Abstract

Clinching is a mechanical joining method using a simple toolset consisting of a punch, a die, and a blank holder. The shapes of these tools are the most important parameters that control the final geometry of the clinch joints and consequently the strength and quality of the latter. In order to save time and cost, these geometric parameters could be optimized by the use of finite element simulation. This paper reviews the published research related to the finite element modeling of the clinching process. In this study, a critical review of the latter had been carried out from different perspectives. The findings about difficulties facing the simulations of different clinching processes, the optimization of the process parameters, and the strength, joinability, and the quality of the joint were highlighted. In addition, future development, investigation, and more research are still needed to minimize problems and expenses in the industrial practical application of clinching.

Similar content being viewed by others

References

Deutsches Reichspatent DRP-No. 98517 (1897)

Kaščák L, Spišák E (2012) Clinching as a non-standard method for joining materials of dissimilar properties. Zesz Nauk Politechniki Rzeszowskiej Mech 84(3):31–41

Strandberg O, Lennblad J, L H (1994) FE modeling of the clinch joining process. In: Advanced technologies and processes IBEC:146–153

He X (2010) Recent development in finite element analysis of clinched joints. Int J Adv Manuf Technol 48(5–8):607–612

Varis J (2006) Economics of clinched joint compared to riveted joint and example of applying calculations to a volume product. J Mater Process Technol 172(1):130–138

Mucha J, Kaščák L, Spišák E (2011) Joining the car-body sheets using clinching process with various thickness and mechanical property arrangements. Arch Civil Mech Eng 11(1):135–148

Eshtayeh M, Hrairi M, Mohiuddin A (2015) Clinching process for joining dissimilar materials: state of the art. Int J Adv Manuf Technol:1–17. doi:DOI 10.1007/s00170-015-7363–0

Eshteyah M, Hrairi M, Dawood M, Mohiuddin A (2015) Finite element modeling of clinching process for joining dissimilar materials. Adv Mater Res 1115

Rietman B, Goretti Doig M, Weiher J (2001) Predicting the quality of clinch joints using FEM. Proc. of the 4th International ESAFORM Conference on Material Forming, Liege, Belgium, April 23–25, 2001, University de Liege, 597–600

Eckert A, Israel M, Neugebauer R, Rössinger M, Wahl M, Schulz F (2013) Local-global approach using experimental and/or simulated data to predict distortion caused by mechanical joining technologies. Prod Eng 7(2–3):339–349

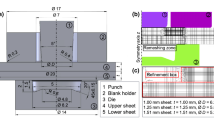

Hamel V, Roelandt J, Gacel J, Schmit F (2000) Finite element modeling of clinch forming with automatic remeshing. Comput Struct 77(2):185–200

Jayasekara V, Min KH, Noh JH, Kim MT, Seo JM, Lee HY, Hwang BB (2010) Rigid-plastic and elastic- plastic finite element analysis on the clinching joint process of thin metal sheets. Met Mater Int 16(2):339–347

Pietrapertosa C, Zhang L, Habraken A, Jaspart J-P (2003) Clinching joining system: validation of numerical models. In: 6th International ESAFORM Conference on Material Forming. Nuova Ipsa editire, pp 351–354

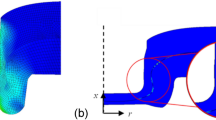

De Paula A, Aguilar M, Pertence A, Cetlin PR (2007) Finite element simulations of the clinch joining of metallic sheets. J Mater Process Technol 182(1):352–357

Coppieters S, Cooreman S, Lava P, Sol H, Van Houtte P, Debruyne D (2011) Reproducing the experimental pull-out and shear strength of clinched sheet metal connections using FEA. Int J Mater Form 4(4):429–440

Coppieters S, Cooreman S, Sol H, Debruyne D (2007) Reproducing the experimental strength of clinched connections with finite element methods. In: Proceedings of the SEM Annual Conference and Exposition on Experimental and Applied Mechanics. pp 572–579

Mucha J (2010) The characteristics of H320LA steel sheet clinching joints. Adv Manuf Sci Technol 34(4):47–61

Mucha J (2011) The analysis of lock forming mechanism in the clinching joint. Mater Des 32(10):4943–4954

Abe Y, Kishimoto M, Kato T, Mori K (2009) Joining of hot-dip coated steel sheets by mechanical clinching. Int J Mater Form 2(1):291–294

