Abstract

Reaction of triose sugars with ammonia under anaerobic conditions yielded autocatalytic products. The autocatalytic behavior of the products was examined by measuring the effect of the crude triose–ammonia reaction product on the kinetics of a second identical triose–ammonia reaction. The reaction product showed autocatalytic activity by increasing both the rate of disappearance of triose and the rate of formation of pyruvaldehyde, the product of triose dehydration. This synthetic process is considered a reasonable model of origin-of-life chemistry because it uses plausible prebiotic substrates, and resembles modern biosynthesis by employing the energized carbon groups of sugars to drive the synthesis of autocatalytic molecules.

Similar content being viewed by others

Introduction

Life uses sugars as its primary carbon substrate because sugars are kinetically and thermodynamically unstable towards self-transformations that yield essential biochemicals (Weber 1997, 2000, 2002, 2004). Amino acids and fatty acids are made from sugars by energetically favorable pathways involving redox-disproportionation of sugar carbon groups, and nucleosides are synthesized using sugars and sugar-derived amino acids (Zubay 1983; Weber 2000, 2002). In fact, anaerobic sugar fermenters can make all of their essential biochemicals from sugars as the only source of carbon and energy (Gottschalk 1986).

In addition to being the optimal biosynthetic carbon-substrate, sugars are very attractive prebiotic substrates, because they (a) are readily made from the plausible prebiotic precursors – formaldehyde and glycolaldehyde, and (b) are excellent substrates for chemical synthesis of organic molecules and polymers considered relevant to the origin of life (Weber 2001 refer. therein). Sugars spontaneously react in the presence and absence of amines (or ammonia) to give numerous aliphatic and aromatic products, like hydroxy acids, pyruvate, amino acids, furans, imidazoles, pyridines, and pyrroles (Grimmett 1965; Kort 1970; Weber 1984, 1985, 1998; Ledl and Schleicher 1990). Sugar transformations also yield melanoidin polymers (Ellis 1959; Cammerer et al. 2002; Martins and Van Boekel 2005) that in some cases integrate into growing semi-solid microspherules (Weber 2005). Moreover, the observation that sugar-ammonia reactions yield small molecules, like amines and organic acids that are known to catalyze sugar transformation reactions (Weber 2001; Rizzi 2004) suggests that sugar-ammonia reactions could yield autocatalytic products. To directly examine the autocatalytic activity of products of a sugar-ammonia reaction, we report here measurements of the ability of triose–ammonia reaction products to catalyze an identical triose–ammonia reaction.

Materials and Methods

Materials

DL-Glyceraldehyde dimer (95%), dihydroxyacetone (97%), pyruvic aldehyde, ammonium chloride (99.998%), mercaptoethanol (98%), glacial acetic acid (99.8%), sodium hydroxide (99.99%), 37% hydrochloric acid (99.999%) were obtained from Aldrich; and sodium acetate trihydrate, 2,4-dinitrophenylhydrazine (DNPH), o-phthaldialdehyde, acetonitrile (HPLC grade), Millipore syringe filter units (Millex Durapore 25 mm, 0.22 μm) were obtained from Sigma.

Reaction Procedures

Reaction-1 was carried out under argon at 65°C in a 100 ml Pyrex bottle using 18 ml of a solution containing 100 mM of commercial DL-glyceraldehyde (that actually contained 64% glyceraldehyde and 36% dihydroxyacetone), 100 mM ammonium chloride, and 40 mM sodium acetate (pH 5.0). The reaction pH was controlled by a Brinkman pH stat (Metrohm 718 Stat Titrino) that used a Cole–Palmer autoclavable combination pH electrode (C-05662-15). Reaction solutions were prepared in a sterile laminar flow hood using a dry-heat sterilized reaction bottle fitted with an ethanol-sterilized Teflon gas-tight cap that had airtight fittings for the pH electrode, 1 M NaOH titrant, argon gas, and syringe sampling septum. The reaction solution and the argon gas were sterilized by filtration using Millipore syringe filters (0.22 μm). The triose reagent (143 mM commercial DL-glyceraldehyde dimer in 46 mM sodium acetate at pH 5.0) that was used to prepare the reaction solution was heated at 65°C for 30 min in order to quickly depolymerize triose dimers. Our examination of this depolymerization reaction had shown that 30 min was the minimum time required for triose depolymerization at 65°C. At timed intervals 50 μl aliquots of the reaction solution were removed with a syringe and frozen at −80°C until analyzed for carbonyl compounds by HPLC. The ammonia concentration of the final reaction product was measured by HPLC to estimate ammonia incorporation into organics. Reaction-2 was identical to Reaction-1, except that it contained an additional 20% of the crude product of Reaction-1. The volumes of the reagent solutions used to prepare Reaction-2 were adjusted to compensate for dilution due to the added 20% of Reaction-1. To obtain a 100 mM concentration of NH4Cl in Reaction-2, 7% of additional NH4Cl was added to Reaction-2 to make up for ammonia incorporation into organics in the portion of Reaction-1 added to Reaction-2.

