Abstract

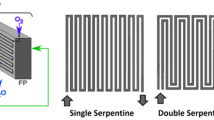

Mass production of hydrogen is a major issue for the coming decades particularly to decrease greenhouse gas production. The development of fourth-generation high-temperature nuclear reactors has led to renewed interest for hydrogen production. In France, the CEA is investigating new processes using nuclear reactors, such as the Westinghouse hybrid cycle. A recent study was devoted to electrical modeling of the hydrogen electrolyzer, which is the key unit of this process. In this electrochemical reactor, hydrogen is reduced at the cathode and SO2 is oxidized at the anode with the advantage of a very low voltage cell. This paper describes an improved model coupling the electrical and thermal phenomena with hydrodynamics in the electrolyzer, designed for a priori computational optimization of our future pilot cell. The hydrogen electrolyzer chosen here is a filter press design comprising a stack of identical cathode and anode compartments separated by a membrane. In a complex reactor of this type the main coupled physical phenomena involved are forced convection of the electrolyte flows, the plume of evolving hydrogen bubbles that modifies the local electrolyte conductivity, and all the irreversible processes that contribute to local overheating (Joule effect, overpotentials, etc.). The secondary current distribution was modeled with a commercial FEM code, Flux Expert®, which was customized with specific finite interfacial elements capable of describing the potential discontinuity associated with the electrochemical overpotential. Since the finite element method is not capable of properly describing the complex two-phase flows in the cathode compartment, the Fluent® CFD code was used for thermohydraulic computations. In this way each physical phenomenon was modeled using the best numerical method. The coupling implements an iterative process in which each code computes the physical data it has to transmit to the other one: the two-phase thermohydraulic problem is solved by Fluent® using the Flux-Expert® current density and heat sources; the secondary distribution and heat losses are solved by Flux-Expert® using the Fluent® temperature field and flow velocities. A set of dedicated library routines was developed for process initiation, message passing, and synchronization of the two codes. The first results obtained with the two coupled commercial codes give realistic distributions for the electrical current density, gas fraction, and velocity in the electrolyzer. This approach allows us to optimize the design of a future experimental device.

Similar content being viewed by others

Abbreviations

- Cp :

-

Heat capacity (J kg−1 K−1)

- \( \ifmmode\expandafter\vec\else\expandafter\vec\fi{g} \) :

-

Gravitational acceleration (m s−2)

- \( \ifmmode\expandafter\vec\else\expandafter\vec\fi{J} \) :

-

Current density (A m−2)

- j n :

-

Current density normal to the interface (A m−2)

- k :

-

Thermal conductivity (W m−1 K−1)

- \( \ifmmode\expandafter\vec\else\expandafter\vec\fi{n} \) :

-

Normal vector

- NBN:

-

Number of integration points

- Q S :

-

Surface heat sources (W m−2)

- Q V :

-

Volume heat sources (W m−3)

- T :

-

Temperature (K)

- t :

-

Time (s)

- \( \ifmmode\expandafter\vec\else\expandafter\vec\fi{u} \) :

-

Velocity vector (m s−1)

- u, v :

-

Relative coordinates

- V :

-

Electrical scalar potential (V)

- α(u, v), γ, β:

-

Lagrange polynomials

- δ:

-

Nanometric discontinuity thickness of potential (m)

- δ S :

-

Dirac surface distribution

- εg :

-

Gas fraction

- ρ:

-

Density (kg m−3)

- η:

-

Overpotential (V)

- \( \overline{\overline \sigma }\) :

-

Viscous stress tensor (Pa)

- σ:

-

Electrical conductivity (Ω−1 m−1)

- \( \ifmmode\expandafter\vec\else\expandafter\vec\fi{\nabla } \) :

-

Nabla vector differential operator \( (\partial _{x} \bullet ,\partial _{y} \bullet ,\partial _{z} \bullet) \)