Lee C-J, Kim J-Y, Lee S-K, Ko D-C, Kim B-M (2010) Design of mechanical clinching tools for joining of aluminium alloy sheets. Mater Des 31(4):1854–1861

BOLLHOFF (2013) Devices and systems for joining sheets and profiles without fasteners. Accessed Accessed 02 May. 2015

Zheng JC, He XC, Xu JN, Zeng K, Ding YF, Hu YB (2012) Finite element analysis of energy saving jointing method base on energy materials: clinching. Adv Mater Res 577:9–12

Lambiase F, Di Ilio A (2013) Optimization of the clinching tools by means of integrated FE modeling and artificial intelligence techniques. Proc CIRP 12:163–168

Lambiase F, Di Ilio A (2013) Finite element analysis of material flow in mechanical clinching with extensible dies. J Mater Eng Perform 22(6):1629–1636

Lambiase F, Ilio AD, Paoletti A (2015) Joining aluminium alloys with reduced ductility by mechanical clinching. Int J Adv Manuf Technol 77:1295–1304

He X, Liu F, Xing B, Yang H, Wang Y, Gu F, Ball A (2014) Numerical and experimental investigations of extensible die clinching. Int J Adv Manuf Technol 74(9–12):1229–1236

He X, Zhao L, Yang H, Xing B, Wang Y, Deng C, Gu F, Ball A (2014) Investigations of strength and energy absorption of clinched joints. Comput Mater Sci 94:58–65

Gerstmann T, Awiszus B (2014) Recent developments in flat-clinching. Comput Mater Sci 81:39–44

Neugebauer R, Kraus C, Dietrich S (2008) Advances in mechanical joining of magnesium. CIRP Ann Manuf Technol 57(1):283–286

Neugebauer R, Todtermuschke M, Mauermann R, Riedel F (2008) Overview on the state of development and the application potential of dieless mechanical joining processes. Arch Civil Mech Eng 8(4):51–60

Han S, Wu Y, Gao Y, Zeng Q (2012) Study on clinching of magnesium alloy sheets with different lower die parameters based on DEFORM 2D. In: 2nd International Conference on Electronic & Mechanical Engineering and Information Technology, Atlantis Press

Lee C-J, Lee J-M, Ryu H-Y, Lee K-H, Kim B-M, Ko D-C (2014) Design of hole-clinching process for joining of dissimilar materials-Al6061-T4 alloy with DP780 steel, hot-pressed 22MnB5 steel, and carbon fiber reinforced plastic. J Mater Process Technol 214(10):2169–2178

Balawender T, Sadowski T, Kneć M (2011) Technological problems and experimental investigation of hybrid: clinched-adhesively bonded joint. Arch Metall Mater 56(2):438–446

Sadowski T, Balawender T (2011) Technology of clinch-adhesive joints. In: Hybrid Adhesive Joints. Springer, pp 149–176

Benabderrahmane B, Ali B (2013) Finite element analysis of the parameters affect the mechanical strength of a point clinched. In: International Journal of Engineering Research and Technology. vol 8 (August- 2013). ESRSA Publications

Benabderrahmane BA, Benzegaou (2012) Finite element modeling of the influence of clinch process parameters. Int J Sci Adv Technol 2(1):37–43

Israel M, Mauermann R, Schellnock J (2013) Thick sheet clinching. Advanced shipping and ocean engineering. Adv Shipping Ocean Eng 2(1):1–10

Jomaa M, Billardon R (2007) Numerical analysis of the resistance to pullout test of clinched assemblies of thin metal sheets. In: 10th ESAFORM Conference on Material Forming. vol 1. AIP Publishing, pp 169–174

Jomâa M, Billardon R (2007) Numerical analysis of the resistance to shear test of clinched assemblies of thin metal sheets. In: MATERIALS PROCESSING AND DESIGN; Modeling, Simulation and Applications; NUMIFORM’07; Proceedings of the 9th International Conference on Numerical Methods in Industrial Forming Processes. vol 1. AIP Publishing, pp 1123–1130

Saberi S, Enzinger N, Vallant R, Cerjak H, Hinterdorfer J, Rauch R (2008) Influence of plastic anisotropy on the mechanical behavior of clinched joint of different coated thin steel sheets. Int J Mater Form 1(1):273–276

