Abstract

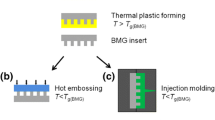

A novel process chain for serial production of polymer-based devices incorporating both micro- and nano-scale features is proposed. The process chain is enabled by the use of Zr-based bulk metallic glasses (BMG) to achieve the necessary level of compatibility and complementarity between its component technologies. It integrates two different technologies, namely laser ablation and focused ion beam (FIB) milling for micro-structuring and sub-micron patterning, respectively, thus to fabricate inserts incorporating different length scale functional features. Two alternative laser sources, namely nano-second (NS) and pico-second (PS) lasers, were considered as potential candidates for the first step in this master-making process chain. The capabilities of the component technologies together with some issues associated with their integration were studied. To validate the replication performance of the produced masters, a Zr-based BMG insert was used to produce a small batch of micro-fluidic devices by micro-injection moulding. Furthermore, an experimental study was also carried out to determine whether it would be possible by NS laser ablation to structure the Zr-based BMG workpieces with a high surface integrity whilst retaining the BMG’s non-crystalline morphology. Collectively, it was demonstrated that the proposed process chain could be a viable fabrication route for mass production of polymer devices incorporating different length scale features.

Similar content being viewed by others

References

(HLG) H.L.E.G (2011) Key enabling technologies—final report. European Commission. Retrieved from http://ec.europa.eu/enterprise/sectors/ict/files/kets/hlg_report_final_en.pdf

Attia UM, Marson S, Alcock JR (2009) Micro-injection moulding of polymer microfluidic devices. Microfluid Nanofluid 7(1):1–28. doi:10.1007/s10404-009-0421-x

Bigot S, Minev R, Dimov SS, Dobrev T (2011) Function and length scale integration in innovative products—technical solutions and new organisational models. Int J Manuf Technol Manag 23(3/4):157–178

Bonse J, Kruger J, Hohm S, Rosenfeld A (2012) Femtosecond laser-induced periodic surface structures. J Laser Appl 24:4207–42006

Brousseau EB, Dimov SS, Pham DT (2010) Some recent advances in multi-material micro- and nano-manufacturing. Int J Adv Manuf Technol 47(1–4):161–180

Chen C-Y, Chung C-J, Wu B-H, Li W-L, Chien C-W, Wu P-H, Cheng C-W (2012) Microstructure and lubricating property of ultra-fast laser pulse textured silicon carbide seals. Appl Phys A 107(2):345–350. doi:10.1007/s00339-012-6822-9

Clark W, Horrell K, Rogelstad T, Spagon P (1995) SEMATECH qualification plan guidelines for engineering. SEMATECH Inc

Dimov SS, Brousseau EB, Minev R, Bigot S (2012) Micro- and nano-manufacturing: challenges and opportunities. Proc Inst Mech Eng C J Mech Eng Sci 226(3):3–15

Dobrev T, Dimov SS, Thomas AJ (2006) Laser milling: modelling crater and surface formation. Proc Inst Mech Eng C J Mech Eng Sci 220(11):1685–1696. doi:10.1243/09544062jmes221

Dobrev, T., Pham, D. T., & Dimov, S. S. (2005). A simulation model for crater formation in laser milling. In W. Menz & S. S. Dimov (Eds.), 4M 2005 First International Conference on Multi-Material Manufacture Proceedings (pp. 155–159). Karlsruhe: Elsevier

Etsion I (2005) State of the art in laser surface texturing. Trans ASME J Tribol 127(1):248–253

Fadeeva E, Truong VK, Stiesch M, Chichkov BN, Crawford RJ, Wang J, Ivanova EP (2011) Bacterial retention on superhydrophobic titanium surfaces fabricated by femtosecond laser ablation. Langmuir 27(6):3012–3019. doi:10.1021/la104607g

Fleischer J, Kotschenreuther J (2007) The manufacturing of micro molds by conventional and energy-assisted processes. Int J Adv Manuf Technol 33(1–2):75–85. doi:10.1007/s00170-006-0596-1

Giboz J, Copponnex T, Mele P (2007) Microinjection moulding of thermoplastic polymers—a review. J Micromech Microeng 17(6):R96–R109

