Abstract

This paper focuses on identifying the reasons for change propagation during the production phase of the product life cycle. Unlike the traditional change propagation study where the focus is within the product, this study is focused to understand the propagation effects of change on other functional silos in the manufacturing firm. First, the reasons for the changes are identified using archival analysis through which it is found that 77.0 % of changes are due to internal reasons while 23.0 % are external. Second, these changes are distinguished into genesis, and propagated changes using a matrix-based modeling approach from which the reasons for propagation are identified. It is inferred that 32.4 % of the total changes are due to propagated changes such as inventory issues, manufacturing issues, and design error rectification. The majority of reasons for these propagated changes include document error rectification such as BOM error, drawing error, incorrect introduction date in engineering change note, and design error rectification such as design limitations. The findings indicate nearly one-third of time spent by the engineers can be reduced by developing appropriate controls during the change release process.

Similar content being viewed by others

1 Engineering change

The global competition in the market place for products motivates engineering firms to develop products with improved performance and quality at lower costs. As a result, product development involves a steady evolution of the designed artifact as the parts are continuously changed before and during the course of production (Clarkson et al. 2004; Eckert et al. 2003; Duhovnik and Tavcar 2002). These changes are termed “engineering changes” (ECs) but assigned definitions by different authors with subtle differences (Jarratt et al. 2005). In this research, engineering change is defined in a comprehensive manner to encompass the content of other definitions by other researchers (Clark and Fujimoto 1991; Loch and Terwiesch 1999; Wright 1997).

Specifically the authors define an engineering change as:

An engineering change is an alteration made to parts, from embodiment design stage through production stage of the product life cycle, in its form or fit or function, drawings or software that has already been released. The change can be of any size or type, can involve any number of people, and can take any length of time.

In this definition, the engineering changes that occur during conceptual design phase are not included because they are not documented for the purpose of communicating to other departments in the manufacturing firm. For instance, an abstract concept is not necessary to be shared with the tooling department or logistics. As the concept matures from abstract to concrete level, it is then essential to formally document the design, such as drawing, and communicate with other departments for them to initiate action, such as tool and supplier development. Therefore, the above definition includes changes only from the embodiment design phase in which the products assume the appropriate form and fit (Pahl et al. 2007).

ECs are also described using different terms such as “design changes” (Ollinger and Stahovich 2001; Rouibah and Kevin 2003), “product design changes” (Huang and Johnstone 1995), and “product change” (Innes 1994), all of which refer to the same concept (Jarratt et al. 2005). In this research, the term “engineering change” (EC) or “change” is used for simplicity. Changes are classified into initiated and emergent changes; initiated changes are changes due to new needs while emergent changes are responses to the product weaknesses (Eckert et al. 2004).

1.1 Change propagation

Change propagation, a phenomenon by which one change initiates a series of other changes (Clarkson et al. 2004), can potentially disrupt the manufacturing process (Williams 1983). This change propagation appears as cause–effect–cause–effect patterns, whereby the dependent variable, or effect, at an earlier stage becomes the independent variable, or cause, for the subsequent stage. A concern identified in the product as a result of an engineering change, EC1 in Fig. 1, manifests itself into a cause for a propagated change (EC2), which can result in a series of other changes.

In a complex system, the components are connected through linking parameters such as geometry, material, function, and behavior. Thus, changing any one of these parameters may necessitate change in several other parameters within the system (Eckert et al. 2001, 2004). For example, in complex systems such as automobiles, a change in the engine may necessitate another change in the braking system. It should be noted that part interconnectedness is oftentimes used as a measure of system complexity (Matheison and Summers 2010; Summers and Shah 2003; Ameri et al. 2008).

Change propagation has been studied with a premise that direct or indirect linking parameters between the components of the system are considered the fundamental cause (Giffin 2007). However, changes can affect other departments in the manufacturing firm that are not directly concerned with these parameters. For example, a change of material can lead to breakage of the cutting tool during manufacturing; a change in the length of the part can lead to a change in the dimensions of the packaging box; a change from drum brake to disk brake in a heavy commercial vehicle can render the hydraulic lift in the assembly line with insufficient grab force. Thus, a change propagation phenomenon is not limited to the linking design parameters due to the part interconnectedness, but also due to the parameters connecting different departments within the organization. This fact is corroborated from the results of an industrial case study showing that a requirement change may affect other changes, but not necessarily directly through shared parameters (Morkos and Summers 2010). Therefore, it is essential to study this phenomenon by enhancing the scope of change propagation from its traditional product domain to across the different functional silos in the manufacturing firm because of the detrimental effects discussed in the next section.

