Abstract

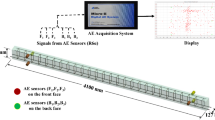

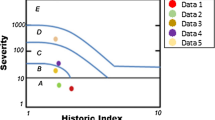

Acoustic emission was used to monitor the cracking mechanisms leading to the failure of scaled concrete beams having Glass Fiber Reinforced Polymer (GFRP) longitudinal reinforcement and no shear reinforcement. Dimensional scaling included that of the effective depth of the cross section, which is a key parameter associated with the scaling of shear strength; and maximum aggregate size, which affects the shear-resisting mechanism of aggregate interlock along shear (inclined) cracks. Five GFRP reinforced concrete (RC) beams with effective depth up to 290 mm and constant shear span-to-effective depth ratio of 3.1 were load tested under four-point bending. Two types of failures were observed: flexural, due to rupture of the GFRP reinforcement in the constant moment region; and shear, due to inclined cracking in either constant shear region through the entire section depth. Acoustic emission (AE) analyses were performed to classify crack types occurring at different points in the load history. The results of this study indicate that appropriate AE parameters can be used to discriminate between developing flexural and shear cracks irrespective of scale, and provide warning of impending failure irrespective of the failure mode (flexural and shear). In addition, AE source location enabled to accurately map crack growth and identify areas of significant damage activity. These outcomes attest to the potential of AE as a viable technique for structural health monitoring and prognosis systems and techniques.

Similar content being viewed by others

References

Matta F (2008) Industry/University Cooperative Research on Advanced Composite Reinforcement for Concrete: Translating Innovation into Sustainable Engineering Practice. Proc. NSF International Workshop on the Use of Fiber Reinforced Polymers for Sustainable Structures, Cairo, Egypt, May 22, CD-ROM, pp 13

American Concrete Institute (ACI) Committee 440 (2006) Guide for the Design and Construction of Structural Concrete Reinforced with FRP Bars—ACI 440.1R-06. ACI, Farmington Hills, MI

Canadian Standards Association (CSA) (2006) Canadian highway bridge design code—CAN/CSA-S6-06. CSA, Mississauga

American Association of State Highway and Transportation Officials (AASHTO) (2009) AASHTO LRFD bridge design guide specifications for GFRP-reinforced concrete bridge decks and traffic railings, 1st edn. AASHTO, Washington

American Concrete Institute (ACI) Committee 440 (2008) Specification for carbon and glass fiber-reinforced polymer bar materials for concrete reinforcement—ACI 440.6-08. ACI, Farmington Hills, MI

American Concrete Institute (ACI) Committee 440 (2008) Specification for construction with fiber-reinforced polymer reinforcing bars—ACI 440.5-08. ACI, Farmington Hills, MI

Gross SP, Yost JR, Dinehart DW, Svensen E, Liu N (2003) Shear Strength of Normal and High Strength Concrete Beams Reinforced with GFRP Bars. ASCE Special Publication: Proceedings of the International Conference on High Performance Materials in Bridges and Buildings, Kona, Hawaii, pp 426–437

Tureyen AK, Frosch RJ (2003) Concrete shear strength: another perspective. ACI Structural Journal 100(5):609–615

Matta F, Mazzoleni P, Zappa E, Sutton A, ElBatanouny M, Larosche A, Ziehl P (2012) Shear strength of FRP reinforced concrete beams without stirrups: verification of fracture mechanics formulation. ACI Special Publication Spring Convention 2012, Dallas, TX

Bentz EC, Massam L, Collins MP (2010) Shear strength of large concrete members with FRP reinforcement. J Compos Construct 14(6):637–646

Matta F, El-Sayed AK, Nanni A, Benmokrane B (2012) Size Effect on Concrete Shear Strength in Beams Reinforced with FRP Bars. In press ACI Structural Journal

Ziehl P (2008) Applications of acoustic emission evaluation for civil infrastructure. SPIE Smart Structures and Materials and Nondestructive Evaluation and Health Monitoring, San Diego, p 9

Pollock AA (1986) Classical Wave Theory in Practical AE Testing. Progress in AE III, Proceedings of the 8th International AE Symposium, Japanese Society for Nondestructive Testing, pp 708–721

ASTM E1316 (2006) Standard terminology for nondestructive examinations. American Standard for Testing and Materials, 1–33

ASTM E1067/E1067M-11 (2011) Standard practice for acoustic emission examination of Fiberglass Reinforced Plastic Resin (FRP) Tanks/Vessels. American Standard for Testing and Materials, 1–15

Fowler T, Blessing J, Conlisk P (1989) New directions in testing. Proc. 3rd International Symposium on AE from Composite Materials, Paris, France

Ono, K. (2010) Application of acoustic emission for structure diagnosis. KonferencjaNaukowa, pp. 317–341

Golaski L, Gebski P, Ono K (2002) Diagnostics of reinforced concrete by acoustic emission. J Acoust Emi 20:83–98

ElBatanouny M, Mangual J, Ziehl P, and Matta F (2011) Corrosion Intensity Classification in Prestressed Concrete using Acoustic Emission Technique. Proc. American Society for Nondestructive Testing (ASNT) Fall Conference and Quality Testing Show 2011, Palm Springs, CA, October 24–28, pp 10

Katsaga T, Sherwood EG, Collins MP, Young RP (2007) Acoustic emission imaging of shear failure in large reinforced concrete structures. Int J Fract 148(1):29–45

Collins MP, Kutchma D (1999) How safe are our large, lightly reinforced concrete beams, slabs, and footings. ACI Struct J 96(4):482–490