Mori K, Abe Y, Kato T (2007) Finite element simulation of plastic joining processes of steel and aluminum alloy sheets. In: MATERIALS PROCESSING AND DESIGN; Modeling, Simulation and Applications; NUMIFORM’07; Proceedings of the 9th International Conference on Numerical Methods in Industrial Forming Processes. vol 1. AIP Publishing, pp 197–202

Kim H-K (2013) Fatigue strength evaluation of the clinched lap joints of a cold rolled mild steel sheet. J Mater Eng Perform 22(1):294–299

Coppieters S, Lava P, Sol H, Van Houtte P, Debruyne D (2013) Multi-axial quasi-static strength of a clinched sheet metal assembly. In: Experimental and Applied Mechanics, Volume 4. Springer, pp 339–344

Oudjene M, Ben‐Ayed L, Batoz JL (2007) Geometrical optimization of clinch forming process using the response surface method. In: MATERIALS PROCESSING AND DESIGN; Modeling, Simulation and Applications; NUMIFORM’07; Proceedings of the 9th International Conference on Numerical Methods in Industrial Forming Processes. vol 1. AIP Publishing, pp 531–536

Oudjene M, Ben-Ayed L (2008) On the parametrical study of clinch joining of metallic sheets using the Taguchi method. Eng Struct 30(6):1782–1788

Oudjene M, Ben-Ayed L, Delameziere A, Batoz J-L (2009) Shape optimization of clinching tools using the response surface methodology with Moving Least-Square approximation. J Mater Process Technol 209(1):289–296

Roux E, Bouchard P-O (2013) Kriging metamodel global optimization of clinching joining processes accounting for ductile damage. J Mater Process Technol 213(7):1038–1047

Zhao S, Xu F, Guo J, Han X (2014) Experimental and numerical research for the failure behavior of the clinched joint using modified Rousselier model. J Mater Process Technol 214(10):2134–2145

Wen T, Wang H, Yang C, Liu LT (2014) On a reshaping method of clinched joints to reduce the protrusion height. Int J Adv Manuf Technol 71(9–12):1709–1715

Abe Y, Kato T, Mori K (2007) Joining of aluminium alloy and mild steel sheets using mechanical clinching. In: Materials Science Forum. Trans Tech Publ, pp 1043–1046

Abe Y, Mori K, Kato T (2012) Joining of high strength steel and aluminium alloy sheets by mechanical clinching with dies for control of metal flow. J Mater Process Technol 212(4):884–889

Lee C-J, Kim J-Y, Lee S-K, Ko D-C, Kim B-M (2010) Parametric study on mechanical clinching process for joining aluminum alloy and high-strength steel sheets. J Mech Sci Technol 24(1):123–126

Markowski T, Mucha J, Witkowski W (2013) FEM analysis of clinching joint machine’s C-frame rigidity. Eksploatacja Niezawodność 15:51–57

Gao Y, Liu Z-X, Wang P-C (2014) Effect of aging on the strength of clinching galvanized SAE1004 steel-to-aluminum AA6111 joints. J Manuf Sci Eng 136(4):041016

Mucha J, Spišák E (2013) The experimental analysis of forming and strength of clinch riveting sheet metal joint made of different materials. Adv Mech Eng 5:848973

He X, Zhang Y, Xing B, Gu F, Ball A (2015) Mechanical properties of extensible die clinched joints in titanium sheet materials. Mater Des 71:26–35

Mucha J, Kaščák L, Spišák E (2015) The experimental analysis of cold pressed joint technology for selected sheet metals used in an automotive industry. Adv Mater Res 1077:33–38

Mucha J, Witkowski W (2014) The clinching joints strength analysis in the aspects of changes in the forming technology and load conditions. Thin-Walled Struct 82:55–66

Lambiase F, Di Ilio A (2014) An experimental study on clinched joints realized with different dies. Thin-Walled Struct 85:71–80

Jiang T, Liu Z-X, Wang P-C (2015) Effect of aluminum pre-straining on strength of clinched galvanized SAE1004 steel-to-AA6111-T4 aluminum. J Mater Process Technol 215:193–204

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Eshtayeh, M.M., Hrairi, M. Recent and future development of the application of finite element analysis in clinching process. Int J Adv Manuf Technol 84, 2589–2608 (2016). https://doi.org/10.1007/s00170-015-7781-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-7781-z