Abstract

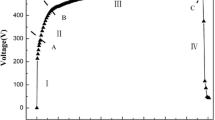

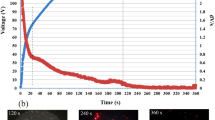

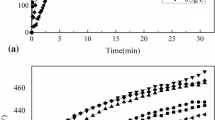

This study presents a new approach to enhance the corrosion resistance of tungsten inert gas (TIG) welded AZ31 magnesium alloys by using nanocrystalline magnesium fluoride suspensions in a suspension plasma spray (SPS) process. We have developed a synthesis for the preparation of nanocrystalline magnesium fluoride suspensions, which delivers nearly monodisperse nanoparticles in a gram scale yield. The particles were analyzed with transmission electron microscopy (TEM) and powder X-ray diffraction (PXRD). Stable suspensions of magnesium fluoride nanoparticles in water were characterized by dynamic light scattering (DLS), zeta-potential, and viscosity measurements. Such suspensions were deposited with an SPS torch onto TIG welded seams of the magnesium alloy AZ31, thus producing a protective magnesium fluoride layer. Magnesium fluoride covered welded seams were investigated by scanning electron microscopy (SEM), X-ray diffraction (XRD), and energy dispersive X-ray spectroscopy (EDXS). In order to introduce a simple method for sensoring the deposited magnesium fluoride coatings, the magnesium fluoride nanoparticles can also be fluorescence-labeled by co-doping with cerium(III) and terbium(III), the respective optical properties were characterized by reflection and luminescence spectroscopy. The deposited layers can, thus, be inspected by illumination with an UV lamp, because of their bright green emission. The corrosion properties of the magnesium fluoride layer on the welded seams were studied by means of potentiodynamic potential measurements.

Similar content being viewed by others

References

Makar GL, Kruger J (1993) Int Mater Rev 38:3

Song G (2005) Adv Eng Mater 7(7):563

Gray JE, Luan B (2002) J Alloys Compd 336:88

Ghali E, Dietzel W, Kainer K-U (2004) J Mater Eng Perform 13:7

Song G, Atrens A (2003) Adv Eng Mater doi:10.1002/adem.200310405

Song G, Atrens A (1999) Adv Eng Mater 1:11

Thate W, Zschetzsche J (2003) wt Werkstattstechnik online 10:699

Xu RZ, Song G, Wang Z (2009) Mater Res Innov 13:441

Zeng R-C, Chen J, Dietzel W, Zettler R, dos Santos JF, Nascimento ML, Kainer KU (2009) Corros Sci 51:1738

Kurze P (1998) Mat-wiss Werkstofftech 29:85

Yerokhin AL, Shatrov A, Samsonov V, Shashkov P, Leyland A, Matthews A (2004) Surf Coat Technol. doi:10.1016/S0257-8972(03)00877-6

Blawert C, Hort N, Kainer KU (2004) Trans Indian Inst Met 57:397

Witte F, Fischer J, Nellesen J, Vogt C, Vogt J, Donath T, Beckmann F (2009) Acta Biomater. doi:10.1016/j.actbio.2009.10.012

Alvarez-Lopez M, Pereda MD, del Valle JA, Fernandez-Lorenzo M, Garcia-Alonso MC, Ruano OA, Escudero ML (2009) Acta Biomater. doi:10.1016/j.actbio.2009.04.041

Chiu KY, Wong MH, Cheng FT, Man HC (2007) Surf Coat Technol 202:590

Brar HS, Platt MO, Sarntinoranont M, Martin PI, Manuel M (2009) J Miner Met Mater Soc. doi:10.1007/s11837-009-0129-0

Krause A, von der Höh D, Bormann D, Krause C, Bach F-W, Windhagen H, Meyer-Lindenberg A (2010) J Mater Sci. doi:10.1007/s10853-009-3936-3

Li JN, Cao P, Zhang XN, Zhang SX, He YH (2010) J Mater Sci. doi:10.1007/s10853-010-4688-9

Li Y, Hodgson PD, Wen C (2011) J Mater Sci. doi:10.1007/s10853-010-4843-3

Bach Fr-W, Hassel T, Krause C, Wilk P (2005) In: Neelamagghan NR, Kaplan HI, Powell BR (eds) Magnesium technology 2005. TMS, Warrendale

