Abstract

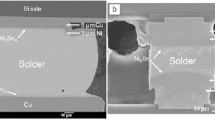

Metallurgical challenges in controlling the microstructural stability of Cu and solder microbumps in 3D IC packaging technology are discussed. Using uni-directional 〈111〉 oriented nanotwinned Cu, the controlled growth of oriented Cu66n5 on the nanotwinned Cu and its transformation to Cu3Sn without Kirkendall voids have been achieved. In order to join a stack of Si chips into a 3D device, multiple reflows of solder microbumps may be required; we consider localized heating to do so by the use of self-sustained explosive reaction in multi-layered Al/Ni thin films of nano thickness. It avoids re-melting of those solder joints which have been formed already in the 3D stacking structure.

Similar content being viewed by others

References

Lin J C, Chiou W C, Yang K F, et al. High density 3D integration using CMOS foundry technologies for 28 nm node and beyond. IEEE International Electron Devices Meeting (IEDM), 2010. 2.1.1–2.1.4

Yu A, Lau J H, Ho S W, et al. Study of 15 μm pitch solder microbumps for 3D IC integration. Electronic Components and Technology Conference (ECTC), 2009, 59. 6–10

Tu K N. Reliability challenges in 3D IC packaging technology. Microelectron Reliab, 2011, 51:517–523

Tu K N, Hsiao H Y, Chen C. Transition from flip chip solder joint to 3D IC microbump: Its effect on microstructure anisotropy. Microelectron Reliab, 2013, 53:2–6

Tian T, Chen K, Kunz M, et al. Preferred orientation of 30 μm fine pitch Sn2.5Ag micro-bumps studied by synchrotron polychromatic x-ray Laue microdiffraction. Electronic Components and Technology Conference (ECTC), 2012, 62. 882–885

Tu K N, Gusak A M. Kinetics in Nanoscale Materials. New York: Wiley, 2013

Mullins W W, Sekerka R F. Stability of a planar interface during solidification of a dilute binary alloy. J Appl Phys, 1964, 35:444–451

Hsiao H Y, Liu C M, Lin H W, et al. Unidirectional growth of microbumps on (111)-oriented and nanotwinned copper. Science, 2012, 336:1007–1010

Suh J O, Tu K N, Tamura N. Dramatic morphological change of scallop-type Cu66n5 formed on (001) single crystal copper in reaction between molten SnPb solder and Cu. Appl Phys Lett, 2007, 91: 051907

Zou H F, Yang H J, Zhang Z F. Morphologies, orientation relationships and evolution of Cu66n5 grains formed between molten Sn and Cu single crystals. Acta Mat, 2008, 56:2649–2662

Lu L, Shen Y, Chen X, et al. Ultrahigh strength and high electrical conductivity in copper. Science, 2004, 304:422–426

Lu L, Chen X, Huang X, et al. Revealing the maximum strength in nanotwinned copper. Science, 2009, 323:607–610

Anderoglu O, Misra A, Wang H, et al. Epitaxial nanotwinned Cu films with high strength and high conductivity. Appl Phys Lett, 2008, 93:083108

Anderoglu O, Misra A, Wang H, et al. Thermal stability of sputtered Cu films with nanoscale growth twins. J Appl Phys, 2008, 103:094322

Zeng K, Stierman R, Chiu T C, et al. Kirkendall void formation in eutectic SnPb solder joints on bare Cu and its effect on joint reliability. J Appl Phys, 2005, 97:024508

Juang J Y, Lu S T, Zhan C J, et al. Development of 30 μm pitch Cu/Ni/SnAg micro-bump-bonded chip-on-chip interconnections. Proc. IEEE IMPACT, 2010. 1–4

Ma E, Thompson C V, Clevenger L A, et al. Self-propagating explosive reaction in Al/Ni multilayer thin films. Appl Phys Lett, 1990, 57:1262–1264

Floro J A. Propagation of explosive crystallization in thin Rh-Si multilayer films. J Vac Sci Technol A-Vac Surf Films, 1986, 4:631–636

Clevenger L A, Thompson C V, Tu K N. Explosive silicidation in nickel/amorphous-silicon multilayer thin films. J Appl Phys, 1990, 67:2894–2898

Wickersham C E, Poole J E. Explosive crystallization in zirconium/ silicon multilayers. J Vac Sci Tech A-Vac Surf Films, 1988, 6:1699–1702

De Avillez R R, Clevenger L A, Thompson C V, et al. Quantitative investigation of Ti/amorphous-Si multilayer thin film reactions. J Mater Res, 1990, 5:593–600

Weihs T P. Handbooks of Thin Film Process Technology. Bristol, UK: Institute of Physics, 1998

Gavens A J, Van Heerden D, Mann A B, et al. Effect of intermixing on self-propagating exothermic reactions in Al/Ni nanolaminate foils. J Appl Phys, 2000, 87:1255–1263

Wang J, Besnoin E, Knio O M, et al. Investigating the effect of applied pressure on reactive multilayer foil joining. Acta Mat, 2004, 52:5265–5274

Tong M S, Sturgess D, Tu K N, et al. Solder joints fabricated by explosively reacting nanolayers. Appl Phys Lett, 2008, 92:144101

Author information

Authors and Affiliations

Corresponding author

Additional information

(on sabbatical leave from UCLA)

Rights and permissions

About this article

Cite this article

Tu, K.N., Tian, T. Metallurgical challenges in microelectronic 3D IC packaging technology for future consumer electronic products. Sci. China Technol. Sci. 56, 1740–1748 (2013). https://doi.org/10.1007/s11431-013-5261-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-013-5261-y