Abstract

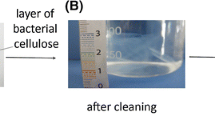

Bacterial cellulose (BC) films with different porosities have been developed in order to obtain improved mechanical properties. After 13 days of incubation of Gluconobacter xylinum bacteria in static culture, BC pellicles have been set. BC films have been compression molded after water dispersion of BC pellicles and filtration by applying different pressures (10, 50, and 100 MPa) to obtain films with different porosities. Tensile behavior has been analyzed in order to discuss the microstructure–property relationships. Compression pressure has been found as an important parameter to control the final mechanical properties of BC films where slightly enhanced tensile strength and deformation at break are obtained increasing mold compression pressure, while modulus also increases following a nearly linear dependence upon film porosity. This behavior is related to the higher densification by increasing mold compression pressure that reduces the interfibrillar space, thus increasing the possibility of interfibrillar bonding zones. Network theories have been applied to relate film elastic properties with individual nanofiber properties.

Similar content being viewed by others

References

Alemdar A, Sain M (2008) Biocomposites from wheat straw nanofibres: morphology, thermal and mechanical properties. Comp Sci Technol 68:557–565

Borosysiak S, Garbarczyk J (2003) Applying the WAXS method to estimate the supermolecular structure of cellulose fibres after mercerisation. Fibres & Text 11:104–106

Cox HL (1952) The elasticity and strength of paper and other fibrous materials. Brit J Appl Phys 3:72–79

Eichhorn SJ, Young RJ (2001) The Young’s modulus of a microcrystalline cellulose. Cellulose 8:197–207

Eichhorn SJ, Sirichaisit J, Young RJ (2001) Deformation mechanisms in cellulose fibres, paper and wood. J Mater Sci 36:3129–3135

Ganster J, Fink H-P, Fraatz J, Nywlt M (1994) Relation between structure and elastic constants of man-made cellulosic fibres: I. A two phase anisotropioc model with contiguity parameter. Acta Polymer 45:312–318

Gindl W, Keckes J (2004) Tensile properties of cellulose acetate butyrate composites reinforced with bacterial cellulose. Comp Sci Technol 64:2407–2413

Gushados G, Wan W, Hutter JL (2005) Measurement of the elastic modulus of single bacterial cellulose fibers using atomic force microscopy. Langmuir 21:6642–6646

Henriksson M, Berglund LA, Isaksson P, Lindström T, Nishino T (2008) Cellulose nanopaper structures of high toughness. Biomacromolecules 9:1579–1585

Hsieh YC, Yano H, Nogi M, Eichhorn S (2008) An estimation of the Young’s modulus of bacterial cellulose filaments. Cellulose 15:507–513

Iwamoto, Nakagaito AN, Yano H (2007) Nano-fibrillation of pulp fibers for the processing of transparent nanocomposites. Appli Phys A 89:461–466

Jin H, Zha C, Gu L (2007) Direct dissolution of cellulose in NaOH/thiourea/urea aqueous solution. Carbohydr Res 342:851–858

Johansson B, Alderborn G (2001) The effect of shape and porosity on the compression behaviour and tablet forming ability of granular materials formed from microcrystalline cellulose. Eur J Pharm Biopharm 52:347–357

Johansson B, Nicklasson F, Alderborn G (1998) Effect of pellet size on degree of deformation and densification during compresion and on compatibility of microcrystalline cellulose pellets. Int J Pharm 52:347–357

Klemm D, Heublein B, Fink HP, Bohn A (2005) Cellulose: fascinating biopolymer and sustainable raw material. Angew Chem Int Ed 44:3358–3393

Krenchel H (1964) Fibre reinforcement. Akademisk Forlag, Copenhagen

Kumar V, Kothari SH (1999) Effect of compressional force on the crystallinity of directly compressible cellulose excipients. Int J Pharm 177:173–182

Marx-Figini M (1987) Evaluation of the accessibility of celluloses by intrinsic viscosity ratio. Polym Bull 17:225–229

McCullough RL, Wu CT, Seferis JC, Lindenmeyer PH (1976) Predictions of limiting mechanical performance for anisotropic crystalline polymers. Polym Eng Sci 16:371–387

Mwaikambo LY, Ansell MP (2001) The determination of porosity and cellulose content of plant fibres by density method. J Mater Sci Lett 20:2095–2096

Nakagaito AN, Yano H (2004) The effect of morphological changes from pulp fiber towards nano-scale fibrillated cellulose on the mechanical properties of high-strength plant fiber based composites. Appl Phys A: Mater Sci Process 78:547–552

Nakagaito AN, Iwamoto S, Yano H (2005) Bacterial cellulose: the ultimate nano-scalar cellulose morphology for the production of high-strength composites. Appl Phys A: Mater Sci Process 80:93–97

Nishi Y, Uryu M, Yamanaka S, Watanabe K, Kitamura N, Iguchi M, Mitsuhashi S (1990) The structure and mechanical properties of sheets prepared from bacterial cellulose. J Mater Sci 25:2997–3001

Putra A, Kakugo A, Furukawa H, Gong JP, Osada Y (2008) Tubular bacterial cellulose gel with oriented fibrils on the curved surface. Polymer 49:1885–1891

Segal L, Creely J, Martin A, Conrad C (1959) An empirical method for estimating the degree of crystallinity of native cellulose using the X-ray diffractometer. Text Res J 29:786–794

Watanabe K, Tabuchi M, Morinaga Y, Yoshinaga F (1998) Structural features and properties of bacterial cellulose produced in agitated culture. Cellulose 5:187–200

Yamanaka S, Ishihara M, Sugiyama J (2000) Structural modification of bacterial cellulose. Cellulose 7:213–225

Yan Z, Chen S, Wang H, Wang B, Wang C, Jiang J (2008) Cellulose synthesized by Acetobacter xylinum in the presence of multi-walled carbon nanotubes. Carbohydr Res 343:73–80

Zuluaga R, Putaux JL, Cruz J, Vélez J, Mondragon I, Gañan P (2009) Cellulose microfibrils from banana rachis: effect of alkaline treatments on structural and morphological features. Carbohydr Polym 76:51–59

Acknowledgments

The authors gratefully acknowledge Eusko Jaurlaritza, Grupo Consolidado IT-365-07 and ETORTEK-inanoGUNE for financial assistance to carry out this investigation.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Retegi, A., Gabilondo, N., Peña, C. et al. Bacterial cellulose films with controlled microstructure–mechanical property relationships. Cellulose 17, 661–669 (2010). https://doi.org/10.1007/s10570-009-9389-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-009-9389-7