1.2 Detrimental effects of ECs

As several industrial studies have shown, the effects of ECs may be detrimental to a company in terms of the lead time of the product, the cost involved, and the human resources allocated (Huang and Mak 1999; Maull et al. 1992; Boznak and Decker 1993; Kidd and Thompson 2000; Watts 1984a; Clark and Fujimoto 1991). The average time necessary for implementing an EC is 120 days; 40 days to design and develop, 40 days to process, and 40 days to implement in production (Rouibah and Kevin 2003; Watts 1984a). The use of Internet-based engineering change management systems (ECM) (Huang et al. 2001) has the potential to reduce the 40 days needed to process an EC. However, the 80 days to implement the design and production changes can still significantly affect the product lead time.

A change issued early in the development process is associated with minimal investments in tooling, validation, manufacturing processes, and equipment. These investments increase successively as the design moves toward maturity for full-scale production, the cost of an EC in each successive phase within the product life cycle being ten times more than the previous phase (Jarratt et al. 2006). In addition to the time and cost, nearly one-third to one-half of the human resource associated with product development is required to manage the ECs (Terwiesch and Loch 1999; Soderberg 1989). Thus, suitable control must be developed to reduce the propagated changes during the production phase as it tends to be the most expensive. However, it is first necessary to determine the reasons for these changes.

2 Research questions on ECs in production phase

In the context of incremental product design, the lack of fundamental understanding in ECs is emphasized (Wright 1997). Specifically, studies of the impact of ECs on manufacturing in European companies revealed the need to develop guidelines for managing the EC process to support incremental product design (Pikosz and Malmqvist 1998; Huang and Mak 1999). In another study, the detrimental effects of ECs on the product lead time emphasize the necessity for developing approaches to effectively manage the engineering change processes (Terwiesch and Loch 1999). In order to manage these changes, the reasons for such changes were studied from a managerial perspective and strategies to deal with them were proposed (Fricke et al. 2000; Eckert et al. 2003). Though the reasons for change propagation through component interconnectedness was also undertaken in a subsequent study (Jarratt et al. 2006), limited studies have been undertaken so far to determine the reasons for changes in the production phase of the product life cycle (Ahmed and Kanike 2007; Vianello and Ahmed 2008) and reasons for propagation from non-part interconnectedness, that is, how an EC could affect different functional silos in the manufacturing firm, thereby leading to subsequent changes. Therefore, to address this gap, the authors pursued two research questions:

- RQ1:

-

What are the reasons for engineering changes, in a manufacturing firm, in the production phase of the product life cycle?

- RQ2:

-

What are the reasons for propagation due to non-part interconnectedness?

This paper is organized as follows: the proposed research method is detailed in Sect. 3; the findings for the first research question are detailed in Sect. 4; the data collection process to explore second research question is described in Sect. 5; the findings for the second research question are elucidated in Sect. 6, followed by a note on validity of this research in Sect. 7, with conclusions in Sect. 8.

3 Research method

The research reported in this paper uses case study research method applied in an automotive original equipment manufacturer (OEM) to address these research questions. This OEM was selected using the criteria of the specific product manufactured, which are complex large road vehicles requiring a great degree of product customization. Studying such a complex system will enable researchers to explore change propagation phenomenon; hence, the findings may be generalized to a less complex products.

The authors undertook case study research as it is widely employed in engineering design research to investigate contemporary phenomena in uncontrolled environments to study complex topics and interactions between topics (Roth 1999; Flyvbjerg 2004; Sheldon 2006; Stowe 2008; Frost 1999; Teegavarapu et al. 2008; George and Bennett 2005).

The author Prabhu Shankar of this paper worked as a graduate design intern for 8 months in the engineering design department of this OEM, which was selected as it has the sole authority to control all decisions regarding engineering changes. The product development and support group work collaboratively to ensure the smooth production of these large road vehicles. The change requests are received by the support group and processed subsequently in consultation with the development group on an as-need basis.

To explore the first research question, archival records are used for data collection, which are primarily the engineering change notice forms (see Sect. 3.1). To explore the second research question, the reasons identified from these records are differentiated into genesis and propagated change. The potential reasons for propagated changes are subsequently identified through the development of an interaction model of the cause–effect pattern of ECs from the data obtained through focused interviews.

Prior to the discussion of data collection, an overview of the investigation site, their engineering change data management, and their engineering change process to handle emergent changes in the production phase is presented in the following section.

