Abstract

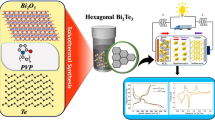

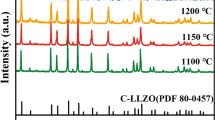

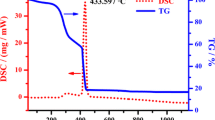

The volatilization of bismuth (Bi) species and bismuth oxide (Bi2O3) leads to the presence of the oxygen vacancies (V 00O ) and consequently restrains the properties of bismuth titanate (BIT; Bi4Ti3O12). This report presents the incorporation of different atomic ratios of praseodymium ion (Pr3+: x = 0, 0.2, 0.4, 0.6, 0.8 and 1.0) into the BIT (Bi4−x Pr x Ti3O12) ceramics through an intermediate fuel agent-assisted self-combustion synthesis (IFSC). X-ray diffraction and Raman spectroscopy results revealed that some of bismuth ion (Bi3+) in the pseudo-perovskite layer containing Ti–O octahedra was substituted by Pr3+ ion. The substitution by ion with a smaller ionic radius caused the structure distortion and consequently resulted in the phase transformation from an orthorhombic symmetry to a tetragonal symmetry. Besides, it suppressed the volatilization of Bi and Bi2O3 and increased the stability of metal–oxygen octahedra in the BIT. These play a crucial role to control the crystal growth, as well as limit the V 00O . Dense ceramic with a relative density up to 96.2% was obtained by incorporating Pr3+ with atomic ratio of 1.0. It exhibited high dielectric constant as 908.19 and low dissipation factor as 0.0011. The results address the possibility to control the structure, morphology and dielectric properties of BIT ceramic by incorporating Pr3+ ion through IFSC.

Similar content being viewed by others

References

Yueming L, Wen C, Qing X, Jing Z (2007) Ceram Int 33:95

Hyatt NC, Hriljac JA, Comyn TP (2003) Mater Res Bull 38:837

Subbarao EC (1961) Phys Rev 122:804

Hou J, Kumar RV, Qu Y, Krsmanovic D (2009) J Nanopart Res 12:563

Villegas M, Jardiel T, Caballero AC (2009) J Eur Ceram Soc 29:737

Lazarevic ZZ, Romcevic NZ, Bobic JD, Romcevic MJ, Dohcevic-Mitrovic Z, Stojanvic BD (2009) J Alloys Compd 486:848

Lazarevic ZZ, Stojanvic BD, Paiva-Santos CO, Romcevic NZ (2008) Ferroelectric 368:154

Tang Q-Y, Kan Y-M, Li Y-G, Zhang G-J, Wang P-L (2006) Sci Mater 54:2075

Simoes AZ, Quinelato C, Ries A, Stojanovic BD, Longo E, Varela JA (2006) Mater Chem Phys 98:481

Takahashi M, Noguchi Y, Miyayama M (2005) J Ceram Process Res 6:281

Yoneda Y, Kohara S, Mizuki J (2006) J Appl Phys 45:7556

Park BH, Kang BS, Bu SD, Noh TW, Lee J, Jo W (1999) Nature 401:682

Yamada M, Iizawa N, Yamaguchi T, Sakamoto W, Kikuta K, Yogo T, Hayashi T, Hirano S-I (2003) Jpn J Appl Phys 42:5222

Cheng CP, Tang MH, Ye Z, Zhong XL, Zheng XJ, Zhou YC, Hu ZS (2007) Mater Lett 61:3563

Chen Y-C (2006) Thin Solid Films 513:331

Kim JK, Kim J, Song TW, Kim SS (2002) Thin Solid Films 419:225

Goh PY, Razak KA, Sreekantan S (2009) J Alloys Compd 475:758

Krengvirat W, Sreekantan S, Ahmad-Fauzi MN, Matsuda A, Chinwanitcharoen C (2012) J Ceram Soc Jpn 120:1