HPLC Analysis

Analysis of carbonyl compounds

Glyceraldehyde, dihydoxyacetone, and pyruvaldehyde were measured by HPLC of their 2,4-dinitrophenylhydrazine (DNPH) derivatives (Steinberg and Kaplan 1984). A 7 μl aliquot of reaction solution was diluted with 93 μl of water, and a 7 μl aliquot of the resulting solution was reacted at ambient temperature for 40 min with 793 μl of DNPH reagent (60 μl of saturated DNPH in 2N HCl filtered through a 0.2 μm nylon Centrex unit, 100 μl of acetonitrile, and 633 μl of water). A 20 μl aliquot was analyzed by HPLC. HPLC analysis used a Beckman Model 126 HPLC System equipped with a Beckman UV-visible detector. Dinitrophenylhydrazine (DNPH) derivatives of carbonyl compounds were monitored by their absorbance at 360 nm. The carbonyl compound-DNPH derivatives were separated on a Beckman Ultrasphere C18 column (250 × 4.6 mm) eluted at 1.0 ml/min using eluent (A) 25 mM sodium acetate (pH 5.5)/acetonitrile (99:1 v/v), and eluent (B) 25 mM sodium acetate (pH 5.5)/acetonitrile (20:80 v/v). The column was initially equilibrated with 52% eluent (B), and 7 min after injection the solvent mixture was changed linearly to 100% eluent (B) over 5 min, and maintained at 100% eluent (B) for 7 min. Elution times of the carbonyl compound-DNPH derivatives were glycolate (3.08 min), pyruvate (3.21 min), glyceraldehyde (4.82 min), dihydroxyacetone (5.90 min), glycolaldehyde (6.94 min), DNPH (7.33 min), formaldehyde (12.81 min), and pyruvaldehyde (diDNPH 18.22 min).

Analysis of ammonium ion

Ammonium ion was measured by HPLC of its o-phthaldialdehyde-mercaptoethanol derivative (OPA-ME) (Gardner and St. John 1991). A 5 μl aliquot of the final reaction solution was added to 995 μl of water, and then a 3 μl aliquot of the dilution was reacted at 65°C for 3.5 min with 197 μl of OPA-mercaptoethanol reagent (3 mg of OPA, 20 ul of 1 M mercaptoethanol, and 1,980 μl of 100 mM sodium phosphate-pH 6.7). A 20 μl aliquot was analyzed by HPLC. HPLC analysis used a Beckman Model 126 HPLC system equipped with a JASCO fluorescence detector. The ammonia-(OPA-ME) derivative was monitored by its fluorescence (excitation 410 nm, emission 470 nm). The ammonia-(OPA-ME) derivative was separated on a Beckman Ultrasphere C18 column (250 × 4.6 mm) eluted at 1.0 ml/min with eluent (A) 25 mM sodium acetate (pH 5.5)/acetonitrile (99:1 v/v), and eluent (B) 50 mM sodium acetate (pH 5.5)/acetonitrile (40:60 v/v). The column was initially equilibrated with 25% eluent (B), and 0.5 min after injection the solvent mixture was changed linearly to 95% eluent (B) over 15 min, and maintained at 95% eluent (B) for 3 min. The elution time of the ammonia-(OPA-ME) derivative was 13.43 min.