3.1 Overview of the investigation site

The OEM, located in the central part of the United States, manufactures large road vehicles by making use of both in-house manufactured parts and parts from its large network of suppliers. The manufacturing plant is a non-automated factory that produces some sixty vehicles daily using such conventional manufacturing processes as arc welding, spot welding, simple tube bending process, and manual assembly process. This OEM offers its dealer–customers a wide variety of sub systems to an extent that no two vehicles in the production line are similar.

This firm has a custom-built engineering change management system to manage all engineering changes. This system is common to other divisions of the OEM located in different geographical locations within and outside the United States. Users from any department in any location (e.g., manufacturing engineers, quality engineers, production planners, purchasing professionals, and senior management) may access the Internet-based engineering change management system to archive and retrieve information from the system. For instance, production planners may search for the introduction date of a product to initiate necessary actions at their end to ensure smooth production while managers may search for information related to the time elapsed between the beginning and end of an EC.

The communication of an EC between departments in the manufacturing firm is through different online forms such as engineering change note (ECN), engineering release note (ERN), substitutions, and deviations. The sole authority to issue these forms are within the engineering department. ERN is used to communicate the release of a new product, whereas an ECN is used to communicate any modification in the product. However, an alternate approach is used to address the concerns/issues identified during production, whereas the formal ECN document is bypassed to minimize the product delivery lead time. This approach is known as a containment action with its associated forms known as deviation and substitution. Deviations are short-term departures from compliance with engineering drawing specifications for a specific number of parts after manufacture. Substitutions are a subset of deviation in which a part ‘x’ is replaced with a part ‘y’, before manufacturing, based on written authorization. These deviations are later formalized with an ECN, however, and in this firm, the emergent changes are handled using deviations/substitutions.

All employees, as identified by the management, attend two-week training sessions to learn this software that supports the engineering change process and are examined and graded at the end of these sessions. Upon achieving satisfactory performance, the employee is then provided a password so that they may engage in daily system operation activities. The degree of accessibility to specific components in the software such as approval of deviation is defined by the system administrator based upon department, job description, and degree of responsibility held by the executive.

The online system allows any authorized user from manufacturing, production planning, inventory, and design department to request a substitution or deviation in two separate forms. Each of these forms contains the following data to be entered by the user in the system: (1) the reason for substitutions or deviations, (2) a short description of the problem, (3) the associated part numbers, (4) the number of parts for which the deviation/substitution is requested, (5) and duration of the deviation/substitution. The name and department of the requestor, approver, and manager are also required. Files (e.g., Microsoft (MS) power point files, MS excel files, and MS word files) may also be attached describing the emergent changes, the handling of which is described in the next section.

3.2 The EC process

A flow chart, presented in Fig. 2, is used to describe this change process, which begins with the identification of a concern. Identified by any department in the manufacturing firm, problems are reported to the engineering department through the online system described above using the deviation/substitution request form. Depending on the situation, concerns are classified as either a substitution or a deviation. The engineer from the product support group discusses the issue with other associates in the department concerned, and the engineer develops a feasible interim solution to ensure uninterrupted production. This solution is then reviewed and approved by the product support manager, which is then communicated to the manufacturing and quality department. The time elapsed between concern initiation and approval of deviation varies between 1 and 3 days.

Subsequently, if the approved deviation/substitution requires design document changes, an appropriate work authorization is issued with which an engineering release number is obtained from the system. A permanent engineering solution is then developed either by the product support engineer or in collaboration with the product development engineers within the engineering department. The necessary design documents such as drawings, bills of material (BOM) are updated in the information management system such as the product data management (PDM) and reviewed by focus groups before being made available to manufacturing. At the end of this process, the concern is closed by the product support engineer. The time elapsed between the work authorization and closing the concern vary between 30 and 60 days.

The use of deviation/substitutions approach to manage the ECs is a simplified approval and documentation method of an EC, which does not require design document updates. Because ECs identified during the production must be resolved quickly, necessary documents are also created quickly for quality purposes to ensure timely vehicle delivery. However, at a later stage, the design documents are updated through a formal ECN by raising a work authorization. Therefore, because of the likelihood that propagation causes substitution and deviation in the production process, data related to these changes (including substitutions and deviations) are retrieved from the archival record, which is explained in the next section.

