Abstract

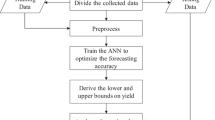

We propose a cost estimation model based on a fuzzy rule backpropagation network, configuring the rules to estimate the cost under uncertainty. A multiple linear regression analysis is applied to analyze the rules and identify the effective rules for cost estimation. Then, using a dynamic programming approach, we determine the optimal path of the manufacturing network. Finally, an application of this model is illustrated through a numerical example showing the effectiveness of the proposed model for solving the cost estimation problem under uncertainty.

Similar content being viewed by others

References

Abdi H, Valentin D, Edelman B, O’Toole AJ (1996) A Widrow–Hoff learning rule for a generalization of the linear auto-associator. J Math Psychol 40:175–182

Bellman R (1957) Dynamic programming. Princeton University Press, Princeton

Bellman R (2003) Dynamic programming. Dover Publications, New York

Ben-Arieh D, Qian L (2003) Activity-based cost management for design and development stage. Int J Prod Econ 83:169–183

Cavalieria S, Maccarroneb P, Pinto R (2004) Parametric vs. neural network models for the estimation of production costs: a case study in the automotive industry. Int J Prod Econ 91:165–177

Cheng B, Titterington DM (1994) Neural networks: a review from a statistical perspective. Stat Sci 9(1):2–30

Dai JB, Lee NKS (2012) Economic feasibility analysis of flexible material handling systems: a case study in the apparel industry. Int J Prod Econ 136(1):28–36

Deng S, Yeh T-H (2011) Using least squares support vector machines for the airframe structures manufacturing cost estimation. Int J Prod Econ 131(2):701–708

Dreyfus SE, Law AM (1977) The art and theory of dynamic programming. Academic, New York

Dvir D, Ben-Davidb A, Sadehb A, Shenhar AJ (2006) Critical managerial factors affecting defense projects success: a comparison between neural network and regression analysis. Eng Appl Artif Intel 19:535–543

Feng C-X, Wang V (2002) Surface roughness predictive modeling: neural networks versus regression. IIE Trans Des Manuf 40(3):683–697

Feng C-X, Wang X (2002) Digitizing uncertainty modeling for reverse engineering applications: regression versus neural networks. J Intell Manuf 13(3):189–199

Finnie GR, Wittig GE, Desharnais J-M (1997) A comparison of software effort estimation techniques: using function points with neural networks, case-based reasoning and regression models. J Syst Softw 39(3):281–289

Gallinari P, Thiria S, Badran F, Fogelman-Soulie F (1991) On the relations between discriminant analysis and multilayer perceptrons. Neural Netw 4(3):349–360

Gayretli A, Abdalla HS (1999) A featured based prototype system for the evaluation and optimization of manufacturing processes. Comput Ind Eng 37:481–484

Ghasemzadeh S, Behrangi E, Azgomi MA (2009) Conflict-free scheduling and routing of automated guided vehicles in mesh topologies. Robot Auton Syst 30:738–748

Heiat A (2002) Comparison of artificial neural network and regression models for estimating software development effort. Inf Softw Technol 44(15):911–922

Ibaraki T (1987) Enumerative approaches to combinatorial optimization—part II. Ann Oper Res 11:397–439

Khayat GE, Lagevin A, Riopel D (2006) Integrated production and material handling scheduling using mathematical programming and constraint programming. Eur J Oper Res 175:1818–1832

Kim G-H, An S-H, Kang K-I (2004) Comparison of construction cost estimating models based on regression analysis, neural networks, and case-based reasoning. Build Environ 39(10):1235–1242

Klir GJ, Yuan B (1995) Fuzzy sets and fuzzy logic: theory and applications. Prentice-Hall, US

Krishnaswamy M, Krishnan P (2002) Nozzle wear rate prediction using regression and neural network. Biosyst Eng 82(1):53–64

Lee J, Um K (2000) A comparison in a back-bead prediction of gas metal arc welding using multiple regression analysis and artificial neural network. Opt Lasers Eng 34(3):149–158

Marsten RE, Morin TL (1978) A hybrid approach to discrete mathematical programming. Math Program 14:21–40