Achary SN, Patwe SJ, Krishna PSR, Shinde AB, Tyagi AK (2008) J Phys 71:935

Kim JS, Lee SY, Lee HJ, Ahn CW, Kim WI, Jang MS (2008) J Electroceram 21:633

Simoes AZ, Stojanovic BD, Ramirez MA, Cavalheiro AA, Longo E, Varela JA (2008) Ceram Int 34:257

Moore JJ, Yi HC (1990) J Mater Sci 25:1159. doi:10.1007/BF00585421

Du X, Xu Y, Ma H, Wang J, Li X (2007) J Am Ceram Soc 90:1382

Wang X-H, Chen R-Z, Gui Z-L, Li LT (2003) Mater Sci Eng B 99:199

Wang YH, Huang CP, Zhu YY (2006) Solid State Commun 138:229

Du YL, Zhang MS, Chen Q, Yuan ZR, Yin V, Zhang QA (2002) Solid State Commun 124:113

Wang Y, Xu G, Zhang X, Tang W, Cheng G, Zhu Y (2004) Mater Lett 58:813

Oliveira RC, Cavalcante LS, Sczancoski JC, Aguiar EC, Espinosa JWM, Varela JA, Pizani PS, Longo E (2009) J Alloys Compd 478:661

Luo S, Tang Z, Yao W, Zhang Z (2003) Microelectron Eng 66:147

Ng CY, Razak KA (2011) J Alloys Compd 509:942

Razak KA, Cheah JY, Sreekantan S (2011) J Alloys Compd 509:2936

Krengvirat W, Sreekantan S, Ahmad-Fauzi MN, Chinwanitcharoen C, Hiroyuki M, Atsunori M (2011) J Ceram Int. doi:10.1016/j.ceramint.2011.11.081

Hervoches CH, Lightfoot P (1991) Chem Mater 11:3359

Zarycka A, Lisinska-Czekaj A, Czuber J, Orkisz T, Ilczuk J, Czekaj D (2005) Mater Sci-Pol 23:167

Graves PR, Hua G, Myhra S, Thompson JG (1995) J Solid State Chem 114:112

Ling ZC, Xia HR, Liu WL, Han H, Wang XQ, Sun SQ, Ran DG, Yu LL (2006) Mater Sci Eng B 128:156

Zhou D, Gu H, Hu Y, Qian Z, Hu Z, Yang K, Zou T, Wang Z, Guan J, Chen W (2010) J Appl Phys 107:094105-1, 094105-3–094105-6

Watcharapasorn A, Siriprapa P, Jiansirisomboon S (2009) J Eur Ceram Soc 30:87

Chon U, Shim JS (2003) J Appl Phys 93:4769

Buessem WR, Cross LE, Goswami AK (1996) J Am Ceram Soc 49:33

Arlt G (1989) Ferroelectrics 91:3

Kong LB, Ma J, Zhu W, Tan OK (2001) Mater Lett 51:108

Coondoo I, Jha AK, Agarwal SK (2007) Ceram Int 33:41

Simoes AZ, Pianno RF, Riccardi CS, Cavalcante LS, Longo E, Varela JA (2008) Ceram Int 454:66

Takahashi M, Noguchi Y, Miyayama M (2005) Ceram Process Res 6:281

Gachigi KW, Kumar U, Dougherty JP (2002) ISAF ‘92, Proc Eighth IEEE Int Symp Appl 492–495

Acknowledgements

The authors like to thank Universiti Sains Malaysia for sponsoring this work under a 2008 short-term grant (6035276) and the ASEAN University Network for Science and Engineering Education (AUN/SEED-net) (6050151).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Krengvirat, W., Sreekantan, S., Ahmad-Fauzi, M.N. et al. Control of the structure, morphology and dielectric properties of bismuth titanate ceramics by praseodymium substitution using an intermediate fuel agent-assisted self-combustion synthesis. J Mater Sci 47, 4019–4027 (2012). https://doi.org/10.1007/s10853-012-6255-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-012-6255-z