Abstract

The aim of this study was to investigate convenient spectroscopic evaluation method of Para rubber quality. Ultra violet–near infrared (UV–NIR 370–1085 nm) spectra of latex were measured in transmittance mode. Calibrations for total solid content (TSC) and dry rubber content (DRC) were developed using spectral data set with aid of partial least square regression analysis using 57 samples. UV–NIR spectra of latex provided good regression models between measured and predicted values of TSC and DRC with determination coefficient for cross-validation of 0.96 and 0.97, respectively. The ranks were 2 and 1, respectively. This study suggests high accuracy in-line quality control of latex using UV–NIR spectroscopy. The long wavelength NIR spectra of bark were scanned to check the feasibility of on-site evaluation of latex quality by measuring the NIR spectra of standing tree. From the observation of near infrared spectra, it was shown that there was more latex signal in outer part of wood bark than in inner part of wood bark. This result suggests that the focal point should be on the outer part of bark to get the signal of latex when we measure the spectra of standing tree.

Similar content being viewed by others

Introduction

Para rubber tree (Hevea brasiliensis) is a major economically important bio-resource because its sap-like extract (known as latex) can be collected and is the primary source of natural rubber. The white or yellow latex occurs in latex vessels in the bark, mostly outside the phloem. According to world food and agriculture organization (FAO) statistics, in 2010, Thailand produced the highest quantity (3,051,780 metric tons) of natural rubber in the world followed by Indonesia (2,788,300 metric tons) and Malaysia (858,900 metric tons) [1]. International Rubber Study Group (IRSG) estimated the production of Para rubber of the world in 2011 to be 10.7 million tons which is more than that of the year 2010 (10.2 million tons) [2]. Main Para rubber products include field latex, concentrated latex, rubber sheet, crepe, and block rubber. Incisions are made orthogonally to the latex vessels, just deep enough to tap the vessels without harming the tree’s growth, and the sap is collected in small buckets. It is known that harvesting can be started once the trees are 5–6 years old. The field latex is the primary raw material for other processes. Total solid content (TSC) and dry rubber content (DRC) of field latex are the most important parameters in trading. However, the conventional wet-lab measurement procedures in terms of these parameters are time consuming and require technical experts. Therefore, it is preferable to introduce convenient evaluation technique at in-line process for rubber products or on-site work of Para rubber tree plantation.

NIR spectroscopy, which is rapid, inexpensive, non-destructive and precise technology, is one of the best methods for the prediction of TSC and DRC. NIR spectroscopy has been investigated in evaluation of wood properties such as chemical components, anatomical or pulping traits and mechanical properties [3–8]. Furthermore, Rittiron et al. [9] recently reported that a handheld NIR spectrometer could be useful as an evaluation of moisture content of rubber sheet. Marinho and Monteiro [10] reported the determination of cis- and trans-polyisoprene, which are main chemical components of rubber, using NIR spectroscopy. Sirisomboon et al. [11] reported the accurate prediction of apparent viscosity of Para rubber field latex and concentrated latex over the range of 1000–2500 nm. The reports strongly suggest that NIR technique is applicable for nondestructive measurement of Para rubber. Actually, other electromagnetic wave region (i.e., UV and visible light region where there is the absorption due to electron transition, and THz region where there is the absorption due to molecules rotation transition) might be also useful to evaluate rubber quality. As time-effective and cost-effective evaluation tool is required in latex processing factory, we investigated the application of ultra violet–near infrared (UV–NIR) spectra of latex collected for the quality control of latex. The UV–NIR spectrophotometer is cheaper and smaller than NIR spectrometer. Furthermore, we measured NIR spectra of bark cut from the standing trees to check the feasibility of NIR spectroscopy for on-site evaluation at rubber tree plantation.

Materials and methods

Samples and spectral measurement

Harvested latex was measured using UV–NIR (370–1085 nm) spectrophotometer in transmittance mode (Type A: AvaSpec-2048-USB2-VA-50, Avantes, the Netherlands). DRC and TSC were predicted using each spectrum with aid of partial least square regression (PLS-R) analysis.

