Abstract

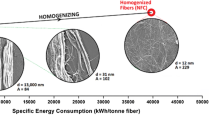

Microfibrillated celluloses (MFCs) with diameters predominantly in the range of 10–100 nm liberated from larger plant-based fibers have garnered much attention for the use in composites, coatings, and films due to large specific surface areas, renewability, and unique mechanical properties. Energy consumption during production is an important aspect in the determination of the “green” nature of these MFC-based materials. Bleached and unbleached hardwood pulp samples were processed by homogenization, microfluidization, and micro-grinding, to determine the effect of processing on microfibril and film properties, relative to energy consumption. Processing with these different methods affected the specific surface area of the MFCs, and the film characteristics such as opacity, roughness, density, water interaction properties, and tensile properties. Apparent film densities were approximately 900 kg/m3 for all samples and the specific surface area of the processed materials ranged from approximately 30 to 70 m2/g for bleached hardwood and 50 to 110 m2/g for unbleached hardwood. The microfluidizer resulted in films with higher tensile indices than both micro-grinding and homogenization (148 Nm/g vs. 105 Nm/g and 109 Nm/g, respectively for unbleached hardwood). Microfluidization and micro-grinding resulted in films with higher toughness values than homogenization and required less energy to obtain these properties, offering promise for producing MFC materials with lower energy input. It was also determined that a refining pretreatment required for microfluidization or homogenization can be reduced or eliminated when producing MFCs with the micro-grinder. A summary of the fiber and mechanical energy costs for different fibers and processing conditions with economic potential is presented.

Similar content being viewed by others

References

Abe K, Iwamoto S, Yano H (2007) Obtaining cellulose nanofibers with a uniform width of 15 nm from wood. Biomacromolecules 8(10):3276–3278

Andresen M, Stenius P (2007) Water-in-oil emulsions stabilized by hydrophobized microfibrillated cellulose. J Dispers Sci Technol 28:837–844

Andresen M, Johansson L, Tanem B, Stenius P (2006) Properties and characterization of hydrophobized microfibrillated cellulose. Cellulose 13:665–677

Chakraborty A, Sain M, Kortschot M (2005) Cellulose microfibrils: a novel method of preparation using high shear refining and cryocrushing. Holzforschung 59:102–107

Chinga-Carrasco G, Syverud K (2010) Computer-assisted quantification of the multi-scale structure of films made from nanofibrillated cellulose. J Nanopart Res 12:841–851

Clean Air Council (2006) Waste reduction & recycling: waste facts and figures. http://www.cleanair.org/Waste/wasteFacts.html. Accessed 18 July 2010

Erkisen O, Syverud K, Gregersen O (2008) The use of microfibrillated cellulose produced from kraft pulp as strength enhancer in TMP paper. Nordic Pulp Pap Res J 23(3):299–304

Goodrich J, Winter W (2007) a-Chitin nanocrystals prepared from shrimp shells and their specific surface area measurement. Biomacromolecules 8(1):252–257

Grande JA (2007) Biopolymers strive to meet price/performance challenge. Plast Tech. Available at http://www.thefreelibrary.com/Biopolymers+strive+to+meet+price%2fperformance+challenge.-a0161075965

Henriksson M, Henriksson G, Berglund L, Lindstrom T (2007) An environmentally friendly method for enzyme-assisted preparation of microfibrillated cellulose (MFC) nanofibers. Eur Polym J 43:3434–3441

Henriksson M, Berglund L, Isaksson P, Lindstrom T, Nishino N (2008) Cellulose nanopaper structures of high toughness. Biomacromolecules 9(6):1579–1585

Herrick F, Casebier R, Hamilton J, Sandberg K (1983) Microfibrillated cellulose: morphology and accessibility. J Appl Polym Sci Appl Polym Symp 37:797–813

Iwamoto S, Nakagaito AN, Yano H, Nogi M (2005) Optically transparent composites reinforced with plant fiber-based nanofibers. Appl Phys A Mat Sci Process 81:1109–1112

Janardhnan S, Sain M (2006) Isolation of cellulose microfibrils—an enzymatic approach. Bioresources 1(2):176–188

Kuehn B (2008) Plastic risks. J Am Med Assoc 299(20):2379

Lindstrom T, Ankerfors M, Henriksson G (2007) Method for the manufacturing of microfibrillated cellulose. International Patent WO 2007/091942 A1

