Abstract

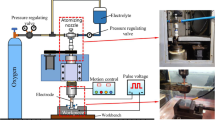

Fine metal particles are produced by chemical methods, which add surfactants to control particle size and concentration. This study used the submerged arc discharge method (SADM) to prepare metal fluid containing nanoparticles and submicron particles in pure dielectric fluid (deionized water or alcohol). The process is fast and simple, and it does not require the addition of chemical agents. The SADM uses electrical discharge machining (EDM) equipment, and the key parameters of the production process include discharge voltage, current, and pulse discharge on-off duration. This study added a capacitive component between the electrodes and the electrode Z-axis regulation in the control parameters to render the aluminum fluid process smooth, which is the main difference of this article from the literature. The experimental results showed that SADM can produce aluminum particles from nanometer to submicron grade, and it can obtain different compounds from different dielectric fluids. The dielectric fluids used in this study were deionized water and ethanol, and aluminum hydroxide Al(OH)3 particles with suspending power and precipitated aluminum particles were obtained, respectively. The preparations of metal colloid and particles by the SADM process have the characteristics of low cost, high efficiency, high speed, and mass production. Thus, the process has high research value and developmental opportunities.

Similar content being viewed by others

References

M.H. Chowdhury, K. Ray, S.K. Gray, J. Pond, and J.R. Lakowicz: Anal. Chem., 2009, vol. 81, pp. 1397–1403.

P. Nayak, S.K. Das, and D.M. Vasudevan: Indian J. Clin. Biochem., 2006, vol. 21, pp. 53–57.

F. Wu and W. Hu: Adv. Mater. Res., 2012, vols. 415–417, pp. 545–48.

H. Hasan: Aluminum, Rosen Pub Group, New York, NY, 2007, p. 34.

A. Alrashdan, A.T. Mayyas, A.M. Hassan, and M.T. Hayajneh: J. Compos. Mater., 2011, vol. 45, pp. 2091–2101.

Y.Z. Yue, Y. Hao, Q. Feng, J. Zhang, X. Ma, and J. Ni: Sci. China Ser. E : Technol. Sci., 2009, vol. 52, pp. 2762–66.

S. Nayak and N. Dahotre: JOM, 2002, vol. 54, pp. 39–41.

J.J. Hao, C.R. Wang, X.Y. Liu, X.Q. Pu, C.Y. Dong, Y.Y. Cui, and L.L. Zhang: Adv. Mater. Res., 2011, vols. 299–300, pp. 616–20.

M.K. King: Proc. Combust. Inst., 2009, vol. 32, pp. 2107–14.

J. Chandradass and D.S. Bae: Mater. Manuf. Process., 2008, vol. 23, pp. 494–98.

J. Li, Y. Pan, C. Xiang, Q. Ge, and J. Guo: Ceram. Int., 2006, vol. 32, pp. 587–91.

C.A. Shaklee and G.L. Messing: J. Am. Ceram. Soc., 1994, vol. 77, pp. 2977–84.

M.K. Naskar: J. Am. Ceram. Soc., 2010, vol. 93, pp. 1260–63.

V.V. Karasev, A.A. Onischuk, O.G. Glotov, A.M. Baklanov, A.G. Maryasov, V.E. Zarko, V.N. Panfilov, A.I. Levykin, and K.K. Sabelfeld: Combust. Flame, 2004, vol. 138, pp. 40–54.

M.L. Panchula and J.Y. Ying: Nanostruct. Mater., 1997, vol. 9, pp. 161–64.

H. Goodshaw, J. Forrester, G. Suaning, and E. Kisi: J. Mater. Sci., 2007, vol. 42, pp. 337–45.

K.H. Tseng, C.Y. Liao, J.C. Huang, D.C. Tien, and T.T. Tsung: Mater. Lett., 2008, vol. 62, pp. 3341–44.

K.H. Tsenga, C.Y. Liaoa, and D.C. Tien: J. Alloys Compd., 2010, vol. 493, pp. 438–40.

K.H. Tseng and J.C. Huang: J. Nanopart. Res., 2011, vol. 13, pp. 2963–72.

M.M. Stoiljković and I. Holclajtner-Antunović: Contrib. Plasma Phys., 1997, vol. 37, pp. 459–68.

S. Roualdes, V. Rouessac, and J. Durand: Comprehens. Membr. Sci. Eng., 2010, vol. 1, pp. 159–97.

P.-L. Chang, F.-S. Yen, K.-C. Cheng, and H.-L. Wen: Nano Lett., 2001, vol. 1, pp. 253–61.

K. Sato, Y. Hotta, H. Yilmaz, K. Sato, and K. Watari: J. Colloid Interf. Sci., 2009, vol. 331, pp. 221–26.

H. Lü, B. Wang, and Q. Ban: Energ. Sources, Part A, 2010, vol. 32, pp. 1509–16.

A. Alemdar, O. Atici, and N. Gungor: Mater. Lett., 2000, vol. 43, pp. 57–61.

E.J.W. Verwey: J. Phys. Colloid Chem., 1947, vol. 51, pp. 631–66.

Acknowledgments

This work was supported by the National Science Council, Taiwan, R.O.C., under Grant No. NSC 99-2221-E-027-021.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted June 4, 2012.

Rights and permissions

About this article

Cite this article

Liao, CY., Tseng, KH. & Lin, HS. Preparation of Metallic Aluminum Compound Particles by Submerged Arc Discharge Method in Aqueous Media. Metall Mater Trans B 44, 91–97 (2013). https://doi.org/10.1007/s11663-012-9764-x

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-012-9764-x