3.3 Data collection from the archival records

Over 1200 EC’s archival records from the OEM’s online ECM system between September 2006 and June 2009 were analyzed to identify the reasons for the emergent changes. The collected 1200 ECs were significant for establishing a trend and identifying the reasons behind a greater percentage of occurrences. These reasons are classified into internal and external changes based upon who initiated the change (Jarratt et al. 2006; Ahmed and Kanike 2007). For instance, a change initiated by the manufacturing department is an internal change while the one initiated by the supplier is an external change. In addition, classification is also performed based upon the nature of the change (Ahmed and Kanike 2007) such as time of change, motivation of change, result of change, type of problem, drawing and design error rectification, and manufacturing and assembly problems.

4 Reasons for engineering changes

A large set of EC records (1,241), analyzed to determine the rational for the change, were classified based upon the nature and initiation of the change. The author determined that 77.0 % of the reports were initiated internally with the remaining 23.0 % initiated externally as shown in Fig. 3. Within the 77.0 % of internal changes, 28.9 % were document error corrections such as BOM error (9.7 %), drawing error (16.6 %), and introduction date error in ECN (2.0 %). Cost reduction exercises accounted for 15.7 %, the second highest, closely followed by manufacturing issues which accounted for 14.3 %. Design corrections such as addressing field problems, parts that did not fit into the vehicle, and other design limitations accounted for 9.1 % of errors, while inventory issues such as material shortages necessary to produce the vehicles and obsolete materials accounted for 9.0 %. However, management attempted to use these materials in any future vehicles when feasible. Finally, regarding external changes, 21.3 % were due to cost reduction exercises initiated by the vendor while changes due to requirement change accounts for a scant 0.7 %. Such changes though small cannot be dismissed, as other researchers have studied change propagation based upon such requirement changes (Morkos and Summers 2010).

From Fig. 3, it can be inferred that this OEM spends significant effort in correcting drawing errors. To avoid overlaps between design and drawing errors, each of these drawings was reviewed individually. It was determined that such errors are typically due to the reuse of drawings such as modifying older versions to update missing sections and CAD software errors such as incorrect placement of dimensions. It was also determined that this OEM should develop a quality assurance method in the release of BOM which, from the researcher’s perspective, is extremely complex to understand and use due to its structure rather than content.

It is also observed during the internship that the release of BOM with errors such as incorrect part quantity, missing required assembly part numbers leads to disruption in production such as shortage of materials to build the vehicle. This effect, in turn, must be addressed by the design department by providing an equivalent alternate part, if technically feasible, to ensure continuous productivity. Though this EC’s cause–effect–cause–effect pattern is analogous to the definition of change propagation, it is due to the interlinked functional groups within an organization and not due to either the direct or indirect links within a product. Thus, to understand the reasons of propagation across the functional domain within an organization, it is essential to further classify these ECs into genesis and propagated changes and subsequently identify the reasons for propagated changes. As archived reports do not show these causal relationships explicitly, a matrix-based approach is used to capture these cause–effect patterns of various reasons for changes at a detailed level based on the engineers’ experience. Interviews with engineers, the protocol of analysis, and interpretation of these interviews are presented below.

5 Data collection and analysis from the focused interview

The product support engineers in the engineering department are those who directly deal with sustaining the production line. Therefore, all six product support engineers, located at the investigation site, as well as the product support manager were interviewed. The qualifications of the engineers, their years of experience at the investigation site and at different auto companies, and their job titles are presented in Table 1.

The interviewee was informed about the theme of the interview a week in advance to provide them with ample opportunity to formulate their responses and provide examples of production changes from their own experience. It was the first time that several of the interviewees had explicitly considered the events that led to a change, the implication being that no explicit answers were forthcoming. Thus, follow-up questions were posed to interviewees to collect this relevant information.

Additionally, the interaction between ECs—known as the change interaction model (CIM) for simplicity—was modeled using the domain mapping matrix (DMM) (Danilovic and Browning 2007) based upon the reasons for ECs with the investigator’s prior work experience and previous literature (Ahmed and Kanike 2007; Jarratt et al. 2005, 2006; Watts 1984b; Huang et al. 2003; Huang and Mak 1997; Fricke et al. 2000). This matrix is used as a guiding instrument to enable interviewees to remind them of previously similar occurrences should they be at a loss for such examples. The sources and the reasons used in CIM are presented in Table 2. It should be noted that manufacturing and assembly are regarded as two individual sources because an OEM can internally manufacture parts such as front axle for a heavy commercial vehicle for subsequent assembly with parts bought from various suppliers. The process of developing a CIM is presented in Sect. 5.1.

5.1 Process of constructing a CIM

The entries presented in Table 2 are represented as rows and columns of the DMM. The scenarios from the prior experience are reconstructed and modeled in the CIM as causal relation. These relationships are identified in the matrix with a binary numbering scheme in which ‘1’ indicates a relationship and ‘0’ indicates none. The zeros are not shown in the snapshot to improve the readability of the matrix. A snapshot of the CIM used prior to any interview is presented in Fig. 4.

