Abstract

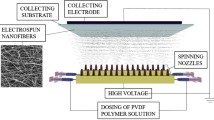

Electrospinning is a fabrication process that uses an electric field to make polymer nanofibers. Nanofibers have a large specific surface area and a small pore size; these are good properties for filtration applications. In this paper, the filtration characteristics of a Nylon 6 nanofilter made by electrospun nanofibers are tested as a function of the fiber diameter. Nanofilter media with diameters in the range of 100–730 nm can be produced in optimized conditions. The pressure drop of a Nylon 6 nanofilter linearly increases with the increasing face velocity. An electrospun Nylon 6 filter (mean fiber diameter: 100 nm) shows a much lower pressure drop performance relative to the commercial HEPA filter media when the filtration efficiency of the Nylon 6 nanofilter and the HEPA filter are over 99.98% with test particles of 0.02–1.0 μm in diameter. The pressure drop at 5 cm/s of the face velocity is measured as 27 mmAq for the Nylon 6 nanofilter media, and 37.1 mmAq for the HEPA filter media. The particle size with minimum efficiency decreases with the decreasing fiber diameter. And the minimum efficiency becomes greater as the fiber diameter is decreased.

Similar content being viewed by others

References

S. M. Jo, W. S. Lee and S.W. Chun, Fiber Technology and Industry, 6(1/2), 61 (2002).

K. Graham, M. Ouyang, T. Raether, B. McDonald and P. Knauf, Polymeric nanofilters in air filtration applications, 15th Annual Technical Conference, Texas, April 9 (2002).

D. H. Reneker and I. Chun, Nanotechnology, 7, 216 (1996).

K.W. Lee and B. Y. H. Liu, J. Air Poll. Control Assoc., 30, 377 (1980).

D. H. Reneker, A. L. Yarin, H. Fong and S. Koombhongse, Journal of Applied Physics, 87, 9, 4531 (2000).

J. M. Deitzwl, J. D. Kleinmeyer, D. Harris and N. C. Becktan, Polymer, 42, 261 (2001).

Y. C. Ahn, S. K. Park, G. T. Kim, Y. J. Hwang, C.G. Lee, H. S. Shin and J. K. Lee, Current Applied Physics, 6, 1030 (2006).

ASHRAE Standard 52.1, Method of Testing General Ventilation Air-Cleaning Devices for Removal Efficiency by Particle Size (1999).

W. C. Hinds, Aerosol technology, John Wiley & Sons, New York (1999).

G. T. Kim, Y. C. Ahn, J. K. Lee, N. Kattamuri and C. M. Sung, J. Ilass-Korea, 8, 31 (2003).

G. T. Kim, Y. J. Hwang, Y. C. Ahn, H. S. Shin, J. K. Lee and C. M. Sung, Korean J. Chem. Eng., 22, 147 (2005).

H. S. Park and Y. O. Park, Korean J. Chem. Eng., 22, 165 (2005).

R. C. Brown, Air filtration: An integrated approach to the theory and applications of fibrous filters, Pergamon Press (1993).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kim, G.T., Ahn, Y.C. & Lee, J.K. Characteristics of Nylon 6 nanofilter for removing ultra fine particles. Korean J. Chem. Eng. 25, 368–372 (2008). https://doi.org/10.1007/s11814-008-0061-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11814-008-0061-y