Abstract

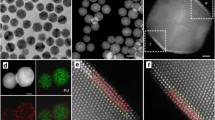

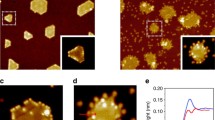

Selective, active, and robust catalysts are necessary for the efficient utilization of new feedstocks. Face-selective catalysts can precisely modify catalytic properties, but are often unstable under reaction conditions, changing shape and losing selectivity. Herein we report a method for synthesizing stable heterogeneous catalysts in which the morphology and selectivity can be tuned precisely and predictably. Using nanocrystal supports, we epitaxially stabilize specific active phase morphologies. This changes the distribution of active sites of different coordination, which have correspondingly different catalytic properties. Specifically, we utilize the different interfacial free-energies between perovskite titanate nanocube supports with different crystal lattice dimensions and a platinum active phase. By substituting different sized cations into the support, we change the lattice mismatch between the support and the active phase, thereby changing the interfacial free-energy, and stabilizing the active phase in different morphologies in a predictable manner. We correlate these changes in active phase atomic coordination with changes in catalytic performance (activity and selectivity), using the hydrogenation of acrolein as a test reaction. The method is general and can be applied to many nanocrystal supports and active phase combinations.

Similar content being viewed by others

Notes

For completeness, changing the lattice mismatch is not the only way to change the interfacial free-energy and therefore the degree of wetting. Changing the bonding interactions or the composition of the interface will also change the interfacial free-energy. For example, changing to a more oxophilic active phase metal would increase the bond strength and lower the interfacial free-energy. By maintaining the same active phase and substituting one chemically similar cation in the support we minimize such effects in order isolate the effect of the change in lattice mismatch. Preliminary catalytic results on a sample of Pt on commercial SrTiO3 (non-nanocrystal) showed a lower selectivity than either the SrTiO3 or Ba0.5Sr0.5TiO3 support. These should have the same bonding effects as nanocrystal SrTiO3, and support our hypothesis that the structural effect is paramount. However, at this time we cannot completely rule out the possibility that bonding effects make some contribution in addition to the structural effects.

References

Boudart M (1969) Catalysis by supported metals. Adv Catal 20:153–166

Enterkin JA, Poeppelmeier KR, Marks LD (2011) Oriented catalytic platinum nanoparticles on high surface area strontium titanate nanocubes. Nano Lett 11(3):993–997. doi:10.1021/nl104263j

Enterkin JA, Setthapun W, Elam JW, Christensen ST, Rabuffetti FA, Marks LD, Stair PC, Poeppelmeier KR, Marshall CL (2011) Propane oxidation over Pt/SrTiO3 nanocuboids. ACS Catalysis 1(6):629–635. doi:10.1021/cs200092c

DOE-BES (2007) Basic research needs: catalysis for energy. U.S. Department of Energy, Basic Energy Sciences

Somorjai GA, Carrazza J (1986) Structure sensitivity of catalytic reactions. Ind Eng Chem Fundam 25(1):63–69

Davis SM, Zaera F, Somorjai GA (1982) Surface-structure and temperature-dependence of light-alkane skeletal rearrangement reactions catalyzed over platinum single-crystal surfaces. J Am Chem Soc 104(26):7453–7461

Hu LH, Sun KQ, Peng Q, Xu BQ, Li YD (2010) Surface active sites on Co3O4 nanobelt and nanocube model catalysts for CO oxidation. Nano Res 3(5):363–368. doi:10.1007/s12274-010-1040-2

Behafarid F, Cuenya BR (2011) Nanoepitaxy using micellar nanoparticles. Nano Lett 11(12):5290–5296. doi:10.1021/Nl2027525

Rabuffetti FA, Kim HS, Enterkin JA, Wang YM, Lanier CH, Marks LD, Poeppelmeier KR, Stair PC (2008) Synthesis-dependent first-order Raman scattering in SrTiO3 nanocubes at room temperature. Chem Mater 20(17):5628–5635. doi:10.1021/Cm801192t

Deak DS (2007) Strontium titanate surfaces. Mater Sci Technol 23(2):127–136. doi:10.1179/174328407x154383

Kienzle DM, Marks LD (2012) Surface transmission electron diffraction for SrTiO3 surfaces. Cryst Eng Commun 14(23):7833–7839. doi:10.1039/C2CE25204J