Results and Discussion

Autocatalytic Activity of the Triose–Ammonia Reaction Product

Previous investigations have shown that sugar-ammonia reactions yield small molecules (amines and organic acids) that are known from separate studies to catalyze various sugar transformations (Grimmett 1965; Kort 1970; Weber 1984, 1985, 1998; Ledl and Schleicher 1990). However, there have been no studies reporting catalysis of a sugar-ammonia reaction by its own chemical product. To evaluate the ability of the product of a sugar-ammonia reaction to catalyze its own reactions, that is, act autocatalytically, we measured the time course of triose–ammonia reactions in the absence and presence of an added portion of triose–ammonia reaction product. Figure 1 shows the time course of triose disappearance and pyruvaldehyde formation of two separate triose–ammonia reactions that were carried out under the same conditions and reactant concentrations, except that Reaction-2 contained a 20% portion of the product of Reaction-1. A comparison of the initial rate of pyruvaldehyde synthesis of Reaction-1 (17 mM/d) with that of Reaction-2 (37 mM/d) shows that pyruvaldehyde formation in Reaction-2 is roughly 2.2-fold faster than in Reaction-1. The actual increase of pyruvaldehyde formation in Reaction-2 is probably greater than the 2.2-fold estimate, because the eventual disappearance of pyruvaldehyde is faster in Reaction-2 compared to Reaction-1. Triose disappearance from 0.083 to 0.42 day for Reaction-1 (65 mM/d) and Reaction-2 (96 mM/d) shows that triose consumption in Reaction-2 is about 1.5 times faster than in Reaction-1. The faster rates of pyruvaldehyde synthesis and triose disappearance observed for Reaction-2 is attributed to the catalytic action of triose–ammonia product added to Reaction-2 – the only difference between the two reactions. These values indicate that at 100% the triose–ammonia reaction product could cause about an 11-fold increase in the rate of pyruvaldehyde formation, and a sevenfold increase in the rate of triose disappearance. From the initial rates, the lower limit of the percent conversion of triose to pyruvaldehyde is estimated to be about 26% for Reaction-1 and 38% for Reaction-2. This difference in efficiency of pyruvaldehyde formation provides evidence that the triose dehydration reaction yielding pyruvaldehyde is a principal catalytic target of the triose–ammonia products added to Reaction-2.

Time course of reaction of 100 mM triose with 100 mM ammonium chloride in 40 mM sodium acetate (pH 5.0) at 65°C. The triose concentration shown is the sum of the analyzed concentrations of glyceraldehyde and dihydroxyacetone. Reaction-1 was carried out for 7 days as described without additional reagents. Reaction-2 was identical to Reaction-1, except that it contained an additional of 20% of the crude product of Reaction-1. Not shown, the yields at 3 days and 7 days were: Reaction-1 (triose 3 days (12.1 mM), 7 days (3.64 mM), pyruvaldehyde 3 days (0.98 mM), 7 days (0.043 mM)); and Reaction-2 (triose 3 days (11.8 mM), 7 days (3.58 mM), pyruvaldehyde 3 days (0.80 mM), 7 days (0.80 mM))

The plot inserted in the top-right of Fig. 1 shows that the commercial DL-glyceraldehyde initially contained about 36% dihydroxyacetone and 64% glyceraldehyde. Over the two days of reaction depicted in Fig. 1 the ratio of dihydroxyacetone to glyceraldehyde increased from about 0.6 to 1.5. At 7 days (the end of the reactions) the ratio had increased further to about 15. This change in the dihydroxyacetone to glyceraldehyde ratio is expected because the isomerization of glyceraldehyde to dihydroxyacetone is energetically favorable, and the dehydration of glyceraldehyde to pyruvaldehyde is faster than that of dihydroxyacetone (Weber 2004 refer. therein).

Sugar-Ammonia Reactions

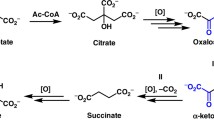

Figure 2 shows sugar transformation reactions that probably occur in the triose–ammonia reaction. As shown in the figure, the two reactions we measured are the reversible isomerization of glyceraldehyde to dihydroxyacetone (ΔG°′∼ −1 kcal/mol), and the irreversible β-dehydration of glyceraldehyde and dihydroxyacetone to pyruvaldehyde (ΔG°′∼ −11 kcal/mol) (Weber 2002, 2004). Other likely reactions are: (1) mixed aldol condensations involving trioses and pyruvaldehyde that generate branched and linear hexoses, 3-deoxyhexosuloses, and other dicarbonyl products (Gutsche et al. 1967; Konigstein and Fedoronko 1973; Weber 2001), (2) anaerobic intra- and intermolecular redox reactions that convert trioses and pyruvaldehyde to organic acids such as glyoxylic acid, pyruvic acid, and lactic acid (Weber 1984, 1998), (3) α-ketoaldehyde deformylations that convert pyruvaldehyde to acetaldehyde and formic acid, and 3-deoxyhexosuloses to 2-deoxypentoses (like 2-deoxyribose) and formic acid (Ledl and Schleicher 1990; Weber 2001), and (4) dehydrations involving sugar hemiacetal rings that yield substituted furans (Ledl and Schleicher 1990; Gerrard 2002). Most of these types of sugar transformations are known to be catalyzed by amines, ammonia, and organic acids (Ledl and Schleicher 1990; Weber 2001). As shown in Fig. 2, amines (incl. ammonia) also react with sugars and their C,H,O-products yielding a variety of nitrogen containing products, such as amino acids, imidazoles, pyrazines, pyridines, pyrroles, and soluble and insoluble melanoidin polymers (Grimmett 1965; Kort 1970; Weber 1985, 1998; Ledl and Schleicher 1990; Gerrard 2002). These types of amine and organic acid products are probably responsible for the observed autocatalytic activity of the triose–ammonia reaction product.