5.2 Interview questions

The interviews were audio-recorded and conducted in a closed conference room with all questions following a triangulation scheme, as shown in Table 3, to establish validity of the results. The questionnaire used in the interview process is presented in Fig. 5. The second question explores the reasons for the changes from the engineering design department while the seventh question explores the same from a different perspective.

At the end of the interview, the interviewees were requested to verify the CIM and suggest any changes. All interviews were then transcribed and presented to the interviewee for their review regarding accuracy. Upon confirmation, this document was used to update the CIM with the newly identified reasons for changes and used in subsequent interviews.

5.3 Interview analysis protocol

The examples provided by each interviewee were processed by the authors using a set protocol. Objective was to determine the reason leading to an EC, each example was studied in detail for its context (if provided by the interviewee), the event leading to an EC, and the cause and effect. Interview results are illustrated in Table 4.

The examples provided by each interviewee are processed by a set protocol. The objective is to determine the primary cause that led to a change; therefore, each example is studied in detail for its context (if provided by the interviewee), the event that led to the change, the cause, and the effect.

After elucidating the context of each example elicited by the interviewee, the event leading to an EC was recorded in the second column. The end result (effect) of the situation was then identified such as a ‘wrong assembly’, ‘material shortage’, and ‘process change’. The cause of this end result is determined by a why–why analysis until a point at which cause represents the situation determined under study. For instance, the ‘operator error’ cause was not further decomposed into why the operator made the error as it digressed from the context boundary. Also, the changes caused by supplier’s error were not examined in detail as they fall outside of the scope of this research.

5.4 Identifying genesis and propagated change from CIM

After interviewing all interviewees, a consolidated CIM (as shown in Fig. 7) was developed which captures the causal relationship of ECs from the examples elicited by all interviewees. A genesis change is identified if entries in the column lacked any relationship with the entries in the corresponding row of that column while propagated changes are those which did not follow this rule. Additionally, entries without any relationships were deleted from this inquiry. Such non-relationship entries are illustrated with a representative CIM in Fig. 6, where A, B, C, D, and E represent different reasons for ECs. The causal relationships are identified based upon the protocol described in Sect. 5.3

It is inferred from Fig. 6 that EC caused by reason ‘A’ is a genesis change because it led to other ECs such as ‘B’ and ‘D’. The reasons ‘B’ and ‘D’ are propagated changes caused by a previous change, which in turn caused a subsequent change. There is one more category of propagated change, which was caused by other reasons causing no subsequent changes such as ‘E’. The final category has entries that are neither caused by nor causes an EC; such entries are deleted from the consolidated CIM. Upon identification of propagated changes, the reasons for propagation can be directly read from the rows related to the corresponding column. For instance, D is due to both A and B.

6 Reasons for propagated changes

In this section, the author explains the differences between genesis and propagated changes for changes identified in Section 4 and the reasons for these propagated changes. Cost reduction, both internal and external, and customer requirement change are identified as genesis changes from the consolidated CIM. Also, the document error rectification change acts as genesis change. For instance, a ‘bill of material error’ is due to (1) incorrect mention of part quantity; (2) incorrect mention of part numbers; and (3) incorrect mention of part life. These errors result in material shortage which is illustrated by an example elicited by Interviewee #3.

The biggest cause of part shortages is the incorrect BOM. For example, we have small rubber caps that we place inside of the bulk heads to cover up the screw heads. The BOM called up 17 numbers whereas in reality each vehicle took up 60.

All other interviewees expressed similar views on this reason, constituting 9.7 % of the total changes. As explained in Sect. 4, the effect of BOM error will again cause the design department to substitute with alternate parts, if it is feasible, to sustain the production line.

Inventory issues such as shortage of materials and holdings of obsolete parts are identified as propagated changes. As a propagated change, the reason for shortage of materials is due to incorrect BOM. Specifically, ECs on the BOM with incorrect part quantity cause production planner to plan only for the quantity described in the BOM, resulting in a line stop when material inventories are exhausted. To avoid this scenario, there must be manufacturing request to design to replace the existing part with a similarly equivalent part, thus, leading to subsequent change. Another inventory issue involves the obsolete material that ended up in inventory as a result of higher part quantities in BOM than required. Such excess inventory is also due to the release of ECs without considering the existing inventory in the plant. Interviewee #2 described this scenario.

