Abstract

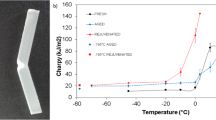

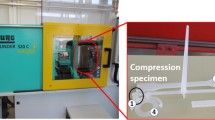

Three grades of polypropylene were tested in uniaxial compression at room temperature, across a wide range of strain rate: 10−4 s−1 to 104 s−1. One grade is a conventional polypropylene homopolymer. The two other grades are the polypropylene forming the matrix phase of a continuous glass fibre-reinforced thermoplastic composite prepreg, with and without blending with a carbon-black master batch. Tests at the highest strain rates were performed using a compression split Hopkinson pressure bar. The test specimens, for all the three rates, were imaged using appropriate digital cameras in order to observe the deformation process. In addition, the images obtained were analysed digitally to obtain true strain measurements for the medium rates category. All three grades of polypropylene showed pronounced strain-rate dependence of compressive yield stress, increasing by factors of up to 4 across the range of rates. At the lowest rates, there was close agreement between the yield stresses for all three materials, and also close agreement with the Eyring theory. Considering the highest strain rates, however, yield stresses increased more rapidly with log(strain-rate) than would be expected from a linear Eyring prediction and values for the three materials diverged. This was attributed to the contributions made in each material by both alpha and beta relaxation processes. Also prominent in the medium- and high-rate experimental results was pronounced post-yield strain softening, greatest at the highest strain-rates. This resulted from a combination of thermal softening from adiabatic heating, and structural rejuvenation as often seen in glassy polymers in quasi-static tests.

Similar content being viewed by others

References

Bassett, D.C.: Polymer spherulites: A modern assessment. J. Macromol. Sci., Phys. 42B(2), 227–256 (2003)

Bauwens, J.C.: Relation between the compression yield stress and the mechanical loss peak of bisphenol-A-polycarbonate in the β transition range. J. Mater. Sci. 7(5), 577–584 (1972)

Bauwens-Crowet, C.: The compression yield behaviour of polymethyl methacrylate over a wide range of temperatures and strain-rates. J. Mater. Sci. 8(7), 968–977 (1973)

Bauwens-Crowet, C., Bauwens, J.C.: Effect of thermal history on the tensile yield stress of polycarbonate in the transition range. Polymer 24(7), 921–924 (1983)

Bauwens-Crowet, C., Bauwens, J.C., Homès, G.: The temperature dependence of yield of polycarbonate in uniaxial compression and tensile tests. J. Mater. Sci. 7(2), 176 (1972)

Boyce, M.C., Haward, R.N.: The post yield deformation of glass polymers. In: Haward, R.N., Young, R.J. (eds.) The Physics of Glassy Polymers, p. 508. Chapman and Hall, London (1997)

Buckley, C.P., Harding, J., Hou, J.P., Ruiz, C., Trojanowski, A.: Deformation of thermosetting resins at impact rates of strain. Part I: Experimental study. J. Mech. Phys. Solids 49(7), 1517 (2001)

Buckley, C.P., Dooling, P.J., Harding, J., Ruiz, C.: Deformation of thermosetting resins at impact rates of strain. Part 2: constitutive model with rejuvenation. J. Mech. Phys. Solids 52(10), 2355–2377 (2004)

Chou, S.C., Robertson, K.D., Rainey, J.H.: The effect of strain rate and heat developed during deformation on the stress–strain curve of plastics. Exp. Mech. 13(10), 422–432 (1973)

Cogswell, F.N., Staniland, P.A.: Method of producing fibre-reinforced composition. EP0102159

Foot, J.S., Truss, R.W., Ward, I.M., Duckett, R.A.: The yield behaviour of amorphous polyethylene terephthalate: An activated rate theory approach. J. Mater. Sci. 22(4), 1437 (1987)

Gómez-del Río, T., Rodríguez, J.: Compression yielding of polypropylenes above glass transition temperature. Eur. Polym. J. 46(6), 1244–1250 (2010). doi:10.1016/j.eurpolymj.2010.02.016

Gorham, D.A.: A numerical method for the correction of dispersion in pressure bar signals. J. Phys. E, Sci. Instrum. 16(6), 477 (1983)

Gorham, D.A.: Specimen inertia in high strain-rate compression. J. Phys. D, Appl. Phys. 22(12), 1888 (1989)

Gorham, D.A.: Effect of specimen dimensions on high strain rate compression measurements of copper. J. Phys. D, Appl. Phys. 24(8), 1489 (1991)

Gray, G.T.: Classic split-Hopkinson pressure bar testing. In: ASM Handbook, vol. 8, p. 462 (2000)

Gray, G.T. III, Blumenthal, W.R., Medlin, D.: Split-Hopkinson pressure bar testing of soft materials. In: Medlin, D. (ed.) ASM Handbook: Materials Testing and Evaluation, vol. 8, p. 488. ASM International, Materials Park (2000)

