Abstract

We describe an experimental technique to study the dynamic behavior of complex soft materials, based on high-speed microscopic imaging and direct measurements of dynamic forces and deformations. The setup includes high sensitivity dynamic displacement measurements based on geometric moiré interferometry and high-speed imaging for in-situ, full-field visualization of the complex micro-scale dynamic deformations. The method allows extracting dynamic stress-strain profiles both from the moiré interferometry and from the high-speed microscopic imaging. We discuss the advantages of using these two complementing components concurrently. We use this technique to study the dynamic response of vertically aligned carbon nanotube foams subjected to impact loadings at variable deformation rates. The same technique can be used to study other micro-structured materials and complex hierarchical structures.

Similar content being viewed by others

References

Lakes R (1993) Materials with structural hierarchy. Nature 36:511–515

Mayer G (2005) Rigid biological systems as models for synthetic composites. Science 310:1144–7. doi:10.1126/science.1116994

Ortiz C, Boyce M (2008) Bioinspired structural materials. Science 319:1053–1054. doi:10.1126/science.1154295

Lee J-H, Singer JP, Thomas EL (2012) Micro-/nanostructured mechanical metamaterials. Adv Mater 24:4782–810. doi:10.1002/adma.201201644

Maldovan M, Ullal CK, Jang J-H, Thomas EL (2007) Sub-micrometer scale periodic porous cellular structures: Microframes Prepared by holographic interference lithography. Adv Mater 19:3809–3813. doi:10.1002/adma.200700811

Yuan Z-Y, Su B-L (2006) Insights into hierarchically meso—macroporous structured materials. J Mater Chem 16:663. doi:10.1039/b512304f

Shim J, Shan S, Košmrlj A et al (2013) Harnessing instabilities for design of soft reconfigurable auxetic/chiral materials. Soft Matter 9:8198. doi:10.1039/c3sm51148k

Purslow PP, Wess TJ, Hukins DWL (1997) Collagen Orientation and molecular spacing during creep and stress-relaxation in soft connective tissues. J Exp Biol 201:135–142

Lattanzi L, Raney JR, De Nardo L et al (2012) Nonlinear viscoelasticity of freestanding and polymer-anchored vertically aligned carbon nanotube foams. J Appl Phys 111:074314. doi:10.1063/1.3699184

Yao H-B, Fang H-Y, Wang X-H, Yu S-H (2011) Hierarchical assembly of micro-/nano-building blocks: Bio-inspired rigid structural functional materials. Chem Soc Rev 40:3764–85. doi:10.1039/c0cs00121j

Teo EHT, Yung WKP, Chua DHC, Tay BK (2007) A carbon nanomattress: A new nanosystem with intrinsic, tunable, damping properties. Adv Mater 19:2941–2945. doi:10.1002/adma.200700351

Daraio C, Nesterenko VF, Jin S et al (2006) Impact response by a foamlike forest of coiled carbon nanotubes. J Appl Phys 100:064309. doi:10.1063/1.2345609

Lee J-H, Veysset D, Singer JP et al (2012) High strain rate deformation of layered nanocomposites. Nat Commun 3:1164. doi:10.1038/ncomms2166

Field JE, Walley SM, Proud WG, Goldrein HT, Siviour CR (2004) Review of experimental techniques for high rate deformation and shock studies. Int J Impact Eng 30:725–775. doi:10.1016/j.ijimpeng.2004.03.005

Ramesh KT (2008) Springer handbook of experimental solid mechanics: High rates and impact experiments. Springer, New York

Espinosa HD, Nemat-Nasser S (2000) ASM Handbook: Low-velocity impact testing. 539–559, American Society for Metals

Sutton MA, Orteu JJ, Schreier HW (2009) Image correlation for shape, motion and deformation measurements: Basic concepts, theory and applications. Springer, New York

Pan B, Qian K, Xie H, Asundi A (2009) Two-dimensional digital image correlation for in-plane displacement and strain measurement: A review. Meas Sci Technol 20(062001):17pp. doi:10.1088/0957-0233/20/6/062001

Hild F, Roux S (2006) Digital image correlation: From displacement measurement to identification of elastic properties - a review. Strain 42(2):69–80. doi:10.1111/j.1475-1305.2006.00258.x

Guduru PR, Rosakis AJ, Ravichandran G (2001) Dynamic shear bands: An investigation using high speed optical and infrared diagnostics. J Mech Mater 33:371–402. doi:10.1016/S0167-6636(01)00051-5

Kajberg J, Sundin KG, Melin LG, Ståhle P (2004) High strain-rate tensile testing and viscoplastic parameter identification using microscopic high-speed photography. Int J Plast 20:561–575. doi:10.1016/S0749-6419(03)00041-X