Prebiotic Sugar Synthesis

Sugars have a robust transformation chemistry because they contain a carbonyl group that confers high reactivity, and alcohol groups that have the largest self-transformation energy per carbon compared to other carbon groups (Weber 1997, 2000, 2002, 2004). Sugars are also plausible prebiotic substrates because they can be readily synthesized from the simple one- and two-carbon precursors, formaldehyde and glycolaldehyde (Mizuno and Weiss 1974; Schwartz and de Graaf 1993; Weber 2001). Formaldehyde, the substrate of sugar synthesis, has been synthesized under a variety of plausible prebiotic conditions (Miller 1957; Hubbard et al. 1971; Bar-Nun and Hartman 1978; Chittenden and Schwartz 1981; Miller and Schlesinger 1984). Especially attractive is the photochemical synthesis of formaldehyde in the prebiotic atmosphere (Ferris and Chen 1975; Pinto et al. 1980; Canuto et al. 1983; Kasting and Pollack 1984; Chang 1993), and hydrosphere (Ferris and Chen 1975; Aurian-Blajeni et al. 1980; Halmann et al. 1981). Glycolaldehyde could have been synthesized from formaldehyde by the formose reaction cycle (Mizuno and Weiss 1974; Schwartz and de Graaf 1993), or possibly generated photochemically in the atmosphere (Bacher et al. 2001). Ammonia could have been generated by the reduction of nitrite (or nitrate) by soluble ferrous ion or ferrous sulfide (Summers and Chang 1993; Summers 2005). These prebiotic processes could have provided a reliable source of substrates for a sugar-based origins process that has the potential to directly develop into the modern biosynthesis that also uses sugars as its primary carbon substrate (Weber 1997, 1998, 2000, 2001).

References

Aurian-Blajeni B, Halmann M, Manassen J (1980) Photoreduction of carbon dioxide and water into formaldehyde and methanol on semiconductor materials. Sol Energy 25:165–175

Bacher C, Tyndall GS, Orlando JJ (2001) The atmospheric chemistry of glycolaldehyde. J Atmos Chem 39:171–189

Bar-Nun A, Hartman H (1978) Synthesis of organic compounds from carbon monoxide by UV photolysis. Orig Life 9:93–101

Cammerer B, Jalyschko W, Kroh LW (2002) Intact carbohydrate structures as part of the melanoidin skeleton. J Agric Food Chem 50:2083–2087

Canuto VM, Levine TR, Augustsson CL, Imhoff CL, Giampapa MS (1983) The young sun and the atmosphere and photochemistry of the early earth. Nature 305:281–286

Chang S (1993) Prebiotic synthesis in planetary environments. In: Greenberg JM, Mendoza-Gomez CX, Pirronello V (eds) The chemistry of life’s origins (NATO ASI Series C). Kluwer, Dordrecht The Netherlands, pp 259–299

Chittenden GJF, Schwartz AW (1981) Prebiotic photocatalytic reactions. BioSystems 14:15–32

Ellis GP (1959) The Maillard reaction. In: Wolfrom ML, Tipson RS (eds) Advances in carbohydrate chemistry. Academic, New York, pp 63–134

Ferris JP, Chen CT (1975) Chemical evolution. XXVI. Photochemistry of methane, nitrogen, and water mixtures as a model for the atmosphere of the primitive earth. J Am Chem Soc 97:2962–2967

Gardner WS, St. John PA (1991) High-Performance liquid chromatographic method to determine ammonium ion and primary amines in sea water. Anal Chem 63:537–540

Gerrard JA (2002) New aspects of an AGEing chemistry. Aust J Chem 55:299–310

Gottschalk G (1986). Bacterial metabolism. Springer, Berlin Heidelberg New York, pp 162–169

Grimmett MR (1965) Formation of heterocyclic compounds from carbohydrates and ammonia. Rev Pure Appl Chem 15:101–108

Gutsche CD, Redmore D, Buriks RS, Nowotny K, Grassner H, Armbruster CW (1967) Base-catalyzed triose condensations. J Am Chem Soc 89:1235–1245

Halmann M, Aurian-Blajeni B, Bloch S (1981) Photoassisted carbon dioxide reduction and formation of two- and three-carbon compounds. In: Wolman Y (ed) Origin of life. Reidel, New York, pp 143–150

