Absrtact

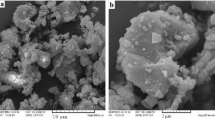

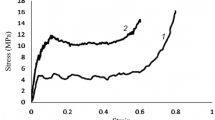

Aluminum foams are commonly produced using hydride foaming agents. Carbonates are inexpensive and more convenient to handle than hydrides. In this review article, the replacement of titanium hydride by carbonate foaming agents in aluminum and aluminum alloys was studied. Carbonate-foaming agents including calcium carbonate, magnesium carbonate, and dolomite were investigated for the production of aluminum and aluminum alloys. The thermal decomposition behavior of the foaming agents was evaluated in conjunction with the cell structure of the aluminum foams produced. From the results, magnesium carbonate and dolomite were selected as suitable foaming agents for aluminum alloys because of lower decomposition temperature than calcium carbonate. It was clarified that dolomite resulted in a fine and homogenous cell structures.

Similar content being viewed by others

References

[1] V.C. Srivastava and K.L. Sahoo: Mater. Sci. Poland, 2007, vol. 25, pp. 733-53.

[2] I. Paulin, B. Sustarsic, V. Kevorkijan, S.D. Skapin, and M. Jenko: Mater. Tech., 2011, vol. 45, pp. 13-9.

[3] V. Kevorkijan, S. D. Skapin, I. Paulin, B. Sustarsic, and M. Jenko: Mater. Tech., 2010, vol. 44, pp. 363-71.

[4] V. Gergely, D.C. Curra, and T.W. Clyne: Compos. Sci. Tech., 2003, vol. 63, pp. 2301-10.

[5] T. Koizumi, K. Kido, K. Kita, and K. Mikado: Mater. Trans., 2011, vol. 52, pp. 728-33.

[6] D.P. Papadopoulos, H. Omar, F. Stergioudi, S.A. Tsipas, and N. Michailidis: Colloids Surf. A. Physicochem. Eng. Aspects, 2011, vol. 382, pp. 118-23.

[7] V. Kevokijan: MJoM, 2010, vol. 16, pp. 205-19.

[8] M. Haesche, D. Lehmus, J. Weise, M. Wichmann, I. Cristina, and M. Mocelline: J. Mater. Sci. Tech., 2010, 26, pp. 845-50.

L.E.G. Cambronero, J.M. Ruiz Roman, F.A. Corpas, and J.M. Ruiz Prieto: J. Mater. Proc. Technol., 2009, vol. 209, pp. 1803–09.

F.L. Cuthbert and R.A. Rowland: Am. Mineral., 1947, vol. 32, pp. 111–16.

[11] A.V. Byakova, S.V. Gnyloskurenko, A.I. Sirko, Y.V. Milman, and T. Nakamura: Mater. Trans., 2006, vol. 47, pp. 2131-6.

C. Umashankar, K. Jha, and K.N. Mahule: BARC Newsl., 2011, vol. 322, pp. 39–43.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted February 23, 2014.

Rights and permissions

About this article

Cite this article

Soloki, A., Esmailian, M. Carbonate-Foaming Agents in Aluminum Foams: Advantages and Perspectives. Metall Mater Trans B 46, 1052–1057 (2015). https://doi.org/10.1007/s11663-014-0262-1

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-014-0262-1