Abstract

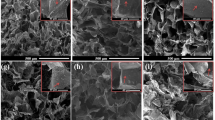

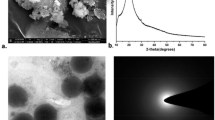

In the hereby presented work the authors describe a technique of high-compression-resistant biodegradable bone scaffold preparation. The methodology is based on the agglomeration of chitosan (CH) and chitosan/β-tricalcium phosphate (CH/TCP) microspheres and represents a novel approach to 3D matrices design for bone tissue engineering application. The materials were prepared from high deacetylation degree chitosan. The authors describe the method for scaffold fabrication, essential properties of the materials manufactured and the influence of various TCP concentrations on material morphology, mechanical properties (for dry and hydrated materials) and preliminary study on the interaction between CH or CH/TCP scaffolds and within cultured MG-63 osteoblast-like cells. The properties of the obtained materials were significantly affected by the calcium phosphate content, which had a particular influence on the granule microstructure, size distribution and inner biomaterial pore size. The water uptake ability was found to be lower for the materials enriched with the inorganic phase and tended to decrease with the increasing calcium phosphate concentration. The evaluation of mechanical properties has revealed that scaffolds produced with the usage of granule-based technology display a potential to be used as a load-bearing material since the Young’s modulus values were limited to the range of 200–500 MPa for dry materials and 15–20 MPa for the hydrated state of the scaffolds. The cell number, identified in three time points (48 h, 7 and 14 days) by Pico Green assay, was lower for the materials enriched with inorganic phase (75 % of control), however cell distribution, when compared to CH only biomaterial, was acknowledged as steadier on the surface of the material containing the highest calcium phosphate concentration.

Similar content being viewed by others

References

Gasser B. About composite materials and their use in bone surgery. Injury. 2000;31:S-D48-53.

Peter M, Ganesh N, Selvamurugan N, Nair SV, Furuike T, Tamura H, Jayakumar R. Preparation and characterization of chitosan-gelatin/nanohydroxyapatite composite scaffolds for tissue engineering applications. Carbohydr Polym. 2010;80(3):687–94.

Khor E, Lim LY. Implantable applications of chitin and chitosan. Biomaterials. 2003;24(13):2339–49.

Muzzarelli RAA. Chitosan composites with inorganics, morphogenetic proteins and stem cells, for bone regeneration. Carbohydr Polym. 2011;83:1433–45.

Ravi Kumar MNV, Muzzarelli RAA, Muzzarelli C, Sashiwa H, Domb AJ. Chitosan chemistry and pharmaceutical perspectives. Chem Rev. 2004;104(12):6017–84.

Hsieh CY, Tsai SP, Ho MH, Wang DM, Liu CE, Hsieh CH, Tseng HC, Hsieh HJ. Analysis of freeze-gelation and cross-linking processes for preparing porous chitosan scaffolds. Carbohydr Polym. 2007;67:124–32.

Lu S, Gao W, Gu HY. Construction, application and biosafety of silver nanocrystalline chitosan wound dressing. Burns. 2008;34:623–8.

Borchard G. Chitosans for gene delivery. Adv Drug Deliv Rev. 2001;52(8):145–50.

Chen JP, Chang GY, Chan JK. Electrospun collagen/chitosan nanofibrous membrane as wound dressing. Colloids Surf A. 2008;313–314:183–8.

Mi FL, Shyu SS, Wu YB, Lee ST, Shyong JY, Huang RN. Fabrication and characterization of a sponge-like asymmetric chitosan membrane as a wound dressing. Biomaterials. 2001;22:165–73.

Yang ZH, Sato T, Koyama Y. Development of chitosan nanoparticles for gene delivery system. Mol Ther. 2006;13(7):S76–7.

Kim IY, Seo SJ, Moon HS, Yoo MK, Park IY, Kim BC, Cho CS. Chitosan and its derivatives for tissue engineering applications. Biotechnol Adv. 2008;26(1):1–21.

Seol YJ, Lee JY, Park YJ, Lee YM, Ku Y, Rhyu IC, Lee SJ. Chitosan sponges as tissue engineering scaffolds for bone formation. Biotechnol Lett. 2004;26:1037–41.