GuritSuprem: Material Safety Data Sheet—PLYTRON: According to EC Directive 91/155/EEC. p. 1. GuritSuprem, Switzerland (2004)

GuritSuprem: Plytron—Product Description, Properties and Applications—A Technical Report. Gurit Composite Technologies, Switzerland (2005)

Harding, J., Noble, J.P.: An Extended Hopkinson-Bar Analysis. University Technology Centre, Department of Engineering Science, University of Oxford (1998)

Hartley, R.S., Cloete, T.J., Nurick, G.N.: An experimental assessment of friction effects in the split Hopkinson pressure bar using the ring compression test. Int. J. Impact Eng. 34(10), 1705 (2007)

Imperial Chemical Industries, L.: ‘Propathene’ Data for Design: Technical Service Note PP110. Vol. 3rd. Polypropylene Marketing, ICI Plastics Division, Welwyn Garden City, Herts (1979)

Kolsky, H.: An investigation of the mechanical properties of materials at very high rates of loading. Proc. Phys. Soc. B 62, 676 (1949)

McCrum, N.G., Read, B.E., Williams, G.: Anelastic and Dielectric Effects in Polymeric Solids. Wiley, London (1967)

Mettler-Toledo: Excellence XS Analytical Balances User Manual. Mettler-Toledo GmbH, Switzerland (2006)

Mulliken, A.D., Boyce, M.C.: Mechanics of the rate-dependent elastic-plastic deformation of glassy polymers from low to high strain rates. Int. J. Solids Struct. 43(5), 1331 (2006)

Natta, G., Pino, P., Corradini, P., Danusso, F., Mantica, E., Mazzanti, G., Moraglio, G.: Crystalline High Polymer of alpha-olefins. J. Am. Chem. Soc. 77(6), 1708 (1955)

Ree, T., Eyring, H., Eirich, F.R.: The relaxation theory of transport phenomena. In: Rheology: Theory and Applications, vol. 2, p. 83. Academic Press, New York (1958)

Reyes Villanueva, G., Cantwell, W.J.: The high velocity impact response of composite and FML-reinforced sandwich structures. Compos. Sci. Technol. 64(1), 35–54 (2004)

Rietsch, F., Bouette, B.: Compression yield behaviour of polycarbonate over a wide range of strain rates and temperatures. Eur. Polym. J. 26(10), 1071 (1990)

Roetling, J.A.: Yield stress behaviour of poly(ethyl methacrylate) in the glass transition region. Polymer 6(11), 615 (1965)

Savage, G.M., Tacon, K.P., Welsh, I.T.: Composite Armour Materials (1993)

Siviour, C.R., Walley, S.M., Proud, W.G., Field, J.E.: The high strain rate compressive behaviour of polycarbonate and polyvinylidene difluoride. Polymer 46(26), 12546–12555 (2005)

Trautmann, A., Siviour, C.R., Walley, S.M., Field, J.E.: Lubrication of polycarbonate at cryogenic temperatures in the split Hopkinson pressure bar. Int. J. Impact Eng. 31(5), 523 (2005)

Turner-Jones, A., Aizlewood, J.M., Beckett, D.R.: Crystalline forms of isotactic polypropylene. Makromol. Chem. 75(1), 134 (1964)

Walley, S.M., Field, J.E., Pope, P.H.: Strain rate sensitivity of polymers in compression from low to high rates. DYMAT J. 1(3), 211–227 (1994)

Walley, S.M., Field, J.E., Pope, P.H., Safford, N.A.: A study of the rapid deformation behaviour of a range of polymers. Philos. Trans. R. Soc. Lond. Ser. A, Math. Phys. Sci. 328(1597), 1–33 (1989)

Wang, Y., Arruda, E.M.: Constitutive modeling of a thermoplastic olefin over a broad range of strain rates. J. Eng. Mater. Technol. 128(4), 551 (2006)

Williamson, D.M., et al.: Temperature–time response of a polymer bonded explosive in compression (EDC37). J. Phys. D, Appl. Phys. 41(8), 085404 (2008)

Zhao, H., Gary, G.: A new method for the separation of waves. Application to the SHPB technique for an unlimited duration of measurement. J. Mech. Phys. Solids 45(7), 1185 (1997)

Acknowledgements

The authors are grateful to Cristophe Bourban of Gurit Suprem, Switzerland, for providing the PLW and PLB grades of polypropylene used in this study. The authors also appreciate the help of colleagues—Jens Wiegand, Nik Petrinic, Robert Gerlach—in analysing SHPB results as well as the help of Neil Warland, Richard Froud and Richard Duffin in preparing test specimens and setting up the camera. The Cordin 550 high-speed camera was provided by the EPSRC Engineering Instrument Pool, we are particularly grateful to A. Walker for his advice and support while using this camera.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Okereke, M.I., Buckley, C.P. & Siviour, C.R. Compression of polypropylene across a wide range of strain rates. Mech Time-Depend Mater 16, 361–379 (2012). https://doi.org/10.1007/s11043-012-9167-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11043-012-9167-z