Hubbard JS, Hardy JP, Horowitz NH (1971) Photocatalytic production of organic compounds from CO and H2O in a simulated martian atmosphere. Proc Natl Acad Sci USA 68:574–578

Kasting JF, Pollack JB (1984) Effects of high CO2 levels on surface temperature and atmospheric oxidation state of the early earth. J Atmos Chem 1:403–428

Konigstein J, Fedoronko M (1973) Study of reaction kinetics of methylglyoxal in alkaline medium. Collection Czechoslov. Chem Commun 38:3801–3810

Kort MJ (1970) Reactions of free sugars with aqueous ammonia. In: Tipson RS, Horton D (eds) Advances in carbohydrate chemistry and biochemistry. Academic, New York, pp 311–349

Ledl F, Schleicher E (1990) New aspects of the Maillard reaction in foods and in the human body. Angew Chem Int Ed Engl 29:565–706

Martins SIFS, Van Boekel MAJS (2005) A kinetic model for the glucose/glycine Maillard reaction pathways. Food Chem 90:257–269

Miller SL (1957) The formation of organic compounds on the primitive earth. Ann NY Acad Sci 69:260–275

Miller SL, Schlesinger G (1984) Carbon and energy yields in prebiotic syntheses using atmospheres containing CH4, CO and CO2. Orig Life 14:83–90

Mizuno T, Weiss AH (1974) Synthesis and utilization of formose sugars. In: Tipson RS, Horton D (eds) Advances in carbohydrate chemistry and biochemistry. Academic, New York, pp 173–215

Pinto JP, Gladstone GR, Yung YL (1980) Photochemical production of formaldehyde in earth’s primitive atmosphere. Science 210:183–185

Rizzi GP (2004) Role of phosphate and carboxylate in Maillard browning. J Agric Food Chem 52:953–957

Schwartz AW, de Graaf RM (1993) The prebiotic synthesis of carbohydrates: a reassessment. J Mol Evol 35:101–106

Steinberg S, Kaplan IR (1984) The determination of low molecular weight aldehydes in rain, fog and mist by reversed phase liquid chromatography of the 2, 4-dinitrophenylhydrazone derivatives. Int J Environ Anal Chem 18:253–266

Summers DP (2005) Ammonia formation by the reduction of nitrate/nitrite by FeS: ammonia formation under acidic conditions. Orig Life Evol Biosph 35:299–312

Summers D, Chang S (1993) Prebiotic ammonia from reduction of nitrite by iron (II) on the early earth. Nature 365:630–633

Weber AL (1984) Prebiotic formation of ‘energy-rich’ thioesters from glyceraldehyde and N-acetylcysteine. Orig Life 15:17–27

Weber AL (1985) Alanine synthesis from glyceraldehyde and ammonium ion in aqueous solution. J Mol Evol 21:351–355

Weber AL (1997) Energy from redox disproportionation of sugar carbon drives biotic and abiotic synthesis. J Mol Evol 44:354–360

Weber AL (1998) Prebiotic amino acid thioester synthesis: thiol-dependent amino acid synthesis from formose substrates (formaldehyde and glycolaldehyde) and ammonia. Orig Life Evol Biosph 28:259–270

Weber AL (2000) Sugars as the optimal biosynthetic carbon substrate of aqueous life throughout the universe. Orig Life Evol Biosph 30:33–43

Weber AL (2001) The sugar model: catalysis by amines and amino acid products. Orig Life Evol Biosph 31:71–86

Weber AL (2002) Chemical constraints governing the origin of metabolism: the thermodynamic landscape of carbon group transformations under mild aqueous conditions. Orig Life Evol Biosph 32:333–357

Weber AL (2004) Kinetics of organic transformations under mild aqueous conditions: implications for the origin of life and its metabolism. Orig Life Evol Biosph 34:473–495

Weber AL (2005) Growth of organic microspherules in sugar-ammonia reactions. Orig Life Evol Biosph 35:523–536

Zubay G (1983) Biochemistry. Addison-Wesley, London, pp 487–498, 698–713, 825–872

Acknowledgments

I thank Esther Varon for technical assistance in these studies. This investigation was supported by a grant (NNA05CP68A) from the Exobiology Program of the National Aeronautics and Space Administration.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Weber, A.L. The Sugar Model: Autocatalytic Activity of the Triose–Ammonia Reaction. Orig Life Evol Biosph 37, 105–111 (2007). https://doi.org/10.1007/s11084-006-9059-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11084-006-9059-9