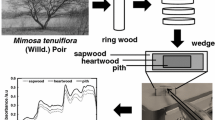

57 latex samples and 21 bark samples were taken from 13-, 19-, and 20-year old Para rubber trees for the experiment. Trees of each age were randomly selected from the commercial Para rubber orchards of NY rubber company in Nongyai district, Chonburi province, Thailand. In the rubber plantation, incisions are made orthogonally to the latex vessels, just deep enough to tap the vessels to take latex. The latex flowed down along the cut line into a bowl overnight and it stopped flowing in the morning. The latex of each tree was collected and the yield measured by weighing. Then latex samples were immediately brought to the factory. UV–NIR spectra of latex were measured in transmittance mode using 10 × 5 mm quartz cell (optical path length 5 mm, wavelength range 370–1085 nm, wavelength interval 0.6 nm, wavelength resolution 2.4 nm). As shown in Fig. 1, bark consists of some cells. Periderm is the outmost layer which consisted of non-living cells. Cortex is developed from ground meristem and consisted mostly of parenchyma cells. There are also sclereid cells or stone cells and latex vessel called laticifer. Hard bark exists between cortex and inner bark. There is high density of stone cell which make the latex vessel incomplete and hard texture of bark. Soft bark exists between hard bark and cambium. In this study, we also took bark samples back to laboratory to measure the NIR spectra. Bark samples were divided into outer part including periderm, cortex and hard bark and inner part including soft bark. Divided bark samples were milled for 30 s by crusher (LR-04, Sansho industry), after the drying for 8 h in 105 °C condition. NIR spectra of inner and outer part of bark were measured in reflectance mode using FT-NIR spectrometer [Matrix-F, Bruker optics, wavenumber (wavelength) range: 10000–4000 cm−1 (1000–2500 nm), wavenumber interval: 4 cm−1, wavenumber resolution: 8 cm−1].

DRC and TSC of latex were measured following the standard method of Rubber Research Institute in Thailand [12] which referred to ISO 126: 1995 and ISO 124: 1997, respectively.

For DRC, the samples of 5 ± 0.5 g of rubber content without bubbles were weighed in stainless steel dishes, with 0.0001 g resolution, using an electronic balance (A200S, Sartorius, Germany). Distilled water (5 ml) was then mixed into the sample and the dish was rotated by hand. Then, 20 ml of 2 % acetic acid was added slowly and the latex coagulated. The dish containing the sample was then placed on a steam bath (WE760, Memmert, USA) for approximately 10–20 min to complete coagulation, and the clear serum was separated from the latex clumps. Then the clumps of latex were washed by water and pressed by rollers to obtain a thin sheet sample approximately 2 mm thick, which was placed into a hot-air oven (UL600, Memmert, USA) at 70 °C for 12–14 h to cure. The rubber sheet samples were cooled in a dessicator for 30 min and reweighed, and the % DRC was calculated by the formula

where M0 = Weight of latex sample (g), M1 = Weight of dried rubber sheet (g).

For TSC, the 1 ± 0.5 g rubber latex without bubble sample was weighed in 80-cm-diameter Petri dish with 0.0001 g resolution electric balance (Adventurer AR2140, OHAUS, USA). The latex was spread out on the dish by tilting the dish and rotate it at the same time, and the sample was kept in hot-air oven (UL600, Memmert, USA) at 70 °C for 12–14 h. Then the samples were cooled in a desiccator for 30 min, and weighed with the same balance and then the %TSC was calculated by the formula

where M0 = Weight of wet sample (g), M1 = Weight of dried sample (g).