Griffiths CA, Dimov SS, Brousseau EB, Hoyle RT (2007) The effects of tool surface quality in micro-injection moulding. J Mater Process Technol 189(1–3):418–427

Heckele M, Schomburg WK (2004) Review on micro molding of thermoplastic polymers. J Micromech Microeng 14(3):R1–R14. doi:10.1088/0960-1317/14/3/R01

Huang CK (2007) Polymeric nanofeatures of 100 nm using injection moulding for replication. J Micromech Microeng 17(8):1518–1526

Inoue A (2000) Stabilization of metallic supercooled liquid and bulk amorphous alloys. Acta Mater 48:278–306

ISO 4288 (1997) Geometrical product specifications (GPS)—surface texture: profile method—rules and procedures for the assessment of surface texture

Joint Committee for Guides in Metrology (JCGM) (2008) Evaluation of measurement data—guide to the expression of uncertainty in measurement (GUM) (p. 121)

Kawasegi N, Morita N, Yamada S, Takano N, Oyama T, Ashida K, Ofune H (2006) Rapid nanopatterning of a Zr-based metallic glass surface utilizing focused ion beam induced selective etching. Appl Phys Lett 89(14):143115–1431153

Kirkup L, Frenkel B (2006) An introduction to uncertainty in measurement (first). Cambridge University Press

Knowles M, Kearsley A, Karnakis D (2007) Industrial lasers: laser micromachining expands as technology develops. Laser Focus World. PennWell Corporation/Technology Group. Retrieved from http://www.laserfocusworld.com/articles/print/volume-43/issue-6/features/industrial-lasers-laser-micromachining-expands-as-technology-develops.html

Knowles MRH, Rutterford G, Karnakis D, Ferguson A (2007) Micro-machining of metals, ceramics and polymers using nanosecond lasers. Int J Adv Manuf Technol 33(1–2):95–102. doi:10.1007/s00170-007-0967-2

Kumar G, Schroers J (2008) Write and erase mechanisms for bulk metallic glass. Appl Phys Lett 92(3):31901–31903. doi:10.1063/1.2834712

Lalev G, Dimov SS, Kettle J, Van Delft F, Minev R (2008) Data preparation for FIB machining of complex 3D structures. Proc Inst Mech Eng B J Eng Manuf 222(1):67–76

Lalev G, Petkov P, Sykes N, Hirshy H, Velkova V, Dimov S, Barrow D (2009) Fabrication and validation of fused silica NIL templates incorporating different length scale features. Microelectron Eng 86(4–6):705–708. doi:10.1016/j.mee.2009.01.074

Leach, RK (2001) Measurement good practice guide no. 37—the measurement of surface texture using stylus instruments. (N.P. Laboratory, Ed.)

Li W, Minev R, Dimov SS, Lalev G (2007) Patterning of amorphous and polycrystalline Ni78B14Si8 with a focused ion beam. Appl Surf Sci 253(12):5404–5410

Lin H-K, Lee C-J, Hu T-T, Li C-H, Huang JC (2012) Pulsed laser micromachining of Mg-Cu-Gd bulk metallic glass. Opt Lasers Eng 50(6):883–886. doi:10.1016/j.optlaseng.2012.01.003

Loffler JF, Kundig AA, Dalla Torre FH (2007) Rapid solidification and bulk metallic glasses—processing and properties. In J. R. Groza, J. F. Shackelford, E. J. Lavernia, & M. T. Powers (Eds.), Materials Processing Handbook (pp. 17–44). CRC Press

Minev R, Ilieva M, Kettle J, Lalev G, Dimov SS, Tzaneva D, Shishkov R (2010) Deposition and FIB milling of anticorrosive CrC coatings on tool steel substrates. Int J Adv Manuf Technol 47(1–4):29–35. doi:10.1007/s00170-009-2078-8

Minev, R., Vella, P. C., Brousseau, E. B., Dimov, S. S., Minev, E., & Matthews, C. W. (2010). Methodology for capability maturity assessment of MNT chains. In B. Fillon, C. Khan-Malek, & S. S. Dimov (Eds.), 7th International Conference on Multi-Material Micro Manufacture (pp. 249–252). Bourg en Bresse and Onayonnax, France: Research Publishing

