Abstract

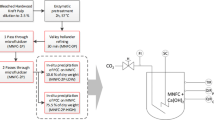

A new concept for both furnish composition and z-directional furnish arrangement involving the interaction between specific thermo-mechanical pulp fractions (TMP), nanofibrillated cellulose (NFC) and clay in oriented layered laboratory sheets is presented. Used separately, NFC improves the strength properties of paper while fillers enhance the optical properties. Synergy effects of clay–NFC interactions are assessed. The study comprises a structural assessment, including laser profilometry, scanning electron microscopy (SEM) and field-emission (FE)-SEM analyses. In addition, optical and strength properties are assessed. It is demonstrated that a potential reduction of strength properties caused by filler addition may be counteracted by appropriate NFC addition to specific layers in the z-direction. Based on an estimation of an overall quality index considering five variables, it is concluded that the best sheet construction is obtained when placing the fillers in surface layers with the TMP accept fraction and the NFC in the centre of the sheets together with the refined TMP reject fraction.

Similar content being viewed by others

References

Abe K, Iwamoto S, Yano H (2007) Obtaining cellulose nanofibers with a uniform width of 15 nm from wood. Biomacromolecules 8(10):3276–3278. doi:10.1021/bm700624p

Abramoff MD, Magelhaes PJ, Ram SJ (2004) Image processing with ImageJ. Biophotonics int 11(7):36–42

Ahola S, Österberg M, Laine J (2008) Cellulose nanofibrils—adsorption with poly(amideamine) epichlorohydrin studied by QCM-D and application as a paper strength additive. Cellulose 15(2):303–314. doi:10.1007/s10570-007-9167-3

Andresen M, Johansson L-S, Tanem BS, Stenius P (2006) Properties and characterization of hydrophobized microfibrilated cellulose. Cellulose 13:665–677. doi:10.1007/s10570-006-9072-1

Bristow JA, Pauler N (1983) Multilayer structures in printing papers. Sven Papperstidn 86(15):R164–R172

Brown RM, Montezinos D (1976) Cellulose microfibrils: visualization of biosynthetic and orienting complexes in association with the plasma membrance. Proc Natl Acad Sci USA 73:143–147. doi:10.1073/pnas.73.1.143

Chinga G, Diserud O, Lunden-Berli E (2007a) On surface details affecting the quality of commercial SC papers for gravure printing. Nordic Pulp Pap Res J 22(3):331–335. doi:10.3183/NPPRJ-2007-22-03-p331-335

Chinga G, Solheim O, Mörseburg K (2007b) Cross-sectional dimensions of fiber and pore networks based on Euclidean distance maps. Nordic Pulp Pap Res J 22(4):500–507. doi:10.3183/NPPRJ-2007-22-04-p500-507

Chinga G, Johnsen PO, Dougherty R, Lunden-Berli E, Walter J (2007c) Quantification of the 3D microstructure of SC surfaces. J Microscopy-Oxford 227(3):254–265. doi:10.1111/j.1365-2818.2007.01809.x

Chinga-Carrasco G (2009) Exploring the multiscale structure of printing paper—a review of modern technology. J Microscopy-Oxford (in press)

Eriksen Ø, Syverud K, Gregersen Ø (2008) The use of microfibrillated cellulose produced from kraft pulp as a strength enhancer in TMP paper. Nordic Pulp Pap Res J 23(3):299–304. doi:10.3183/NPPRJ-2008-23-03-p299-304

Fernandez EO, Young RA (1994) An explanation for the deviation from linearity in properties of blends of mechanical and chemical pulps. Tappi J 77(3):221–224

Frey-Wyssling A, Mühlethaler K (1963) Die elementarfibrillen der cellulose. Makromol Chem 62:25–31. doi:10.1002/macp.1963.020620103

Gardner DJ, Oporto GS, Mills R, Samir MASA (2008) Adhesion and surface issues in cellulose and nanocellulose. J Adhes Sci Technol 22:545–567. doi:10.1163/156856108X295509

Häggblom-Aghner U (1998) Layering of office paper. Pap Puu 80(7):508–513

He J, Batchelor WJ, Johnston RE (2007) An analytical model for number of fibre-fibre contacts in paper and expressions for relative bonded area (RBA). J Mater Sci 42(2):522–528. doi:10.1007/s10853-006-1146-9

Herrick FW, Casebier RL, Hamilton JK, Sandberg KR (1983) Microfibrillated Cellulose: morphology and accessibility. J Appl Polym Sci Appl Polym Symp 37:797–813