Bažant ZP, Yu Q, Gerstle W, Hanson J, Ju JW (2007) Justification of ACI 446 proposal for updating ACI code provisions for shear design of reinforced concrete beams. ACI Structural Journal, V. 104, No. 5, Sep.-Oct. 2007, pp 601–610

Kani GNJ (1967) How safe are our large reinforced concrete beams. ACI J 64(3):128–141

Fowler TJ, Blessing JA, Conlisk PJ, Swanson TL (1989) The Monpac system. Journal of Acoustic Emission. 8(3)

Tinkey BV, Fowler TJ, Klingner RE (2002) Nondestructive testing of prestressed bridge girders with distributed damage. Res Rep 1857–2:106

Shiotani T, Yuyama S, Li ZW, Ohtsu M (2001) Application of the AE improved b-value to qualitative evaluation of fracture process in concrete materials. J Acoust Emi 19:118–132

Ohtsu M, Okamoto T, Yuyama S (1998) Moment tensor analysis of acoustic emission for cracking mechanisms in concrete. ACI Structu J 95(2):87–95

Ohno K, Ohtsu M (2010) Crack classification in concrete based on acoustic emission. Construct Build Mater 24:2339–2346

Ohtsu M, Ono K (1984) A generalized theory of acoustic emission and green’s functions in a half space. J Acoust Emi 3(1):124–33

Aggelis DG (2011) Classification of crack mode in concrete by using acoustic emission parameters. Mech Res Comm 38:153–157

Aggelis DG, Soulioti DV, Sapouridis N, Barkoula NM, Paipetis AS, Matikas TE (2011) Acoustic emission characterization of the fracture process of fiber reinforced concrete. Construct Build Mater 25:4126–4131

Liu Z, Ziehl P (2009) Evaluation of RC beam specimens with AE and CLT criteria. ACI Struct J 106(3):1–12

Ziehl P, Galati N, Tumialan G, Nanni A (2008) In-situ evaluation of two rc slab systems—part II: evaluation criteria. ASCE J Perform Constr Facil 22(4):217–227

Gutenberg B, Richter CF (1954) Seismicity of the earth and associated phenomena, 2nd edn. Princeton University Press, Princeton

Sammonds PR, Meredith PG, Murrel SAF, Main IG (1994) Modelling the damage evolution in rock containing pore fluid by acoustic emission. Eurock ’94, Balkerna, Rotterdam, The Netherlands

Cox SJD, Meredith PG (1993) Microcrack formation and material softening in rock measured by monitoring acoustic emission. Int J Rock Mech Min Sci Geomech Abstr 30(1):11–21

Shiotani T, Ohtsu M, Ikeda K (2001) Detection and evaluation of AE waves due to rock deformation. Construct Build Mater 15(5–6):235–246

Colombo S, Main IG, Forde MC (2003) Assessing damage of reinforced concrete beam using b-value analysis of acoustic emission signals. J Mater Civil Eng 5–6:280–286

Aggelis DG, Mpalaskas AC, Ntalakas D, Matikas TE (2012) Effect of wave distortion on acoustic emission characterization of cementitious material. Construct Build Mater 35:183–190

Grosse CU, Ohtsu M (2008) Acoustic emission testing. Springer, Berlin

Acknowledgements

The authors gratefully acknowledge the joint support of the University of South Carolina (Department of Civil and Environmental Engineering), the Politecnico di Milano (Department of Mechanical Engineering), and the U.S. Department of Commerce, National Institute of Standards and Technology, Technology Innovation Program, Cooperative Agreement Number 70NANB9H9007. Special thanks are extended to Hughes Brothers, Inc. for having donated the GFRP bars and to Mr. Edward Deaver (Holcim US, Inc.) and the personnel of the USC Structures and Materials Laboratory for the technical assistance provided.

Author information

Authors and Affiliations

Corresponding author

Appendix A

Appendix A

Relevant terminology related to Acoustic Emission [40]

Each of the below listed parameters were calculated and given by the data acquisition program.

-

Amplitude: The largest voltage peak in the AE signal waveform; customarily expressed in decibels relative to 1 μV at the preamplifier input (dB) assuming a 40 dB preamp.

-

dB: A unit of measurement for AE signal amplitude A, defined by A (dB) = 20 log V p ; where V p is the peak signal voltage in μV referred to the preamplifier input.

-

Duration: The time from the first threshold crossing to the end of the last threshold crossing of the AE signal from the AE threshold.

-

Signal Strength: The measured area of the rectified AE signal with units proportional to volt seconds (the proportionality constant is specified by the AE instrument manufacturer).

-

Rise time: The time from an AE signal’s first threshold crossing to its peak.

-

Counts: The number of times the AE signal crosses the detection threshold.

-

Peak Frequency: The point in the power spectrum at which the peak magnitude occurs. The peak frequency is a 2 byte value reported in kHz.

-

RMS: The root mean square is a measure of continuous varying AE voltage. It is defined as the rectified time averaged AE signal measured on a linear scale and reported in volts.

-

RA value: The ratio between rise time and maximum amplitude in Volts from an AE signal.

Rights and permissions

About this article

Cite this article

ElBatanouny, M.K., Larosche, A., Mazzoleni, P. et al. Identification of Cracking Mechanisms in Scaled FRP Reinforced Concrete Beams using Acoustic Emission. Exp Mech 54, 69–82 (2014). https://doi.org/10.1007/s11340-012-9692-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-012-9692-3