Minev, R., Vella, P. C., Brousseau, E. B., Dimov, S. S., Scholz, S., & Matthews, C. W. (2010). Capability maturity study of the horizontal and vertical integration of structuring, patterning and characterization of MNTs. In B. Fillon, C. Khan-Malek, & S. S. Dimov (Eds.), 7th International Conference on Multi-Material Micro Manufacture (pp. 253–256). Bourg en Bresse and Oyonnax, France: Research Publishing

Monkkonen K, Hietala J, Paakkonen P, Paakkonen EJ, Kaikuranta T, Pakkanen TT, Jaaskelainen T (2002) Replication of sub-micron features using amorphous thermoplastics. Polym Eng Sci 42(7):1600–1608

Montgomery DC (2009) Design and analysis of experiments (7th edition, p. 656). John Wiley & Sons Inc

Nayak BK, Gupta MC (2010) Self-organized micro/nano structures in metal surfaces by ultrafast laser irradiation. Opt Lasers Eng 48(10):940–949. doi:10.1016/j.optlaseng.2010.04.010

Packard CE, Schroers J, Schuh CA (2009) In situ measurements of surface tension-driven shape recovery in a metallic glass. Scr Mater 60(12):1145–1148. doi:10.1016/j.scriptamat.2009.02.056

Petkov PV, Dimov SS, Minev RM, Pham DT (2008) Laser milling: pulse duration effects on surface integrity. Proc Inst Mech Eng B J Eng Manuf 222(1):35–45. doi:10.1243/09544054jem840

Petkov, P. V, Scholz, S., & Dimov, S. S. (2008). Strategies for material removal in laser milling. In S. S. Dimov & W. Menz (Eds.), 4M 2008—Fourth International Conference on Multi-Material Micro Manufacture Proceedings (pp. 249–252). Cardiff, Wales, UK: Whittles Publishing

Pham DT, Dimov SS, Ji C, Petkov PV, Dobrev T (2004) Laser milling as a rapid micromanufacturing process. Proc Inst Mech Eng B J Eng Manuf 218:1–7

Pham DT, Dimov SS, Petkov PV (2007) Laser milling of ceramic components. Int J Mach Tool Manuf 47:618–626

Platzgummer E, Loeschner H, Gross G (2008) Projection maskless patterning for nanotechnology applications. In 52nd International Conference on Electron, Ion and Photon Beam Technology and Nanofabrication (pp. 2059–2063). AVS

Quintana I, Dobrev T, Aranzabe A, Lalev G, Dimov SS (2009) Investigation of amorphous and crystalline Ni alloys response to machining with micro-second and pico-second lasers. Appl Surf Sci 255(13–14):6641–6646

Scholz SG, Griffiths C a, Dimov SS, Brousseau EB, Lalev G, Petkov P (2011) Manufacturing routes for replicating micro and nano surface structures with bio-mimetic applications. CIRP J Manuf Sci Technol 4(4):347–356. doi:10.1016/j.cirpj.2011.05.004

Scholz S, Griffiths CA, Dimov SS, Brousseau EB, Lalev G, Petkov PV (2009) New process chains for replicating micro and nano structured surfaces with bio-mimetic applications. In ANTEC 2009—Proceedings of the 67th Annual Technical Conference & Exhibition (pp. 3021–3027). Chicago

Sha B, Dimov S, Griffiths C, Packianather MS (2006) Micro-injection moulding: factors affecting the achievable aspect ratios. Int J Adv Manuf Technol 33(1–2):147–156. doi:10.1007/s00170-006-0579-2

Svintsov A, Zaitsev S, Lalev G, Dimov SS, Velkova V, Hirshy H (2009) FIB sputtering optimization using Ion Reverse Software. Microelectron Eng 86(4–6):544–547. doi:10.1016/j.mee.2009.01.073

Tosello G (2008) Precision moulding of polymer micro components—optimisation, simulation, tooling, quality control and multi-material application. DTU

Tosello G, Bissacco G, Tang PT, Hansen HN, Nielsen PC (2008) High aspect ratio micro tool manufacturing for polymer replication using μEDM of silicon, selective etching and electroforming. Microsyst Technol 14(9–11):1757–1764

Tosello G, Chiffre L. De (2004) Standard traceability and measurement uncertainty (p. 116)