Lellouche J, Kahana E, Elias S, Gedanken A, Banin E (2009) Biomater 30:5969

Toma F-L, Berger L-M, Naumann T, Langer S (2008) Surf Coat Technol 202:4343

Pawlowski L (2009) Surf Coat Technol 203:2807

Kozerski S, Pawlowski L, Jaworski R, Roudet F, Petit F (2009) Surf Coat Technol. doi:10.1016/j.surfcoat.2009.09.020

Chen Z, Trice RW, Besser M, Yang X, Sordelet D (2004) J Mater Sci 39:4171

Burlacov I, Jirkovsky J, Müller M, Heinmann RB (2006) Surf Coat Technol 201:255

Tomaszek R, Pawlowski L, Gengembre L, Laureyns J, Znamirowski Z, Zdanowski J (2006) Surf Coat Technol 201:45

Wittmann-Teneze K, Valle K, Bianchi L, Belleville P, Caron N (2008) Surf Coat Technol 202:4349

Jaworski R, Pawlowski L, Pierlot C (2009) Thermal Spray. doi: 10.1361/cp2009itsc0156

Feldmann C (2005) Solid State Sci 7:868

Feldmann C, Roming M, Trampert K (2006) Small 2:1248

Eiden-Assmann S, Maret G (2004) Mater Res Bull 39:21

Wei Y, Lu F, Zhang X, Chen D (2007) Mater Lett 61:1337

Wang ZL, Quan ZW, Jia PY, Lin CK, Luo Y, Chen Y, Fang J, Zhou W, O’Connor CJ, Lin J (2006) Chem Mater. doi:10.1021/cm052360x

Kong D, Wang ZL, Lin CK, Quan ZW, Li YY, Li CX, Lin J (2007) Nanotechnology. doi:10.1088/0957-4484/18/7/075601

Kuznetsov S, Osiko V, Tkatchenko E, Fedorov P (2006) Russ Chem Rev 75:1065

Riwotzki K, Meyssamy H, Schnablegger H, Kornowski A, Haase M (2001) Angew Chem Int Ed 113:574

Heinroth F, Gruss D, Müller S, Waltz F, Martynczuk J, Feldhoff A, Behrens P, Wiebcke M (2009) J Mater Sci. doi:10.1007/s10853-009-4130-3

Heinroth F, Waltz F, Wiebcke M, Behrens P (2008) Z Anorg Allg Chem. doi:10.1002/zaac.200870073

Sokolnicki J (2010) J Phys : Condens Mater doi:10.1088/0953-8984/22/27/275301

Zanetti-Ramos BG, Fritzen-Garcia MB, Creczynski-Pasa TB, De Oliveira CS, Pasa AA, Soldi V, Borsali R (2010) Part Sci Technol. doi:10.1080/02726351.2010.504133

Tseng WJ, Lin K-C (2002) Mater Sci Eng A. doi:10.1016/S0921-5093(03)00063-7

Kong D, Yang H, Yang Y, Wei S, Wang J, Cheng B (2004) Mater Lett. doi:10.1016/j.matlet.2004.06.060

Witte F, Fischer J, Nellesen J, Crostack H-A, Kaese V, Pisch A, Beckmann F, Windhagen H (2006) Biomaterials. doi:10.1016/j.biomaterials.2005.07.037

Shi Z, Liu M, Atrens A (2009) Corros Sci. doi:10.1016/j.corsci.2009.10.016

Song G, Atrens A, Dargusch M (1999) Corros Sci. doi:10.1016/S00-10-938X(98)00121-8

Acknowledgements

We gratefully acknowledge the financial support of the Volkswagen foundation via the research initiative “Innovative Methods for Manufacturing Multifunctional Surfaces”.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Waltz, F., Swider, M.A., Hoyer, P. et al. Synthesis of highly stable magnesium fluoride suspensions and their application in the corrosion protection of a Magnesium alloy. J Mater Sci 47, 176–183 (2012). https://doi.org/10.1007/s10853-011-5785-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-011-5785-0