Yang B, Li XY, Shi S, Kong XY, Guo G, Huang MJ, Luo F, Wei YQ, Zhao X, Qian ZY. Preparation and characterization of a novel chitosan scaffold. Carbohydr Polym. 2010;80(3):860–5.

Zhao L, Chang J. Preparation and characterization of macroporous chitosan/wollastonite composite scaffolds for tissue engineering. J Mater Sci. 2004;15:625–9.

Jiang T, Abdel-Fattah WI, Laurencin CT. In vitro evaluation of chitosan/poly(lactic acid-glycolic acid) sintered microsphere scaffolds for bone tissue engineering. Biomaterials. 2006;27(28):4894–903.

Kumbar SG, Toti US, Deng M, James R, Laurencin CT, Aravamudhan A, Marmon M, Ramos DM. Novel mechanically competent polysaccharide scaffolds for bone tissue engineering. Biomed Mater. 2011;6(6):065005.

Champion E. Sintering of calcium phosphate bioceramics. Acta Biomater. 2013;9:5855–75.

Giannoudis PV, Dinopoulos H, Tsiridis E. Bone substitutes: an update. Injury Int J Care Injured. 2005;365:520–7.

Lichte P, Pape HC, Pufe T, Kobbe P, Fischer H. Scaffolds for bone healing: concepts, materials and evidence. Injury. 2011;42:569–73.

Lobo SE, Arinzeh TL. Biphasic calcium phosphate ceramics for bone regeneration and tissue engineering applications. Materials. 2010;3:815–26.

Kucharska M, Walenko K, Butruk B, Brynk T, Heljak M, Ciach T. Fabrication and characterization of chitosan microspheres agglomerated scaffolds for bone tissue engineering. Mater Lett. 2010;64(9):1059–62.

Hsu S, Whu SW, Tsai CL, Wu YH, Chen HW, Hsieh KH. Chitosan as scaffold materials: effects of molecular weight and degree of deacetylation. J Polym Res. 2004;11(2):141–7.

Nettles DL, Elder SH, Gilbert JA. Potential use of chitosan as a cell scaffold material for cartilage tissue engineering. Tissue Eng. 2002;8(6):1009–16.

SedaTığlı R, Karakeçili A, Gümüşderelioğlu M. In vitro characterization of chitosan scaffolds: influence of composition and deacetylation degree. J Mater Sci. 2007;18:1665–74.

Ren D, Yi H, Wang W, Ma X. The enzymatic degradation and swelling properties of chitosan matrices with different degrees of N-acetylation. Carbohydr Res. 2005;340:2403–10.

Zan Q, Wang C, Cheng P, Tian J. Effect of surface roughness of chitosan-based microspheres on cell adhesion. Appl Surf Sci. 2008;255:401–3.

Montanaro L, Arciola CR, Campoccia D, Cervellati M. In vitro effects on MG63 osteoblast-like cells following contact with two roughness-differing fluorohydroksyapatite-coated titanium alloys. Biomaterials. 2002;23:3651–9.

Goldstein SA. The mechanical properties of trabecular bone: dependence on anatomic location and function. J Biomech. 1987;20(11–12):1055–61.

Thein-Han WW, Misra RDK. Biomimetic chitosan-nanohydroxyapatite composite scaffolds for bone tissue engineering. Acta Biomater. 2009;5:1182–97.

Karageorgiou V, Kaplan D. Porosity of 3D biomaterial scaffolds and osteogenesis. Biomaterials. 2005;26:5474–91.

Acknowledgments

This work has been supported by the European Union in the framework of European Social Fund through the Warsaw University of Technology Development Programme1# and Grant No. NR 13-0008-10/2010 from The National Centre for Research and Development.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kucharska, M., Walenko, K., Lewandowska-Szumieł, M. et al. Chitosan and composite microsphere-based scaffold for bone tissue engineering: evaluation of tricalcium phosphate content influence on physical and biological properties. J Mater Sci: Mater Med 26, 143 (2015). https://doi.org/10.1007/s10856-015-5464-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10856-015-5464-9