Marketing proposed a cost reduction suggestion with a decal. The engineering change propagated for all models while there were 200 numbers of old badge in the inventory. This led to a change.

Design error rectification is identified as propagated change emanating from the consolidated CIM. The term ‘design error’ encompasses design limitations such as poor design assumptions, incorrect installation layout, out-of-date CAD drawings and 3D models, a lack of understanding of the system by the designers, and failing to meet customer requirements. Interviewee #4 described such a scenario in which EC was released to address design limitations. He stated that:

Several fuel tanks failed in the field and there was an immediate instruction to replace them. This led to a change.

Finally, manufacturing issues are also identified as propagated changes from the consolidated CIM because the methods for improving the product changed the existing production processes on the shop floor. Interviewee #4 again:

We changed out to disk brakes. That was a process change for material handling because the components were heavier.

Here, hydraulic brakes were changed to disk brakes to improve the final product. This product change, however, interfered with the material handling process, mandating a change. Because the forklifts for carrying a set number of hydraulic brakes were not rated to carry an equivalent number of disk brakes, the process was redesigned to allow production to continue using altered loading criteria.

In another instance, an organizational initiative to consolidate vendors to reduce costs led to part consolidation, also interfered with production processes, as described by Interviewee #2.

Lights were purchased with multiple vendors and to consolidate the price purchasing department consolidates the vendors which lead to number of changes.

Similarly, raw materials were changed to reduce tool wear rate, and design specifications were changed to accommodate the shortcomings of inadequate maintenance of the machine. Other causes for reworking existing processes involved design errors and drawing errors such as incorrect installation layout.

Table 5 presents the identified propagated changes from the list of archival records, which account for 32.4 % of the total in this OEM, of which manufacturing issues accounted for 14.3 %. By considering recommended manufacturing changes from designers and communicating this change and its implications to production prior to implementation, such changes can be reduced.

Inventory issues accounted for 9.0 %, which was due to the incorrect release of engineering documents such as BOM. Also, introduction dates were included by the designers in the ECN without communicating with the purchasing department, thus increasing the difficulty of making an efficient change in production. To avoid such communication errors, the decision-making responsibility for such production changes must be left to the purchasing department on the date of the change. Since the ECM is electronically controlled, it is possible to distribute the ownership of the document between the designer and the associate in the purchasing department, which will eliminate such errors. Logistics issues between the end-user OEM and its suppliers also contribute to inventory volatility. To ensure a steady supply of materials, redundancies must be developed to accommodate delays in shipment from natural disasters, supplier strikes, and incomplete shipment inventories.

Rectifying design errors account for 9.1 % of all propagated changes due to the release and reuse of out-of-date 3D models and drawings by the designer, incorrect installation layout, and limited understanding of the complex system. Though the designers use Failure Mode and Effect Analysis (FMEA) and design review to mitigate such changes, these tools are inherently limited in their ability to effectively support incremental product design. Such limitations must be identified to support product changes in complex systems during the production phase and thus reduce design errors.

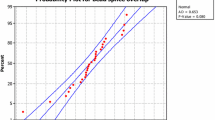

7 Validity of this research

Research results regarding the presence of ECs in the production phase are generalized by comparing the results with those of similar research. The ratio of internal-to-external changes, 77:23, identified from the archival records directly aligns with the previous case study conducted in an aero-engine product (Ahmed and Kanike 2007) and in a large sized compressor-and-pumps manufacturing company (Harhalakis 1986). Based upon these results, it can be generalized that the ratio of internal-to-external changes exhibits a similar trend between different mechanical systems with varying degrees of complexity. The reasons for the presence were also similar, but with varying proportions.

Reasons for propagation are identified from multiple sources of evidence using data triangulation approach, which for the purposes of this research did not mimic the replication logic as in the survey-based research technique used in statistical sampling (Stowe 2008; Teegavarapu et al. 2008; Teegavarapu 2009). Although the results are from single critical case, single case study proponents suggest presenting the findings as ‘user generalizable’ by providing a detailed explanation of the context under which the study is conducted, thereby providing users with the opportunity to reach their own conclusions regarding the applicability of these results to specific situations (Kennedy 1979).

8 Conclusion

The objective of this research was to understand the reasons for change propagation during the production phase of the product life cycle using case study research methodology in an automotive OEM. It is inferred from the analysis of 1241 archival reports that 77.0 % of changes are due to internal reasons while 23.0 % are external. This trend directly aligns with a 2007 study of an aircraft engine manufacturer and a study of a large compressor and pumps manufacturer. Although the products exhibit varying degrees of complexity, the reasons for changes and their proportion (internal-to-external changes) were in remarkably good agreement. Such consistency implies that strategies used to contain propagation changes can be horizontally deployed from highly developed to less complex systems.

