Abstract

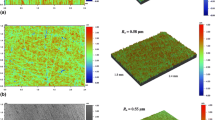

Friction influences the nature of transfer layer formed at the interface between tool and metal during sliding. In the present investigation, experiments were conducted using “Inclined Scratch Tester” to understand the effect of surface texture of hard surfaces on coefficient of friction and transfer layer formation. EN8 steel flats were ground to attain surfaces of different textures with different roughness. Then super purity aluminium pins were scratched against the prepared steel flats. Scanning electron micrographs of the contact surfaces of pins and flats were used to reveal the morphology of transfer layer. It was observed that the coefficient of friction and the formation of transfer layer depend primarily on the texture of hard surfaces, but independent of surface roughness of hard surfaces. It was observed that on surfaces that promote plane strain conditions near the surface, the transfer of material takes place due to the plowing action of the asperities. But, on a surface that promotes plane stress conditions the transfer layer was more due to the adhesion component of friction. It was observed that the adhesion component increases for surfaces that have random texture but was constant for the other surfaces.

Similar content being viewed by others

References

Rymuza Z. (1996) Wear 199: 187

Kato K. (2000) Wear 241: 151

Bello D.O., Walton S. (1987) Tribol. Int. 20: 59

Rasp W., Wichern C.M. (2002) J. Mater. Process. Tech. 125–126: 379

Schedin E. (1994) Wear 179: 123

Kim D.E., Suh N.P. (1991) Wear 149: 199

Hu Z.M., Dean T.A. (2000) Int. J. Mach. Tool. Manu. 40: 1637

Lanzon J.M., Cardew-Hall M.J., Hodgson P.D. (1998) J. Mater. Process. Tech. 80–81: 251

Saha P.K., Wilson W.R.D., Timsit R.S. (1996) Wear 197: 123

Lovell M.R., Deng Zhi, Khonsari M.M. (2000) Trans. of ASME 122: 856

Lakshmipathy R., Sagar R. (1992) Int. J. Mach. Tool. Manu. 32: 685

Wang L.Y., Yin Z.F., Zhang J., Chen C., Hsu S. (2000) Wear 237: 155–162

Feder J. (1988) Fractals Plenum Press, New York

Hasegawa M., Liu J., Okuda K., Nunobiki M. (1996) Wear 192: 40

Bowden F.P., Tabor D. (1954) The Friction and Lubrication of Solids, Clarendon, Oxford

George E. Dieter (2000) Mechanical Metallurgy. McGraw-Hill, New York

Faulkner A., Arnell R.D. (2000) Wear 242: 114

Satish V. Kailas and Pradeep Lancy Menezes, Proceedings of International Seminar on Metal Forming–Process Design and Optimization, (Indian Institute of Science, India, 2003) pp. 124–143

Challen J.M., Oxley P.L.B. (1979) Wear 53: 229–243

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Menezes, P., Kishore & Kailas, S. Studies on friction and transfer layer: role of surface texture. Tribol Lett 24, 265–273 (2006). https://doi.org/10.1007/s11249-006-9129-1

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11249-006-9129-1