PLS-R

DRC and TSC were predicted by PLS-R analysis using UV–NIR spectra. OPUS Quant 2 software (Bruker optics) was used for data pre-processing and for the calculation and validation of the PLS-R models. Optimum spectral pre-treatment which gives lowest root mean square error of cross-validation (RMSECV) was used for the calculation of the PLS-R models with OPUS software. For calibration/cross-validation, the spectral data sets were regressed against the property of interest. The optimum number of PLS components (Rank) was determined by full inner cross-validation method (leave one out). Calibration, cross-validation and test set validation performance were evaluated by the coefficient of determination (R 2 for calibration and r 2 for cross-validation) between predicted and measured values, and RMSECV. Total of 57 latex samples were available for the NIR spectral measurement. Furthermore, a total number of 57 latex samples were divided into 2 independent sample sets, i.e., a calibration set and a prediction set to omit the over-fitting result that is more realizable for future application. 30 % of samples (17 samples) were randomly selected as prediction set. A large number of different spectral pre-treatments were applied and were tested in combination over several wavenumber ranges to find the best regression result.

Result and discussion

Variation of TSC, DRC and yield as a function of tree age

Figure 2 shows the variation of TSC, DRC and yield as a function of tree age. White filled circles indicate the average value. The correlation coefficient value between TSC, DRC, tree age and latex yield was shown in Table 1. TSC and DRC have strong relation. TSC and DRC values do not have any strong relation with tree age.

Prediction of rubber quality

DRC and TSC were predicted by PLS-R analysis using UV-NIR spectra. Statistical value of conventionally measured TSC and DRC are shown in Table 2. Cross-validation results of PLS-R analysis are shown in Table 3. Figure 3 shows relation between measured and predicted value from spectra. Predicted TSC and DRC values from UV–NIR spectra of latex were well corresponded to conventionally measured value. The coefficients for determination of cross-validation of TSC and DRC were 0.96 and 0.97, respectively. RMSECV for each PLS-R model was adequately small. The optimum number of PLS components are 2 and 1 for TSC and DRC, respectively. The coefficients for determination of test set validation of TSC and DRC were 0.95 and 0.97, respectively. Determination coefficients of test set validation are smaller compared to that of cross-validation. However, they are still sufficiently accurate. Although Sirisomboon et al. [11] reported the accurate prediction of apparent viscosity of Para rubber field latex and concentrated latex over the range of 1000–2500 nm, this study demonstrated the ability of UV–NIR region (i.e., 370–1085 nm) as in-line prediction of Para rubber quality. UV–NIR spectrophotometer employed in this study was smaller and cheaper than the conventional NIR spectrophotometer. As time-effective and cost-effective evaluation tool is required, such device will be promoted in latex factory.

Relation between measured and predicted value of a DRC, cross-validation, b TSC, cross-validation, c DRC, test set validation and d TSC, test set validation. r 2 coefficient of determination for cross-validation, RMSECV root mean square error of cross-validation, RPD ratios of performance to deviation. Solid line shows the regression line constructed by PLS regression analysis and dashed line shows target line

Variation in UV–NIR spectra

Figure 4 shows the (a) UV–NIR transmittance spectra (380–1080 nm), (b) their first derivative spectra and (c) correlation coefficient vector between derivative spectra of latex and TSC values. Figure 5 also shows the (a) NIR spectra of latex measured in reflectance mode and (b) correlation coefficient vector between reflectance spectra of latex and TSC values (1500–2500 nm). The experimental arrangement has been described in detail elsewhere [11]. Well-resolved bands of natural rubber are seen at 1700–1780 and 2300–2500 nm in the NIR spectral region (see. Fig. 5a). The CH first overtone gives a number of bands from 1715 to 1780 nm, especially strong absorbance features at 1716 nm consistent with chemical features associated with the CH=CH, CH2 or CH3 vibrations [13]. It was shown that the most evident differences between the spectra of cis-1, 4 and trans-1, 4 polyisoprenes are in the intensities of the absorption at 2466 nm assigned as combination of C–H absorption mode [10]. Specifically, the major peaks centered around 2310 nm can be assigned to different methyl or methylene combination or overtone vibrations [14–15]. Intense water band is apparent at around 1950 nm. It is clear that the higher TSC latex contained less water. Absorption intensity at 1715–1780 nm and 2300–2500 nm increased as a function of TSC value. The correlation coefficient value between spectra and TSC value at water absorption peak is almost −1, while that at 1715–1780 and 2300–2500 nm is almost 1, because TSC means the relative amount of total solid content in latex which consists of water and total solid constituents. In spite of continuing studies on the assignment of isoprene, which is the major component of latex, in ultraviolet (UV), NIR and mid-infrared (MIR) region [14–18], there has been little research due to UV–NIR spectra of latex. Rittiron [9] reported that the absorption peak around 900 nm is due to CH3 and CH2 third overtone of isoprene. In this study, absorption peak around 900 nm increased as a function of TSC value (Fig. 4a, b). Intense water band at 980 nm decreased with TSC values. The tendency of water absorption bands and latex itself with TSC value are quite similar between NIR region and UV–NIR region.