Koerber H, Xavier J, Camanho PP (2010) High strain rate characterisation of unidirectional carbon-epoxy IM7-8552 in transverse compression and in-plane shear using digital image correlation. J Mech Mater 42(11):1004–1019. doi:10.1016/j.mechmat.2010.09.003

Hutchens SB, Hall LJ, Greer JR (2010) In situ mechanical testing reveals periodic buckle nucleation and propagation in carbon nanotube bundles. Adv Funct Mater 20:2338–2346. doi:10.1002/adfm.201000305

Professional Plastics, http://www.professionalplastics.com/professionalplastics/content/Acetal_Delrin.pdf

Lu J, Suresh S, Ravichandran G (2003) Dynamic indentation for determining the strain rate sensitivity of metals. J Mech Phys Solids 51:1923–1938. doi:10.1016/j.jmps.2003.09.007

Oliver WC, Pharr GM (1992) An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J Mater Res 7(6):1564–1583. doi:10.1557/JMR.1992.1564

Qi HJ, Teo KBK, Lau KKS, Boyce MC, Milne WI, Robertson J, Gleason KK (2003) Determination of mechanical properties of carbon nanotubes and vertically aligned carbon nanotube forests using nanoindentation. J Mech Phys Solids 51:2213–2237. doi:10.1016/j.jmps.2003.09.015

He LH, Fujisawa N, Swain MV (2006) Elastic modulus and stress-strain response of human enamel by nano-indentation. Biomaterials 27:4388–98. doi:10.1016/j.biomaterials.2006.03.045

Hay J (2009) Introduction to instrumented indentation testing. Exp Tech 33:66–72. doi:10.1111/j.1747-1567.2009.00541.x

Subhash G, Koeppel BJ, Chandra A (1999) Dynamic indentation hardness and rate sensitivity in metals. J Eng Mater Technol 121(3):257–263. doi:10.1115/1.2812373

Misra A, Raney JR, De Nardo L, Craig AE, Daraio C (2011) Synthesis and characterization of carbon nanotube - polymer multilayer structures. 5(10):7713–21. doi: 10.1021/nn202262j

PCB Piezotronics, http://www.pcb.com/Products.aspx?m=200B02#.UmXHW2B5-kI

PCB Piezotronics, http://www.pcb.com/Products.aspx?m=200B03#.UmXHDGB5-kI

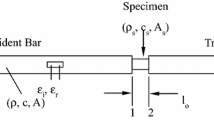

Davies EDH, Hunter SC (1963) The dynamic compression testing of solids by the method of the split Hopkinson pressure bar (SHPB). J Mech Phys Solids 11(3):155–179. doi:10.1016/0022-5096(63)90050-4

Song B, Chen W (2004) Dynamic stress equilibration in split hopkinson pressure bar tests on soft materials. Exp Mech 44:300–312. doi:10.1177/0014485104041543

Post D, Han B, Ifju P (1994) High sensitivity moiré: Experimental analysis for mechanics and materials. Springer, New York

Patorski K (1993) Handbook of the moiré fringe technique. Elsvier, New York

Cloud G (1998) Optical methods for engineering analysis. Cambridge University Press, Cambridge

Walker CA (1994) A historical review of moiré interferometry. Exp Mech 34(4):281–299. doi:10.1007/BF02325143

Raney JR, Misra A, Daraio C (2011) Tailoring the microstructure and mechanical properties of arrays of aligned multiwall carbon nanotubes by utilizing different hydrogen concentrations during synthesis. Carbon 49:3631–3638. doi:10.1016/j.carbon.2011.04.066

Cao A, Dickrell PL, Sawyer WG, Ghasemi-Nejhad MN, Ajayan PM (2005) Super-compressible foamlike carbon nanotube films. Science 310:1307–1310. doi:10.1126/science.1118957

Suhr J, Victor P, Ci L et al (2007) Fatigue resistance of aligned carbon nanotube arrays under cyclic compression. Nat Nanotechnol 2:417–21. doi:10.1038/nnano.2007.186

Misra A, Raney JR, De Nardo L, Craig AE, Daraio C (2011) Synthesis and characterization of carbon nanotube -polymer multilayer structures. ACS Nano 5:7713–21. doi:10.1021/nn202262j

Acknowledgments

We thank Prof. G. Ravichandran (California Institute of Technology) and Prof. M. Mello (Georgia Institute of Technology) for their useful suggestions. We acknowledge financial support from the Institute for Collaborative Biotechnologies (ICB) under the contract W911NF-09-D-0001 with the Army Research Office (ARO).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Thevamaran, R., Daraio, C. An Experimental Technique for the Dynamic Characterization of Soft Complex Materials. Exp Mech 54, 1319–1328 (2014). https://doi.org/10.1007/s11340-014-9896-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-014-9896-9