Summary

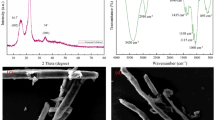

Carboxymethylcellulose (CMC, DSCM = 1) was partially hydrophobized in order to prepare polymeric surfactants by the transesterification reaction using the methyl ester of the fatty acid complex of rapeseed oil (MERO). The chemical modification was performed in different reaction media (i) DMF/TSA and (ii) H2O/DMF with and without K2CO3 as catalyst, at various reaction conditions and using microwave radiation with controlled power as heating source. The obtained MERO-hydrophobized CMC (MH-CMC) comprising mixed fatty acyl esters were characterized by FT-IR and NMR spectroscopic techniques, which indicated a very low degree of esterification (DS < 0.1). The derivatives showed, in spite of moderate surface tension-lowering effects, excellent emulsifying activity for ‘oil in water’ type emulsions as well as good performance properties including washing power and antiredeposition efficiency. The results suggested that surface-active MH-CMC derivatives can be prepared under microwave heating at reaction times in the range of several minutes, what is a great advantage in comparison to transesterification reactions lasting up to 6 h at conventional heating. The novel CMC esters represent biodegradable polymeric surfactants with potential applications in manufacture of consumer products and in industrial processes.

Similar content being viewed by others

References

Feddersen RL, Thorp SN (1993) Sodium carboxymethylcellulose. In: Whistler RL and BeMiller JA (ed) Industrial Gums, Polysaccharides and their Derivatives, Academic Press, San Diego New York Boston, 537

Vogt S, Klemm D, Heinze T (1996) Polym Bull 36:549

Heinze T, Dicke R, Koschella A, Kull A, Klohr EA, Koch W (2000) Macromol Chem Phys 201:627

Charpentier D, Mocanu G, Carpov A, Chapelle S, Merle L, Muller G (1997) Carbohydr Polym 33:177

Sroková I, Talaba P, Hodul P, Balažová A (1998) Tenside Surf Det 35:342

Cao Y, Li HL (2002) Eur Polym J 38:1457

Aburto J, Alric I, Borredon E (1999) Starch/Stärke 51:132

Vaca-Garcia C, Thiebaud S, Borredon ME, Gozzelino G (1998) J Am Oil Chem Soc 75:315

Vaca-Garcia C, Borredon ME (1999) Bioresource Technol 70:135

Neumannn U, Wiege B, Warwel S (2002) Starch/Stärke 54:449

Latetin AI, Gal’braikh LS, Rogovin ZA (1968) Polym Sci USSR 10:761

Rooney ML (1976) Polymer 17:555

Aburto J, Alric I, Borredon E (2005) Starch/Stärke 57:145

Mormann W, Al-Higari M (2004) Starch/Stärke 56:118

Žoldáková A, Sroková I, Sasinková V, Hirsch J, Ebringerová A (2005) Chem Pap 59:362

Skalková P, Sroková I, Sasinková V, Ebringerová A (2006) Tenside Surf Det 43:137

Sroková I, Tomanová V, Ebringerová A, Maloviková A, Heinze T (2004) Macromol Mater Eng 289:63

Galema SA (1997) Chemical Society Reviews 26:233

Koroskenyi B, McCarthy SP (2002) J Polym Environ 10:93

Bogdal D, Penczek P, Pielichowski J, Prociak A (2003) Adv Polym Sci 163:194

Gourson C, Benhaddou R, Granet R, Krausz P, Saulnier L, Thibault JF (1999) Compt Rend Ac Sci, Ser. IIc, Chim 2:75

Lewandowicz G, Fornal J, Walkowski A, Maczynski M, Urbaniak G, Szymanska G (2000) Industrial Crops and Products 11:249

Satgé C, Verneuil B, Branland P, Granet R, Krausz P, Rozier J, Petit C (2002) Carbohydr Polym 49:373

Antova G, Vasvasova P, Zlatanov M (2004) Carbohydr Polym 57:131

Sroková I, Čížová A, Sasinková V, Hromádková Z, Ebringerová A (2006) Micowave-assisted transesterification of O-(carboxymethyl)starch. In: Pielichowski K (ed) Modern Polymeric Materials for Environmental Applications, Wydavnictwo DjaF, Krakow, vol. 2, pp 31-36

Fang JM, Fowler PA, Tomkinson J, Hill CAS (2002) Carbohydr Polym 50:429

Hromádková Z, Kováčiková J, Ebringerová A (1999) Ind Crops Prod 9:101

Sroková I, Ebringerová A, Heinze T (2001) Tenside Surf Det 38:277

Stüpel H (1997) Synthetische Wasch-und Reinigungsmittel. 1st edition, Konradin Verlag, Stuttgart

Reuben J, Conner HT (1983) Carbohydr Res 115:1

Grote C, Heinze T (2005) Cellulose 12:435

Kamide K, Okajima K, Kowasaka K, Matsui M (1987) Polym J 19:1405

Singh V, Sethi R, Tewari A, Srivastava V, Sangh R (2003) Carbohydr Polym 54:523

Dickinson E (1988). The role of hydrocolloids in stability of particulate dispersions and emulsions. In: Philipps GO, Wedlock O J, Williams PH (ed) Gums and Stabilisers for the Food industry. IRL Press, Oxford, vol 4, pp. 249-263

Garti N, Leser ME (2001) Polym Adv Technol 12:123

Paik YH, Swift G (1995) Chem Ind 2:55

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tomanová, V., Pielichowski, K., Sroková, I. et al. Microwave-assisted synthesis of carboxymethylcellulose – based polymeric surfactants. Polym. Bull. 60, 15–25 (2008). https://doi.org/10.1007/s00289-007-0834-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-007-0834-1