Abstract

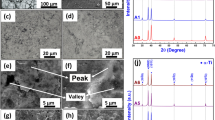

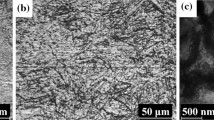

The combination of shot blasting (SB) and micro-arc oxidation (or anodic oxidation—AO) in titanium surfaces was shown to provide enhanced conditions for cell differentiation and osseointegration than those provided by SB or AO alone. This study associated both methods aiming to attain titania layers on Ti with adequate tribo-mechanical features for bone implants. SB was performed using alumina particles, and titania layers were grown by AO using a CaP-based electrolyte. Mechanical properties and scratch resistance were characterized at nanoscale by instrumented indentation and nanoscratch, and correlated with morphological and microstructural changes (XRD, SEM, EDS, AFM, and profilometry). Analytical methods were employed to correct roughness and substrate effects on the indentation results. CaP-containing TiO2 layers were produced on AO and SB + AO. The latter presented small pore size and inhomogeneous layer thickness and Ca/P ratios, caused by the non-uniform surface straining by SB that affects the oxide growth kinetics in the electrochemical process. Elastic modulus of SB + AO layer (37 GPa) were lower than the AO one (45 GPa); both of them were smaller than bulk Ti (130 GPa) and close to bone values. The hardness profiles of AO and SB + AO were similar to the substrate ones. Because of the improved load bearing capacity and unique layer features, the critical load to remove the SB + AO titania coating in scratch tests was three times as much or higher than in AO. Results indicate improved mechanical biocompatibility and tribological strength of anodic titania layers grown on sand blasted Ti surfaces.

Similar content being viewed by others

References

Liu X, Chu P, Ding C. Surface modification of titanium, titanium alloys, and related materials for biomedical applications. Mater. Sci. Eng. R. 2004;47:49–121.

Geetha M, Singh AK, Asokamani R, Gogia AK. Ti based biomaterials, the ultimate choice for orthopaedic implants—a review. Prog Mater Sci. 2009;54:397–425.

Liu X, Chu PK, Ding C. Surface nano-functionalization of biomaterials. Mater. Sci. Eng. R. 2010;70:275–302.

Takemoto M, Fujibayashi S, Neo M, Suzuki J, Matsushita T, Kokubo T, et al. Osteoinductive porous titanium implants: effect of sodium removal by dilute HCl treatment. Biomaterials. 2006;27:2682–91.

Le Guéhennec L, Soueidan A, Layrolle P, Amouriq Y. Surface treatments of titanium dental implants for rapid osseointegration. Dent Mater. 2007;23:844–54.

Elias CN, Oshida Y, Lima JHC, Muller CA. Relationship between surface properties (roughness, wettability and morphology) of titanium and dental implant removal torque. J Mech Behav Biomed Mater. 2008;1:234–42.

Oliveira NCM, Moura CCG, Zanetta-Barbosa D, Mendonça DBS, Cooper L, Mendonça G, et al. Effects of titanium surface anodization with CaP incorporation on human osteoblastic response. Mater Sci Eng C. 2013;33:1958–62.

Aparicio C, Gil FJ, Fonseca C, Barbosa M, Planell JA. Corrosion behaviour of commercially pure titanium shot blasted with different materials and sizes of shot particles for dental implant applications. Biomaterials. 2003;24:263–73.

Naji A, Harmand MF. Cytocompatibility of two coating materials, amorphous alumina and silicon carbide, using human differentiated cell cultures. Biomaterials. 1991;12:690–4.

Szesz EM, Pereira BL, Kuromoto NK, Marino CEB, de Souza GB, Soares P. Electrochemical and morphological analyses on the titanium surface modified by shot blasting and anodic oxidation processes. Thin Solid Films. 2013;528:163–6.

Sul YT, Johansson CB, Jeong Y, Ro K, Wennerberg A, Albrektsson T. Oxidized implants and their influence on the bone response. J Mater Sci Mater Med. 2001;12:1025–31.

Yang B, Uchida M, Kim H-M, Zhang X, Kokubo T. Preparation of bioactive titanium metal via anodic oxidation treatment. Biomaterials. 2004;25:1003–10.

El-Wassefy NA, Hammouda IM, Habib ANEA, El-Awady GY, Marzook HA. Assessment of anodized titanium implants bioactivity. Clin Oral Implants Res. 2012;25:1–9.

Niinomi M. Mechanical biocompatibilities of titanium alloys for biomedical applications. J Mech Behav Biomed Mater. 2008;1:30–42.

Soares P, Mikowski A, Lepienski CM, Santos E, Soares A. Hardness and elastic modulus of TiO2 anodic films measured by instrumented indentation. J Biomed Mater Res B. 2008;84:524–30.

De Souza GB, de Lima GG, Kuromoto NK, Soares P, Lepienski CM, Foerster CE, et al. Tribo-mechanical characterization of rough, porous and bioactive Ti anodic layers. J Mech Behav Biomed Mater. 2011;4:796–806.

Szesz EM, de Souza GB, Santos E, Kuromoto NK. Nanomechanical properties of bioactive ti surfaces obtained by NaOH-based anodic oxidation and alkali treatment. Key Eng Mater. 2011;493–494:524–9.