Holmstad R, Kure KA, Chinga G, Gregersen Ø (2004) Effect of temperature gradient multi-nip calendering on the structure of SC paper. Nordic Pulp Pap Res J 19(4):489–494. doi:10.3183/NPPRJ-2004-19-04-p489-494

Ingmanson WL, Thode EF (1959) Factors contributing to the strength of a sheet of paper. Tappi 42(1):83–93

Ioelovich M (2008) Nanostructured cellulose. BioResources 3(4):1403–1418 Review

Iwamoto S, Abe K, Yano H (2008) The effect of hemicelluloses on wood pulp nanofribrillation and nanofiber network characteristics. Biomacromolecules 9:1022–1026. doi:10.1021/bm701157n

Jähne B (1993) Filterdesign. In: Digitale Bildbearbeitung. Springer, Berlin, pp 112–118

Kinnunen JS, Lloyd MD, Nygren-Konttinen A (1998) A new world of papermaking—the layered SC-paper. Pap Puu 80(3):167–171

Mohlin UB, Ölander K (1986) The influence of mechanical pulp quality on the properties of filler containing papers. Nordic Pulp Pap Res J 1(4):44–51. doi:10.3183/NPPRJ-1986-01-04-p044-051

Mohlin UB, Wennberg K (1984) Some aspects of the interaction between mechanical and chemical pulps. Tappi J 67(1):90–93

Moor H (1959) Platin-Kohle-Abdruck-Technik angewandt auf den Feinbau der Milcröhren. J Ultrastruct Res 2:393–422. doi:10.1016/S0022-5320(59)90003-6

Ohad I, Danon D (1964) On the dimensions of cellulose microfibrils. J Cell Biol 22(1):302–305. doi:10.1083/jcb.22.1.302

Pääkkö M, Ankefors M, Kosonen H, Nykänen A, Ahola S, Österberg M, Ruokolainen J, Laine J, Larsson PT, Ikkala O, Lindström T (2007) Enzymatic hydrolysis combined with mechanical shearing and high-pressure homogenization for nanoscale cellulose fibrils and strong gels. Biomacromolecules 8:1934–1941. doi:10.1021/bm061215p

Page DH (1969) A theory for the tensile strength of paper. Tappi 52(4):674–681

Puurtinen A (2004) Controlling filler distribution for improved fine paper properties. Appita J 57(3):204–209

Retulainen E (1991) Properties of mechanical and chemical pulp blends. Int Pap Phys Conf 1991(2):449–462

Retulainen E, Moss P, Nieminen K (1993) Effect of fines on the properties of fibre networks. In: 10th Fundamental Research Symposium Oxford, vol 2, pp 727–769

Svagan AJ, Azizi Samir MAS, Berglund LA (2008) Biomimetic foams of high mechanical performance based on nanostructured cell walls reinforced by native cellulose nanofibrils. Avd Mater 20:1263–1269. doi:10.1002/adma.200701215

Syverud K, Stenius P (2009) Strength and barrier properties of MFC films. Cellulose 16(1):75–85. doi:10.1007/s10570-008-9244-2

Taniguchi T, Okamura K (1998) New films produced from microfibrillated natural fibres. Polym Int 47(3):291–294. doi:10.1002/(SICI)1097-0126(199811)47:3<291::AID-PI11>3.0.CO;2-1

Turbak AF, Snyder FW, Sandberg KR (1983) Microfibrillated cellulose, a new cellulose product: properties, uses, and commercial potential. J Appl Polym Sci Appl Polym Symp 37:815–827

Wågberg L, Decher G, Norgren M, Lindström T, Ankefors M, Axnäs K (2008) The build-up of polyelectrolyte multilayers of microfibrillated cellulose and cationic polyelectrolytes. Langmuir 24:784–795. doi:10.1021/la702481v

Acknowledgments

The authors thank Norske Skog Industrier ASA for financial and technical support, cooperation and permission to publish this work. Kristin Syverud and Øyvind Eriksen (PFI) are acknowledged for providing the nanofibrillated cellulose sample and product information. Ida Christiansen, Berit Leinsvang, Oksana Kalouzskaya, Merete Wiig, Kenneth Aasarød and Trond Karlsen (PFI) are acknowledged for their dedicated work at the laboratories. Kristin Syverud (PFI), Øyvind Gregersen (NTNU), Jan Hill (Norske Skog ASA) and Lars Johansson (PFI) are thanked for commenting the manuscript.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mörseburg, K., Chinga-Carrasco, G. Assessing the combined benefits of clay and nanofibrillated cellulose in layered TMP-based sheets. Cellulose 16, 795–806 (2009). https://doi.org/10.1007/s10570-009-9290-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-009-9290-4