Martello S, Pisinger D, Toth P (1999) New trends in exact algorithms for the 0–1 knapsack problem. Eur J Oper Res 123:325–336

McKim RA (1993) Neural network applications to cost engineering. Cost Eng 35:31–35

Niazi A, Dai JS, Balabani S, Seneviratne L (2006) Product cost estimation: technique classification and methodology review. J Manuf Sci Eng 128:563–575

Nolan A (1998) An intelligent system for case review and risk assessment in social services. AI Mag 19(1):39–46

Pendharkar PC (2006) Scale economies and production function estimation for object-oriented software component and source code documentation size. Eur J Oper Res 172:1040–1050

Plateau G, Elkihel M (1985) A hybrid method for the 0–1 knapsack problem. Meth Oper Res 49:277–293

Quintana G, Ciurana J (2011) Cost estimation support tool for vertical high speed machines based on product characteristics and productivity requirements. Int J Prod Econ 134(1):188–195

Rehman S, Guenov MD (1998) A methodology for modeling manufacturing costs at conceptual design. Comput Ind Eng 35:623–626

Ripley BD (1994) Neural networks and related methods for classification. J Roy Stat Soc B (Methodological) 56(3):409–456

Roy R, Souchoroukov P, Shehab E (2011) Detailed cost estimating in the automotive industry: data and information requirements. Int J Prod Econ 133(2):694–707

Sarle WS (1994) Neural networks and statistical models. In Proceedings of the 19th annual SAS users group international conference, pp. 215–221

Schumacher M, Robner R, Vach W (1996) Neural networks and logistic regression: part I. Comput Stat Data Anal 21(6):661–682

Setyawati BR, Sahirman S, Creese RC (2002) Neural networks for cost estimation. AACE Int Trans EST13:13.1–13.8

Shehab EM, Abdalla HS (2001) Manufacturing cost modeling for concurrent product development. Robot Comput Integrated Manuf 17:341–353

Shuhui L, Wunsch DC, O’Hair E, Giesselmann MG (2001) Comparative analysis of regression and artificial neural network models for wind turbine power curve estimation. J Sol Energ Eng 123:327–332

Smith AE, Mason AK (1997) Cost estimation predictive modeling: regression versus neural network. Eng Econ 42(2):137–161

Toth P (1980) Dynamic programming algorithms for the zero–one knapsack problem. Computing 25:29–45

Turban E, Aronson J (1998) Decision support systems and intelligent systems. Prentice-Hall, London

Vach W, Robner R, Schumacher M (1996) Neural networks and logistic regression: part II. Comput Stat Data Anal 21(6):683–701

Vis IFA (2006) Survey of research in the design and control of automated guided vehicle systems. Eur J Oper Res 170:677–709

Vrbsky SV (1997) A data model for approximate query processing of real time database. Data Knowl Eng 21:79–102

Warner B, Misra M (1996) Understanding neural networks as statistical tools. Am Stat 50(4):284–293

Weiss N, Kulikowski I (1991) Computer systems that learn. Morgan- Kaufman, California

Wu N, Zhou M (2005) Modeling and deadlock avoidance of automated manufacturing systems with multiple automated guided vehicles. IEEE Trans Syst Man Cybern B 35:1193–1201

Yang CO, Lin TS (1997) Developing an integrated framework for feature-based early manufacturing cost estimation. Int J Adv Manuf Technol 13:618–629

Yesilnacar E, Topal T (2005) Landslide susceptibility mapping: a comparison of logistic regression and neural networks methods in a medium scale study, Hendek region (Turkey). Eng Geol 79(3–4):251–266

Zhengrong G, Lam LH, Dhurjati PS (1996) Feature correlation method for enhancing fermentation development: a comparison of quadratic regression with artificial neural networks. Comput Chem Eng 20(Supp 1):S407–S412

Zimmermann HJ (1996) Fuzzy set theory and its applications, 3rd edn. Kluwer Academic, Boston

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fazlollahtabar, H., Mahdavi-Amiri, N. Design of a neuro-fuzzy–regression expert system to estimate cost in a flexible jobshop automated manufacturing system. Int J Adv Manuf Technol 67, 1809–1823 (2013). https://doi.org/10.1007/s00170-012-4610-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-012-4610-5