The reasons for changes and their proportion from three different case studies, including this one, indicate no significant improvement in the containment of ECs over the past quarter century, despite the increased EC research. Industries are still experiencing high volume of changes, which directly affect product cost and lead time. Thus, both the manufacturing and research community must increase their efforts to effectively develop tools and management strategies to contain these unplanned (propagated) changes. In this research, the author, working in the Clemson Engineering Design and Application Research (CEDAR) laboratory, used a matrix-based modeling approach to identify the reasons for propagation occurrence. A review of existing manufacturing design processes indicates that 32.4 % of the total changes are propagated changes, which were primarily due to document and design error occurring during the engineering release. Industries can perhaps reduce EC time by one-third and the associated costs by creating sophisticated appropriate controls to provide redundancy in document release to avoid propagated changes in both supply inventories and manufacturing processes. In order to reduce propagation due to design limitations such as field failure, suitable controls must be developed through the improvement of existing tools and in the development of new designs. In future, it is planned to develop a systematic verification and validation plan as a control to reduce propagation effects. However, limitations in the existing design tool with respect to change propagation will be determined, and this limitation will be addressed in the systematic verification and validation plan that is planned to be developed. In addition, further case studies have to be conducted in different industries, such as electronics and computers, to determine the reasons for propagated changes to develop a generalization.

This study confirms that changes can propagate across the functional domain in a manufacturing firm, causing unplanned changes, which is in contrary to the canonical concept of change propagation currently restricting the study of propagation within the product. Thus, it is essential to consider this aspect in future change propagation research, which will enable the creation of new management tools to support changes in incremental product design.

References

Ahmed S, Kanike Y (2007) Engineering change during a product’s lifecycle. Paper presented at the international conference on engineering design, Paris, France, August 28–31

Ameri F, Summers JD, Mocko GM, Porter M (2008) Engineering design complexity: an investigation of methods and measures. Res Eng Des 19(2–3):161–179

Boznak RG, Decker AK (1993) Competitive product development: a quality approach to succeeding in the 1990s and beyond. Business One Irwin/Qualiy Press, Milwaukee

Clark KB, Fujimoto T (1991) Product development performance: strategy, organisation and management in the world auto industry. Harvard Business School Press, Cambridge, MA

Clarkson PJ, Simons C, Eckert C (2004) Predicting change propagation in complex design. J Mech Des 126(5):788–797

Danilovic M, Browning T (2007) Managing complex product development projects with design structure matrices and domain mapping matrices. Int J Project Manage 25(3):300–314

Duhovnik J, Tavcar J (2002) Reengineering with rapid prototyping. Paper presented at the tools and methods of competitive engineering (TMCE), Wuhan, China, April 22–26

Eckert C, Zanker W, Clarkson JP (2001) Aspects of a better understanding of changes. Paper presented at the international conference on engineering design, ICED’01, Glasgow, UK, August 21–23

Eckert CM, Pulm U, Jarratt TA (2003) Mass customisation, change and inspiration: changing designs to meet new needs. Paper presented at the international conference on engineering design’03, Stockholm, 19–21 August

Eckert C, Clarkson J, Zanker W (2004) Change and customisation in complex engineering domains. Res Eng Des 15(1):1–21

Flyvbjerg B (2004) Five misunderstanding about case study research. Qual Inq 12(2):219–245

Fricke E, Gebhard B, Negele H, Igenbergs E (2000) Coping with changes: causes, findings, and strategies. Syst Eng 3(4):169–179

Frost R (1999) Why does industry ignore design science? J Eng Des 10(4):301–304

George A, Bennett A (2005) Case studies and theory development in the social sciences. MIT Press, Cambridge

Giffin ML (2007) Change propagation in large technical systems. Massachusetts Institute of Technology, Massachusetts

Harhalakis G (1986) Engineering changes for made to order products: how an MRP system should handle them. Eng Manag Int 4:19–36

Huang GQ, Johnstone G (1995) CMCEA: Change mode, cause and effects analysis: a concurrent engineering approach to cost-effective management of product design changes. Paper presented at the international conference on engineering design’95, Praha, Czech Republic, August 22–24

Huang GQ, Mak LK (1997) Engineering change management: a survey within UK manufacturing industries. Paper presented at the first international conference: managing enterprises-stakeholders, engineering, logistics, and achievement (ME-SELA), Loughborough University. Loughbourough, July 22–24