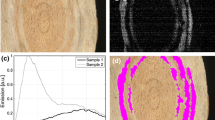

NIR spectra of rubber tree bark

We also measured long wavelength NIR spectra of bark to check the feasibility of on-site evaluation of latex quality by measuring the NIR spectra of standing tree. There have been little achievements of evaluation of latex quality due to NIR spectra of standing wood because depth of penetration of NIR radiation is enough to reach sap wood. However, as the purpose of this research is to detect the latex information mainly included in that of bark, it might be possible to evaluate the latex quality from standing tree. In order to make good calibration curve for latex from NIR spectra of para rubber tree, the absorption intensity of latex must be relatively high value compared to other absorption intensity of woody cell (cellulose, hemicelluloses, lignin and extractives) and water. Figure 6 shows (a) NIR reflectance spectra of latex, oven-dried bark inner part, oven-dried bark outer part and oven-dried xylem, and (b, c) second derivative spectra. These spectra are the average of 20 bark samples. The NIR spectra of the latex sample were similar to that of isoprene reported by some researchers. Absorption bands due to latex (1700, 1716, 1780, 2310 and 2446 nm) are also observed in NIR spectra of outer part of bark, although same bands cannot be observed in the spectra of inner part of bark and xylem. Absorption bands around 1900 and 2400 nm are due to water. It is confirmed by spectroscopic method that latex are more abundant in outer part of bark than inner part. This result suggests that the strict adjustment of optical focal point to acquire good spectra of outer part of bark is required to get the spectral signal of latex.

Conclusions

This study demonstrated the applicability of two kinds of spectroscopy for the evaluation of latex quality at in-line or on-site condition. UV–NIR (370–1085 nm) spectra of latex in transmittance mode were employed for the prediction of TSC and DRC values with aid of PLS-R. PLS-R analysis using UV–NIR spectra of latex provided good regression models between measured and predicted values for TSC and DRC. As UV–NIR spectrophotometer employed in this study was smaller and cheaper than the conventional NIR spectrophotometer, it will be promoted for the in-line measurement in latex factory. From the observation of near infrared spectra, it was shown that there was more latex signal in outer part of wood bark than in inner part of wood bark. This result suggests that the focal point should be on the outer part of bark to get the signal of latex when we measure the spectra of standing tree.

References

FAO (2012) FAOSTAT. (http://faostat.fao.org/site/339/default.aspx). Accessed 24 Sep 2012

Pipitkul P, Chomtoranin J (2010) Para rubber, October 2010 (in Thai). J Agric Econ 56:32–33

Schimleck LR, Hodge GR, Woodbridge W (2010) Toward global calibrations for estimating the wood properties of tropical, sub-tropical and temperate pine species. J Near Infrared Spectrosc 18:355–365

Inagaki T, Schwanninger M, Kato R, Kurata Y, Thanapase W, Puthson P, Tsuchikawa S (2012) Eucalyptus camaldulensis density and fiber length estimated by near-infrared spectroscopy. Wood Sci Technol 46:143–155