Microfluidics Corporation (2010) Microfluidics. http://www.microfluidicscorp.com/. Accessed 18 July 2010

Montanari S, Roumani M, Huex L, Vignon MR (2005) Topochemistry of carboxylated cellulose nanocrystals resulting from TEMPO-mediated oxidation. Macromolecules 38:1665–1671

Nakagaito AN, Yano H (2004) The effect of morphological changes from pulp fiber towards nano-scale fibrillated cellulose on the mechanical properties of high-strength plant fiber based composites. Appl Phys A Mat Sci Process 78:547–552

Nakagaito AN, Yano H (2005) Novel high-strength biocomposites based on microfibrillated cellulose having nano-order-unit web-like network structure. Appl Phys A Mat Sci Process 80:155–159

Ougiya H, Hioki N, Watanabe K, Morinaga Y, Yoshinaga F, Samejima M (1998) Relationship between the physical properties and surface area of cellulose derived from adsorbates of various molecular sizes. Biosci Biotechnol Biochem 62(10):1880–1884

Plastics Technology (n.d.) Resin pricing. Available at http://www.ptonline.com/articles/prices-trending-upward-for-commodity-engineering-resins. Accessed March 2010

Saito T, Kimura S, Nishiyama Y, Isogai A (2007) Cellulose nanofibers prepared by TEMPO-mediated oxidation of native cellulose. Biomacromolecules 8:2485–2491

Siro I, Plackett D (2010) Microfibrillated cellulose and new nanocomposite materials: a review. Cellulose 17:459–494

Spence K, Venditti R, Habibi Y, Rojas O, Pawlak J (2010a) The effect of chemical composition on microfibrillar cellulose films from wood pulps: mechanical processing and physical properties. Bioresour Technol 101:5961–5968

Spence K, Venditti R, Rojas O, Habibi Y, Pawlak J (2010b) The effect of chemical composition on microfibrillar cellulose films from wood pulps: water interactions and physical properties for packaging applications. Cellulose 117:835–848

Stenstad P, Andresen M, Tanem B, Stenius P (2008) Chemical surface modifications of microfibrillated cellulose. Cellulose 15(1):35–45

Syverud K, Stenius P (2009) Strength and barrier properties of MFC films. Cellulose 16:75–85

T404 (1992) Tensile breaking strength and elongation of paper and paperboard (using pendulum-type tester). 2000–2001 TAPPI Test Methods. TAPPI

T410 (1998) Grammage of paper and paperboard (weight per unit area). 2000–2001 TAPPI Test Methods. TAPPI

T411 (1997) Thickness (caliper) of paper, paperboard, and combined board. 2000–2001 TAPPI Test Methods. TAPPI

T452 (1998) Brightness of pulp, paper, and paperboard (directional reflectance at 457 nm). 2000–2001 TAPPI Test Methods. TAPPI

T519 (1996) Difuse opacity of paper (d/0o paper backing). 2000–2001 TAPPI Test Methods. TAPPI

T527 (1994) Color of paper and paperboard (d/0o geometery). 2000–2001 TAPPI Test Methods. TAPPI

T555 (1999) Roughness of paper and paperboard (print-surf method). 2000–2001 TAPPI Test Methods. TAPPI

Taniguchi T, Okamura K (1998) New films produced from microfibrillated natrual fibres. Polym Int 47:291–294

Turbak A, Snyder F, Sandberg K (1983) Microfibrillated cellulose: a new cellulose product: properties, uses, and commercial potential. J Appl Polym Sci Appl Polym Symp 37:815–827

Acknowledgments

Support for this student training project is provided by USDA National Needs Graduate Fellowship Competitive Grant No. 2007-38420-17772 from the National Institute of Food and Agriculture. We would like to acknowledge Kevin Daniel for assistance in film testing and Linda McMurray, Ricardo Santos, and Ewellyn Capanema for assistance in pulp chemical composition analysis. The assistance of Dr. Jung Myoung Lee, Rachel Ernest, and Andy Cibils in the development of the film forming and pretreatment technique is appreciated. The cooperation of Microfluidics, Inc to complete this project was also greatly appreciated.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Spence, K.L., Venditti, R.A., Rojas, O.J. et al. A comparative study of energy consumption and physical properties of microfibrillated cellulose produced by different processing methods. Cellulose 18, 1097–1111 (2011). https://doi.org/10.1007/s10570-011-9533-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-011-9533-z