Huang GQ, Mak LK (1999) Current practices of engineering change management in UK manufacturing industries. Int J Oper Prod Manag 19(1):21–37

Huang GQ, Yee WY, Mak KL (2001) Development of a web based system for engineering change management. Robot Comput Integr Manuf 17(3):255–267

Huang GQ, Yee WY, Mak KL (2003) Current practice of engineering change management in Hong Kong manufacturing industries. J Mater Process Technol 139(1–3):481–487

Innes JG (1994) Achieving successful product change: a handbook (Financial Times/Pitman publishing management series). Trans-Atlantic publications, Pennsylvania

Jarratt T, Clarkson J, Eckert C (2005) Engineering change. In: Design process improvement: a review of current practice. Springer, London Limited, London

Jarratt T, Eckert C, Clarkson JP (2006) Pitfalls of engineering change: change practice during complex product design. In: Advances in design, 1st edn. Springer series in Advanced Manufacturing, Germany, pp 413–424

Kennedy MM (1979) Generalizing from single case studies. Eval Q 3(4):661–678

Kidd MW, Thompson G (2000) Engineering design change management. Integr Manuf Syst 11(1):74–77

Loch CH, Terwiesch C (1999) Accelerating the process of engineering change orders: capacity and congestion effects. J Prod Innov Manage 16(2):145–159

Matheison JL, Summers JD (2010) Complexity metrics for directional node link system representations: Theory and applications. In: Proceedings of the ASME 2010 international design engineering technical conferences and computers and information in engineering conference, Quebec, Canada, 2010. ASME

Maull R, Hughes D, Bennett J (1992) The role of the bill-of materials as a CAD/CAPM interface and the key importance of engineering change control. Comput Control Eng J 3(2):63–70

Morkos B, Summers JD (2010) Requirement change propagation prediction approach: results from an industry case study. In: Proceedings of the ASME 2010 international design engineering technical conferences and computers and information in engineering conference, Quebec, Canada, August 15–18

Ollinger GA, Stahovich TF (2001) Redesign IT: a constraint based tool for managing design changes. Paper presented at the design engineering technical conferences and computers and information in engineering design, Pittsburgh, Pennsylvania, USA, September 9–12

Pahl G, Beitz W, Feldhusen J, Grote KH (2007) Engineering design: a systematic approach, 3rd edn. Springer, London Limited, London

Pikosz P, Malmqvist J (1998) A comparative study of engineering change management in three Swedish engineering companies. In: Proceedings of the ASME design engineering technical conferences, Atlanta, GA, USA

Roth S (1999) The state of design research, design issues. Design Res 15(2):18–26

Rouibah K, Kevin CR (2003) Change management in concurrent engineering from parameter perspective. Comput Ind 50(1):15–34

Sheldon D (2006) Design review 2005/2006: the ever increasing maturity of design research papers and case studies. J Eng Des 17(6):481–486

Soderberg LG (1989) Facing up to the engineering gap. McKinsey Quarterly Spring 3

Stowe D (2008) Investigating the role of prototyping in mechanical design using case study validation. Clemson University, Clemson

Summers JD, Shah JJ (2003) Developing measures of complexity for engineering design. Paper presented at the international conference on design theory and methodology, Chicago, IL, USA, September 2–6

Teegavarapu S (2009) Foundation of design method development. Dissertation, Clemson University

Teegavarapu S, Summers JD, Mocko G (2008) Case study method for design research: justification. Paper presented at the ASME–DETC 2008, New York

Terwiesch C, Loch CH (1999) Managing the process of engineering change orders: the case of the climate control system in automobile development. J Product Innov 16(2):160–172

Vianello G, Ahmed S (2008) Engineering changes during the service phase. In: Proceedings of the ASME 2008 international design engineering technical conferences and computers and information in engineering conference, New York, USA, August 3–6

Watts F (1984a) Engineering changes: a case study. J Product Invent Manag 25(4):55–62

Watts F (1984b) Engineering changes: a case study. Product Invent Manag 2(4):55–62

Williams OJ (1983) Change control in the job shop environment. In: Proceedings of the 26th annual international conference of the American production and inventory control society, Toronto, Canada, pp 496–498

Wright IC (1997) A review of research into engineering change management: implications for product design. Des Stud 18(1):33–42

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shankar, P., Morkos, B. & Summers, J.D. Reasons for change propagation: a case study in an automotive OEM. Res Eng Design 23, 291–303 (2012). https://doi.org/10.1007/s00163-012-0132-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00163-012-0132-2