Abstract

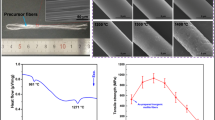

Nanostructured polycrystalline titania (TiO2) microfibers were produced by direct drawing from visco-elastic alkoxide precursors. The fiber crystallinity and grain size were shown to depend on post-treatment calcination temperature. Tensile tests with individual fibers showed strong sensitivity of the elastic modulus and the tensile strength to microstructural details of the fibers. The elastic modulus of as-fabricated fibers increased about 10 times after calcination at 700 ∘C, while the strain at failure remained almost the same at ∼1.4 %. The highest tensile strength of more than 800 MPa was exhibited by nanoscale grained fibers with a bimodal grain size distribution consisting of rutile grains embedded into an anatase matrix. This structure is believed to have reduced the critical defect size, and thus increased the tensile strength. The resultant fibers showed properties that were appropriate for reinforcement of different matrixes.

Similar content being viewed by others

References

S.J. Park, G.G. Chase, K.U. Jeong, H.Y. Kim, J. Sol-Gel Sci. Technol. 54, 188–194 (2010)

C. Kaya, F. Kaya, E.G. Butler, A.R. Boccaccini, K.K. Chawla, J. Eur. Ceram. Soc. 29, 1631–1639 (2009)

A. Demir, D.Z. Tatli, Composites, Part A, Appl. Sci. Manuf. 35, 1433–1440 (2004)

R. Pärna, U. Joost, E. Nõmmiste, T. Käämbre, A. Kikas, I. Kuusik, M. Hirsimäki, I. Kink, V. Kisand, Appl. Surf. Sci. 15, 6897–6907 (2011)

G. Kermouche, J.L. Loubet, J.M. Bergheau, Mech. Mater. 40, 271–283 (2008)

S.H. Lee, C. Tekmen, W.M. Sigmund, Mater. Sci. Eng. A, Struct. Mater.: Prop. Microstruct. Process. 398, 77–81 (2005)

D. Li, Y. Xia, Adv. Mater. 16, 1151–1170 (2004)

G. Larsen, R. Velarde-Ortiz, K. Minchow, A. Barrero, I.G. Loscertales, J. Am. Chem. Soc. 125, 1154–1155 (2003)

W.K. Son, D. Cho, W.H. Park, Nanotechnology 17, 439–443 (2006)

T. Tatte, M. Paalo, V. Kisand, V. Reedo, A. Kartushinsky, K. Saal, U. Mäeorg, A. Lõhmus, I. Kink, Nanotechnology 18, 125301 (2007)

L.A. Feigin, D.I. Svergun, Structure Analysis by Small-Angle X-ray and Neutron Scattering (Plenum Press, New York, 1987)

H. Mändar, J. Felsche, V. Mikli, T. Vajakas, J. Appl. Crystallogr. 32, 345–350 (1999)

K. Jonnalagadda, I. Chasiotis, S.Y.J. Lambros, R. Polcawich, J. Pulskamp, M. Dubey, Exp. Mech. 50(1), 25–35 (2010)

P.V. Konarev, M.V. Petoukhov, V.V. Volkov, D.I. Svergun, J. Appl. Crystallogr. 39, 277–286 (2006)

T. Tätte, M. Hussainov, J. Gurauskis, H. Mändar, G. Kelp, R. Rand, M. Paalo, K. Hanschmid, I. Hussainova, in Technical Proceedings of the 2010 NSTI Nanotechnology Conference & Expo—Nanotech 2010. Vol. 2: Nanotechnology 2010: Electronics, Devices, Fabrication, MEMS, Fluidics and Computational, Anaheim, CA, USA, 21–25 June 2010, pp. 245–248. ISBN 978-1-4398-3402-2

T. Tätte, M. Hussainov, M. Paalo, M. Part, R. Talviste, V. Kiisk, H. Mändar, K. Põhako, T. Pehk, K. Reivelt, M. Natali, J. Gurauskis, A. Lõhmus, U. Mäeorg, Sci. Technol. Adv. Mater. 12, 034412 (2011)

S. Sakka, K. Kamiya, Mater. Sci. Res. 17, 83–94 (1984)

J. Aarik, A. Aidla, H. Mändar, T. Uustare, M. Schuisky, A. Hårsta, J. Cryst. Growth 242, 189–198 (2002)

D.-L. Shieh, C.-H. Ho, J.-L. Lin, Microporous Mesoporous Mater. 109, 362–369 (2008)

J. Craido, C. Real, J. Chem. Soc. Faraday Trans. 79, 2765 (1983)

J.K. Park, J.P. Ahn, G. Kim, Met. Mater. Int. 5, 129–135 (1999)

D.A.H. Hanaor, C.C. Sorrell, J. Mater. Sci. 46, 855–874 (2011)

I.M. Low, F.K. Yam, W.K. Pang, Mater. Lett. 87, 150–152 (2012)

J. Zhang, M. Li, Z. Feng, J. Chen, C. Li, J. Phys. Chem. B 110, 327–337 (2006)

P.I. Gouma, M.J. Mills, J. Am. Ceram. Soc. 84, 619–622 (2001)

H. Wang, J.P. Lewis, J. Phys. Condens. Matter 18, 421–434 (2006)

Acknowledgements

This work was partially founded from European Social Fund’s program DoRa, supported by the European Union through the European Regional Development Fund (Centre of Excellence “Mesosystems: Theory and Applications,” TK114), by Estonian Science Foundation grants 7612, 8377, 9292, 7603, graduate school “Functional materials and processes” funded from the European Social Fund under project 1.2.0401.09-0079 in Estonia, ESF FANAS program NANOPARMA and Centre of Excellence TK117 “High-Technology Materials for Sustainable Development,” and Estonian Research Council grant IUT 2-24.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hanschmidt, K., Tätte, T., Hussainova, I. et al. Optimization of mechanical strength of titania fibers fabricated by direct drawing. Appl. Phys. A 113, 663–671 (2013). https://doi.org/10.1007/s00339-013-7601-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00339-013-7601-y