Wulff G (1901) On the question of speed of growth and dissolution of crystal surfaces. Z Krystallogr Minera 34(5/6):449–530

Winterbottom WL (1967) Equilibrium shape of a small particle in contact with a foreign substrate. Acta Metall 15(2):303

Polli AD, Wagner T, Gemming T, Ruhle M (2000) Growth of platinum on TiO2- and SrO-terminated SrTiO3(100). Surf Sci 448(2–3):279–289

Feng ZX, Kazimirov A, Bedzyk MJ (2011) Atomic imaging of oxide-supported metallic nanocrystals. ACS Nano 5(12):9755–9760. doi:10.1021/Nn203273e

Christensen ST, Elam JW, Rabuffetti FA, Ma Q, Weigand SJ, Lee B, Seifert S, Stair PC, Poeppelmeier KR, Hersam MC, Bedzyk MJ (2009) Controlled growth of platinum nanoparticles on strontium titanate nanocubes by atomic layer deposition. Small 5(6):750–757. doi:10.1002/smll.200801920

Setthapun W, Williams WD, Kim SM, Feng H, Elam JW, Rabuffetti FA, Poeppelmeier KR, Stair PC, Stach EA, Ribero FH, Miller JT, Marshall CL (2010) Genesis and evolution of surface species during Pt atomic layer deposition on oxide supports characterized by in Situ XAFS analysis and water-gas shift reaction. J Phys Chem C 114(21):9758–9771. doi:10.1021/Jp911178m

Swanson HE, Tatge E (1953) Standard X-ray diffraction powder patterns I, vol 1. National Bureau of Standards Monoraph. US Department of Commerce, National Bureau of Standards, Washington DC

Kliewer CJ, Bieri M, Somorjai GA (2009) Hydrogenation of the α, β-unsaturated aldehydes acrolein, crotonaldehyde, and prenal over Pt single crystals: a kinetic and sum-frequency generation vibrational spectroscopy study. J Am Chem Soc 131(29):9958–9966

Wu H, Tang R, He Q, Liao XP, Shi B (2009) Highly stable Pt nanoparticle catalyst supported by polyphenol-grafted collagen fiber and its catalytic application in the hydrogenation of olefins. J Chem Technol Biot 84(11):1702–1711. doi:10.1002/Jctb.2234

Gyorffy N, Paal Z (2008) Acrolein hydrogenation on PdPt powder catalysts prepared by colloid synthesis. J Mol Catal A 295(1–2):24–28. doi:10.1016/j.molcata.2008.08.012

Hoang-Van C, Zegaoui O (1997) Studies of high surface area Pt/MoO3 and Pt/WO3 catalysts for selective hydrogenation reactions II. Reactions of acrolein and allyl alcohol. Appl Catal A 164(1–2):91–103

Komanicky V, Iddir H, Chang KC, Menzel A, Karapetrov G, Hennessy D, Zapol P, You H (2009) Shape-dependent activity of platinum array catalyst. J Am Chem Soc 131(16):5732–5733. doi:10.1021/Ja900459w

Acknowledgments

The authors thank Mihai Anitescu for assistance with the statistical analysis. This work was funded in part by Institute for Atom-efficient Chemical Transformations, an Energy Frontier Research Center, funded through the U.S. Department of Energy, Office of Basic Energy Sciences; and in part by the Northwestern University Institute for Catalysis in Energy Processing, funded through the US Department of Energy, Office of Basic Energy Science (award number DE-FG02-03-ER15457). The electron microscopy was accomplished at the Electron Microscopy Center for Materials Research at Argonne National Laboratory, a U.S. Department of Energy Office of Science Laboratory operated under Contract No. DE-AC02-06CH11357 by UChicago Argonne, LLC.

Author information

Authors and Affiliations

Corresponding author

Additional information

James A. Enterkin and Robert M. Kennedy contributed equally to this work.

Rights and permissions

About this article

Cite this article

Enterkin, J.A., Kennedy, R.M., Lu, J. et al. Epitaxial Stabilization of Face Selective Catalysts. Top Catal 56, 1829–1834 (2013). https://doi.org/10.1007/s11244-013-0118-y

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11244-013-0118-y