Korkusuz P, Korkusuz F. Hard tissue-biomaterial interactions. In: Yaszemski MJ, et al., editors. Biomaterials in Orthopaedics. New York: Marcel Dekker; 2004.

Deng F, Zhang W, Zhang P, Liu C, Ling J. Improvement in the morphology of micro-arc oxidised titanium surfaces: a new process to increase osteoblast response. Mater Sci Eng C. 2010;30:141–7.

Saha R, Nix WD. Effects of the substrate on the determination of thin film mechanical properties by nanoindentation. Acta Mater. 2002;50:23–38.

Oliver WC, Pharr GM. Measurement of hardness and elastic modulus by instrumented indentation: advances in understanding and refinements to methodology. J Mater Res. 2004;19:3–20.

De Souza GB, Mikowski A, Lepienski CM, Foerster CE. Indentation hardness of rough surfaces produced by plasma-based ion implantation processes. Surf Coat Technol. 2010;204:3013–7.

Xu H, Pharr GM. An improved relation for the effective elastic compliance of a film/substrate system during indentation by a flat cylindrical punch. Scr Mater. 2006;55:315–8.

Meyers MA, Chawla KK. Mechanical behavior of materials. New Jersey: Prentice Hall; 1999.

Borgese L, Gelfi M, Bontempi E, Goudeau P, Geandier G, Thiaudière D, et al. Young modulus and Poisson ratio measurements of TiO2 thin films deposited with atomic layer deposition. Surf Coat Technol. 2012;206:2459–63.

Hu T, Xin YC, Wu SL, Chu CL, Lu J, Guan L, et al. Corrosion behavior on orthopedic NiTi alloy with nanocrystalline/amorphous surface. Mater Chem Phys. 2011;126:102–7.

Cullity BD, Stock SR. Elements of X-ray diffraction. Upper Saddle River: Prentice Hall; 2001.

De Souza GB, Foerster CE, Lepienski CM, Kuromoto NK, da Silva SLR, Schreiner WH. Structural, chemical and tribo-mechanical surface features of Ti and nitrided Ti submitted to hydrogen low energy implantation. Mater Chem Phys. 2010;124:443–52.

Chen J, Shi Y, Wang L, Yan F, Zhang F. Preparation and properties of hydroxyapatite-containing titania coating by micro-arc oxidation. Mater Lett. 2006;60:2538–43.

Liu F, Song Y, Wang F, Shimizu T, Igarashi K, Zhao L. Formation characterization of hydroxyapatite on titanium by microarc oxidation and hydrothermal treatment. J Biosci Bioeng. 2005;100:100–4.

Simka W, Iwaniak A, Nawrat G, Maciej A, Michalska J, Radwański K, et al. Modification of titanium oxide layer by calcium and phosphorus. Electrochim Acta. 2009;54:6983–8.

Kokubo T, Matsushita T, Takadama H. Titania-based bioactive materials. J Eur Ceram Soc. 2007;27:1553–8.

Novaes AB, de Souza SLS, de Barros RRM, Pereira KKY, Iezzi G, Piattelli A. Influence of implant surfaces on osseointegration. Braz Dent J. 2010;21:471–81.

Perrin D, Szmukler-Moncler S, Echikou C, Pointaire P, Bernard J-P. Bone response to alteration of surface topography and surface composition of sandblasted and acid etched (SLA) implants. Clin Oral Implants Res. 2002;13:465–9.

Braceras I, Alava JI, Goikoetxea L, de Maeztu MA, Onate JI. Interaction of engineered surfaces with the living world: Ion implantation vs. osseointegration. Surf Coat Technol. 2007;201:8091–8.

Li L-H, Kong Y-M, Kim H-W, Kim Y-W, Kim H-E, Heo S-J, et al. Improved biological performance of Ti implants due to surface modification by micro-arc oxidation. Biomaterials. 2004;25:2867–75.

Tsui TY, Pharr GM. Substrate effects on nanoindentation mechanical property measurement of soft films on hard substrates. J Mater Res. 2012;14:292–301.

Choi J, Wehrspohn RB, Lee J, Gösele U. Anodization of nanoimprinted titanium: a comparison with formation of porous alumina. Electrochim Acta. 2004;49:2645–52.

Jackson MJ, Ahmed W. Anodization: A promising nano-modification technique of titanium-based implants for orthopedic applications. In: Surface engineered surgical tools and medical devices. New York: Springer; 2007. p. 21–47.

Gao H, Chiu C-H, Lee J. Elastic contact versus indentation modeling of multi-layered materials. Int J Solids Struct. 1992;29:2471–92.

Diebold U. The surface science of titanium dioxide. Surf Sci Rep. 2003;48:53–229.

Acknowledgments

We are grateful to the Institutional Laboratories C-LABMU/UEPG and CME/UFPR, the Neoortho Company for the shot blasting treatments, and the Brazilian funding agencies CNPq and Fundação Araucária.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Szesz, E.M., de Souza, G.B., de Lima, G.G. et al. Improved tribo-mechanical behavior of CaP-containing TiO2 layers produced on titanium by shot blasting and micro-arc oxidation. J Mater Sci: Mater Med 25, 2265–2275 (2014). https://doi.org/10.1007/s10856-014-5238-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10856-014-5238-9