Tosello G, Gava A, Hansen HN, Lucchetta G (2010) Study of process parameters effect on the filling phase of micro-injection moulding using weld lines as flow markers. Int J Adv Manuf Technol 47:81–97

Tosello G, Hansen HN, Gasparin S (2009) Applications of dimensional micro metrology to the product and process quality control in manufacturing of precision polymer micro components. CIRP Ann Manuf Technol 58(1):467–472. doi:10.1016/j.cirp.2009.03.027

Tosello G, Marinello F, Hansen HN (2012) Characterisation and analysis of microchannels and submicrometre surface roughness of injection moulded microfluidic systems using optical metrology. Plast Rubber Compos 41(1):29–39. doi:10.1179/0743289811Y.0000000017

United Kingdom Accreditation Service (UKAS) (2007) The expression of uncertainty and confidence in measurement (Vol. 44, pp. 1–82)

Uriarte L, Herrero A, Ivanov A, Oosterling H, Staemmler L, Tang PT, Allen D (2006) Comparison between microfabrication technologies for metal tooling. Proc Inst Mech Eng C J Mech Eng Sci 220(11):1665–1676. doi:10.1243/09544062JMES220

Vehse M, Lobler M, Schmitz KP, Seitz H (2012) Laser induced surface structure on stainless steel influences cell viability. Biomed Tech 57(Suppl 1):419–421

Velkova V (2011) Focused ion beam technology: implementation in manufacturing platforms and process optimisation. Manufacturing Engineering Centre, School of Engineering, Cardiff University, Cardiff

Velkova V, Lalev G, Hirshy H, Omar F, Scholz S, Minev E, Dimov S (2011) Process chain for serial manufacture of 3D micro- and nano-scale structures. CIRP J Manuf Sci Technol 4(4):340–346. doi:10.1016/j.cirpj.2011.03.005

Velkova V, Lalev G, Hirshy H, Scholz S, Hiitola-Keinänen J, Gold H, Dimov S (2010) Design and validation of a novel master-making process chain for organic and large area electronics on flexible substrates. Microelectron Eng 87(11):2139–2145. doi:10.1016/j.mee.2010.01.015

Vella PC, Brousseau EB, Minev R, Dimov SS (2010) A methodology for technology maturity assessment of micro and nano manufacturing processes and process chains. In F. E. Pfefferkorn (Ed.), The 5th International Conference on MicroManufacturing (ICOMM/4M 2010) (pp. 327–334). Madison, Wisconsin, USA

Wang X, Lu P, Dai N, Li Y, Liao C, Zheng Q, Liu L (2007) Noncrystalline micromachining of amorphous alloys using femtosecond laser pulses. Mater Lett 61(21):4290–4293

Waniuk T, Schroers J, Johnson WL (2003) Timescales of crystallization and viscous flow of the bulk glass-forming Zr-Ti-Ni-Cu-Be alloys. Phys Rev B 67(18):184203–184209. doi:10.1103/PhysRevB.67.184203

Wu B, Ozel T (2011) Micro-laser processing. In M. Koc & T. Ozel (Eds.), Micro-manufacturing—design and manufacturing of micro-products (First., pp. 159–195). Wiley

Wu PH, Cheng CW, Chang CP, Wu TM, Wang JK (2011) Fabrication of large-area hydrophobic surfaces with femtosecond-laser-structured molds. J Micromech Microeng 21(11):115032

Youn SW, Takahashi M, Goto H, Maeda R (2006) Microstructuring of glassy carbon mold for glass embossing—comparison of focused ion beam, nano/femtosecond-pulsed laser and mechanical machining. Microelectron Eng 83(11–12):2482–2492. doi:10.1016/j.mee.2006.05.007

Zhang G, Liu Y, Zhang B (2006) Effect of annealing close to Tg on notch fracture toughness of Pd-based thin-film metallic glass for MEMS applications. Scr Mater 54(5):897–901

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Vella, P.C., Dimov, S.S., Brousseau, E. et al. A new process chain for producing bulk metallic glass replication masters with micro- and nano-scale features. Int J Adv Manuf Technol 76, 523–543 (2015). https://doi.org/10.1007/s00170-014-6148-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-014-6148-1