References

Gauthier JC, Brinkmann G, Copsey B, Lecomte M (2006) Nucl Eng Des 236:526–533

Vitart X, Le Duigou A, Carles P (2006) Energy Conversion Manag 47:2740–2747

Brecher LE, Wu CK (1975) US Patent No 3,888,750 assigned to Westinghouse Electric Corporation

Brecher LE, Spewock S, Warde CJ (1977) Int J Hydrogen Energy 2:7–15

Agranat S, Zhubrin AM, Hinatsu J, Stemp M, Kawaji M (2006) European fluids engineering summer meeting July, Proceedings of FEDSM 2006 ASME Joint U.S., Miami, FL, pp 17–20

Jomard F, Feraud JP, Morandini J, Du Terrail Couvat Y, Caire JP (2007) Modeling a filter press electrolyzer for the Westinghouse hybrid cycle using two coupled codes, International Conference on Nuclear Engineering, Nagoya, Japan, Proceeding ICONE15-10639

Goosen JE, Lahoda EJ, Matzie R, Mazzoccoli JP (2003) Improvements in Westinghouse process for hydrogen production, pp. 1509–1513

Roustan H, Caire JP, Nicolas F, Pham P (1998) J Appl Electrochem 28:237–243

Struck BD, Junginger R, Boltersdorf D, Gehrmann J (1980) Int J Hydrogen Energy 5:487–497

Lu PWT, Ammon RL (1980) J Electrochem Soc 127(12):2610–2616

Coeuret F, Storck A (1993) Eléments de génie électrochimique, Technique & Documentation, Lavoisier, Paris

Hwang JJ, Wu SD, Lai LK, Chen CK, Lai DY (2006) J Power Sources 161:240–249

Jomard F, DRT (2002) Prédimensionnement par modélisation numérique de l’électrolyseur de production d’hydrogène du cycle hybride Westinghouse, INPG, Grenoble

Atey BG, El Shakre ME (1983) J Appl Electrochem 14(3):367–371

Wetind R (2001) Ph.D. Thesis, Royal Institute of technology, Two-phase flows in gas-evolving electrochemical applications Stockholm

Shih TH, Liou WW, Shabbir A, Yang Z, Zhu J (1995) A new k–ε eddy-viscosity model for high Reynolds number turbulent flows, model development and validation. Comput Fluids 24(3):227–238

Arnaud P (1988) Cours de chimie physique. Dunod, Paris

Vogt H (1999) J Appl Electrochem 29(10):1155–1159

Vogt H (1997) Electrochimica Acta 42(17):2695–2705

Vogt H (1999) J Appl Electrochem 29(10):137–145

Caire JP, Chifflet H (2002) Environmetrics 13(1):1–8

Eigeldinger J, Vogt H (2000) Electrochimica Acta 45(27):4449–4456

Clift R, Grace JR, Weber ME (1978) Bubbles, drops and particles. Academic Press, NY

Espinasse G, Peyrard M, Nicolas F, Caire JP (2007) J Appl Electrochem 37:77–85

Mandin P, Wüthrich R, Hamburger J, Picard G, Diphasic (2005) Electrolysis process modelling for a vertical electrode. Proceedings of the 7th European symposium on electrochemical engineering, Toulouse, France

Nougier JP (1991) Méthodes de calcul numérique, 3e edn. MASSON, Paris

Fluent (2005) Users manual, chapter 24

Caire JP, Roure A (2007) Pre design of a molten salt thorium reactor loop. 15th International conference on nuclear engineering, Nagoya, Japan, Proceeding ICONE15-10493, April 22–26, 2007

Dahlkild AA (2001) J Fluid Mech 428:249–272

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jomard, F., Feraud, J.P., Morandini, J. et al. Hydrogen filter press electrolyser modelled by coupling Fluent® and Flux Expert® codes. J Appl Electrochem 38, 297–308 (2008). https://doi.org/10.1007/s10800-007-9438-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10800-007-9438-6