Terdwongworakul A, Punsuwan V, Thanapase W, Tsuchikawa S (2005) Rapid assessment of wood chemical properties and pulp yield of Eucalyptus camaldulensis in Thailand tree plantations by near infrared spectroscopy for improving wood selection for high quality pulp. J Wood Sci 51:167–171

Kelley SS, Rials TG, Snell R, Groom LH, Sluiter A (2004) Use of near infrared spectroscopy to measure the chemical and mechanical properties of solid wood. Wood Sci Technol 38:257–276

Schwanninger M, Rodrigues JC, Fackler K (2011) A review of band assignments in near infrared spectra of wood and wood components. J Near Infrared Spectrosc 19:287–308

Tsuchikawa S (2007) A review of recent near infrared research for wood and paper. Appl Spectrosc Rev 42:43–71

Rittiron R, Tiammueng C, Saehea J, Sabchuangchote S (2010) Moisture content analyzer for raw rubber sheet by handheld near infrared spectrometer. In: Saranwong S, Kasemsumran S, Thanapase W, Williams (eds) Near Infrared Spectroscopy: Proceedings of the 14th International Conference, IM Publications LLP, UK, pp 1079–1085

Marinho JRD, Monteiro EEC (2000) Analysis of natural cis- and trans-polyisoprene mixtures by near-infrared spectrophotometry. Polym Test 19:667–672

Sirisomboon P, Chowbankrang R, Williams P (2012) Evaluation of apparent viscosity of Para rubber latex by diffuse reflection near-infrared spectroscopy. Appl Spectrosc 66:595–599

Rubber Research Institute (2001) Testing methods for concentrated latex (in Thai), Department of Agriculture, Technical Paper No. 2/2544, 4th edition/2544: pp 13–19

Corish PJ (1959) Analysis of cis-1 and trans-1-4 contents of polyisoprenes by near infra-red spectroscopy. Spectrochim Acta 15:598–604

Black LT, Hamerstrand GE, Kwolek WF (1985) Analysis of rubber, resin, and moisture-content of guayule by near-infrared reflectance spectroscopy. Rubber Chem Technol 58:304–313

Guilment J, Bokobza L (2001) Determination of polybutadiene microstructures and styrene-butadiene copolymers composition by vibrational techniques combined with chemometric treatment. Vib Spectrosc 26:133–149

Traetteberg M, Paulen G, Cyvin SJ, Panchenko YN, Mochalov VI (1984) Structure and conformations of isoprene by vibrational spectroscopy and gas electron-diffraction. J Mol Struct 116:141–151

Vilmin F, Dussap C, Coste N (2006) Fast and robust method for the determination of microstructure and composition in butadiene, styrene-butadiene, and isoprene rubber by near-infrared spectroscopy. Appl Spectrosc 60:619–630

Quinebeche S, Navarro C, Gnanou Y, Fontanille M (2009) In situ mid-IR and UV-visible spectroscopies applied to the determination of kinetic parameters in the anionic copolymerization of styrene and isoprene. Polymer 50:1351–1357

Acknowledgments

The authors are grateful for the financial support of the research budget of King Mongkut’s Institute of Technology Ladkrabang (Fiscal year 2010). Also the authors are very thankful to Mr. Chanwit Khunnarong, the manager of NY Rubber company at Nong Yai, Cholburi, Thailand, for providing some instrument and place to conduct the experiment.

Author information

Authors and Affiliations

Corresponding author

Additional information

T. Inagaki equally contributed to this work.

About this article

Cite this article

Inagaki, T., Sirisomboon, P., Liu, C. et al. High accuracy rapid prediction and feasibility of on-site nondestructive estimation of Para rubber quality by spectroscopic methods. J Wood Sci 59, 119–126 (2013). https://doi.org/10.1007/s10086-012-1305-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10086-012-1305-3