasimhan and A.J. Rosakis: J. Appl. Mech., 1990, vol. 57, pp. 607–16.

R. Narasimhan, A.J. Rosakis, and B. Moran: Int. J. Fract., 1992, vol. 56, pp. 1–24.

R.M. McMeeking and D.M. Parks: Elastic-Plastic Francture, ASTM STP 668, ASTM, Philadelphia, PA, 1979, pp. 175–94.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Venkert, A., Guduru, P.R. & Ravichandran, G. An investigation of dynamic failure in 2.3Ni-1.3Cr-0.17C steel. Metall Mater Trans A 31, 1147–1154 (2000). https://doi.org/10.1007/s11661-000-0110-6

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-000-0110-6