Abstract

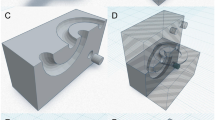

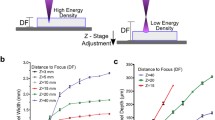

In this work we characterize a novel possibility for PDMS (PolyDiMethylSiloxane) casting/ micromolding methods with the utilization of molding forms fabricated by a commercially available novel acrylic photopolymer based 3D printing method. The quality and absolute spatial accuracy of 1) different 3D printing modes (‘matt’ vs. ‘glossy’); 2) the molded PDMS structures and 3) the subsequently produced complementary structures made of epoxy resin were investigated. The outcome of these two form transfer technologies were evaluated by the cross sectional analysis of open microfluidic channels (trenches) with various design. Our results reveal the spatial accuracy in terms of real vs. CAD (Computer Aided Design) values for the 3D printed acrylic structures and the limits of their form transfer to PDMS, then to epoxy structures. Additionally the significant differences between the various spatial directions (X, Y, Z) have been characterized, and the conclusion was drawn that the ‘glossy’ printing mode is not appropriate for 3D printing of microfluidic molds.

Similar content being viewed by others

References

Lee D, Sukumar P, Mahyuddin A, Choolani M, Xua G (2010) Separation of model mixtures of epsilon-globin positive fetal nucleated red blood cells and anucleate erythrocytes using a microfluidic device. J Chromatogr A 1217:1862–1866

Hu M, Deng R, Schumacher KM, Kurisawa M, Ye H, Purnamawati K, Ying JY (2010) Hydrodynamic spinning of hydrogel fibers. Biomaterials 31:863–869

Piliarik M, Vala M, Tichy I, Homola J (2009) Compact and low-cost biosensor based on novel approach to spectroscopy of surface plasmons. Biosens Bioelectron 24:3430–3435

Faber J, Berto PM, Quaresma M (2006) Rapid prototyping as a tool for diagnosis and treatment planning for maxillary canine impaction. Am J Orthod Dentofacial Orthop 129(4):583–589

Ciuffolo F, Epifania E, Duranti G, De Luca V, Raviglia D, Rezza S, Festa F (2006) Rapid prototyping: a new method of preparing trays for indirect bonding. Am J Orthod Dentofacial Orthop 129(4):75–77

Cohen A, Laviv A, Berman P, Nashef R, Abu-Tair J (2009) Mandibular reconstruction using stereolithographic 3-dimensional printing modeling technology. Oral Surg Oral Med Oral Pathol Oral Radiol Endod 108(5):661–666

Kim MS, Hansgen AR, Carroll JD (2008) Use of rapid prototyping in the care of patients with structural heart disease. Trends Cardiovasc Med 18(6):210–216

Haraldsson KT, Hutchison JB, Sebra RP, Good BT, Anseth KS, Bowman CN (2006) 3D polymeric microfluidic device fabrication via contact liquid photolithographic polymerization (CLiPP). Sensor Actuator B 113:454–460

Thomas MS, Millare B, Clift JM, Bao D, Hong C, Vullev VI (2009) Print-and-peel fabrication for microfluidics: what’s in it for biomedical applications? Ann Biomed Eng 38(1):21–32

Do J, Zhang JY, Klapperich CM (2011) Maskless writing of microfluidics: Rapid prototyping of 3D microfluidics using scratch on a polymer substrate. Robot Comput Integr Manuf 27(2):245–248

Cooper McDonald J, Chabinyc ML, Metallo SJ, Anderson JR, Stroock AD, Whitesides GM (2002) Prototyping of microfluidic devices in poly(dimethylsiloxane) using solid-object printing. Anal Chem 74:1537–1545

Bonyár A, Sántha H, Ring B, Varga M, Kovács JG, Harsányi G (2010) 3D Rapid prototyping technology (RPT) as a powerful tool in microfluidic development. Procedia Engineering 5:291–294

Plecis A, Chen Y (2008) Improved glass–PDMS–glass device technology for accurate measurements of electro-osmotic mobilities. Microelectron Eng 85:1334–1336

Haubert K, Drier T, Beebe D (2006) PDMS bonding by means of a portable, low-cost corona system. Lab Chip 6:1548–1549

Kim J, Surapaneni R, Gale BK (2009) Rapid prototyping of microfluidic systems using a PDMS/polymer tape composite. Lab Chip 9:1290–1293

Shih T-K, Chen C-F, Ho J-R, Chuang F-T (2006) Fabrication of PDMS (polydimethylsiloxane) microlens and diffuser using replica molding. Microelectron Eng 83:2499–2503

Berdichevsky Y, Khandurina J, Guttman A, Lo Y-H (2004) UV/ozone modification of poly(dimethylsiloxane) microfluidic channels. Sensor Actuator B 97:402–408

Acknowledgments

The authors would like to thank for the financial support of the following EC funded FP6 projects: DVT-IMP (FP6-2005-IST-5- 034256), DINAMICS (IP 026804-2), RASP (SP5A-CT-2006-044515); Hungarian Jedlik Ányos Programme: SPE_SAFE (Contract nr. NKFP_07-A2-2008-0268). This work is connected to the scientific program of the " Development of quality-oriented and harmonized R + D + I strategy and functional model at BME" project. This project is supported by the New Hungary Development Plan (Project ID: TÁMOP-4.2.1/B-09/1/KMR-2010-0002).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bonyár, A., Sántha, H., Varga, M. et al. Characterization of rapid PDMS casting technique utilizing molding forms fabricated by 3D rapid prototyping technology (RPT). Int J Mater Form 7, 189–196 (2014). https://doi.org/10.1007/s12289-012-1119-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12289-012-1119-2