Abstract

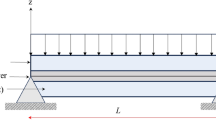

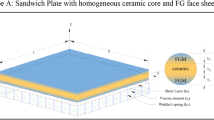

This work presents a multiscale model of viscoelastic constrained layer damping treatments for vibrating plates/beams. The approach integrates a finite element (FE) model of macroscale vibrations and a micromechanical model to include effects of microscale structure and properties. The FE model captures the shear deformation of the viscoelastic core, rotary inertial effects of all layers, and viscoelastic boundaries of the plate. Comparison with analytical and FE results validates the proposed FE model. A self-consistent (SC) model makes the micro to macro scale transition to approximate the effective behavior a heterogeneous core. Modal damping resulting from the presence of voids and negative stiffness regions in the core material is modeled. Results show that negative stiffness regions in the viscoelastic core material, even at low volume fractions, yield superior macroscopic damping behavior. The coupled SC and FE models provide a powerful multiscale predictive design tool for sandwich beams and plates.

Similar content being viewed by others

References

Ashbey, M.F.: Materials Selection in Mechanical Design. Butterworth-Heinmann, Oxford (1999)

Austin, E.M.: Variations on modeling of constrained-layer damping treatments. Shock Vib. Dig. 31(4), 275–280 (1999)

Azrar, L., Boutyour, E.H., Potier-Ferry, M.: Non-linear forced vibrations of plates by an asymptotic-numerical method. J. Sound Vib. 252(4), 657–674 (2002)

Bathe, K.J.: Finite Element Procedures in Engineering Analysis. Prentice-Hall (1982)

Berveiller, M., Fassi-Fehri, O., Hihi, A.: The problem of two plastic and heterogeneous inclusions in an anisotropic medium. Int. J. Eng. Sci. 25(6), 691–709 (1987)

Budiansky, B.: On the elastic moduli of some heterogeneous materials. J. Mech. Phys. Solids 13(4), 223–227 (1965)

Chen, X., Chen, H.L., Hu, Le: Damping prediction of sandwich structures by order-reduction-iterative approach. J. Sound Vib. 222(5), 803–812 (1999)

Cherkaoui, M., Sabar, H., Berveiller, M.: Micromechanical approach of the coated inclusion problem and applications to composite materials. J. Eng. Mater. Technol. 116, 274–278 (1994)

Cherkaoui, M., Sabar, H., Berveiller, M.: Elastic composites with coated reinforcements: a micromechanical approach for nonhomothetic topology. Int. J. Eng. Sci. 33(6), 829–843 (1995)

Chia, C.Y.: Nonlinear Analysis of Plates. McGraw-Hill, New York (1980)

Choi, H.J., Austin, R., Allen, J.K., McDowell, D.L., Mistree, F.: An approach for robust design of reactive powder metal mixtures based on non-deterministic micro-scale shock simulation. J. Comput. Aided Mater. Des. 12(1), 57–85 (2005)

Christensen, R.M.: Mechanics of Composite Materials. Dover Publications, Inc., Mineola (2005a)

Christensen, R.M.: Theory of viscoelasticity. Dover Publications, Inc., Mineola (2005b)

Cupial, P., Niziol, J.: Vibration and damping analysis of thee-layer composite plate with viscoelastic mid-layer. J. Sound Vib. 183(1), 99–114 (1995)

Daya, E.M., Potier-Ferry, M.: A numerical method for nonlinear eigenvalue problems application to vibrations of viscoelastic structures. Comput. Struct. 79, 533–541 (2001)

Daya, E.M., Potier-Ferry, M.: A shell finite element for visoelastically damped sandwich structures. Revue européenne des éléments finis 11(1), 39–56 (2002)

Daya, E.M., Azrar, L., Potier-Ferry, M.: Modélisation par éléments finis des vibrations non-linéaires des plaques sandwich viscoélastiques. Mécanique & Industries 6, 13–20 (2005)

Dhatt, G., Touzot, G., Lefrançois, E.: Méthode des éléments finis––Une présentation. Hermes Sciences Publications, Lavoisier, Paris, France (2005) [ISBN 2746209799]

Ditaranto, R.A., Blasingame, W.: Composite damping of vibrating beams. J. Eng. Ind. 89(B), 633–638 (1967)

DiTaranto, R.A., McGraw, Jr., J.R.: Vibratory bending of damped laminated plates. J. Eng. Ind. 91, 1081–1090 (1969)

Duigou, L., Daya, E.M., Potier-Ferry, M.: Iterative algorithms for non-linear eigenvalue problems. Application to vibrations of viscoelastic shells. Comput. Methods Appl. Mech. Eng. 192, 1323–1335 (2003)

Faulk, F.: Ginzburg-landau theory of static domain walls in shape memory alloys. Zeitschrift für Physik 51(B), 177–185 (1983)

Ferry, J.D.: Viscoelastic Properties of Polymers, 2nd edn. Wiley (1970)

Haberman, M.: Vers la conception des matériaux amortissants: une approche micromécanique. Ph.D. thesis, Université Paul verlaine-Metz (2006)

Haberman, M., Berthelot, Y., Cherkaoui, M.: Transmission loss of viscoelastic materials containing oriented, ellipsoidal, coated microinclusions. J. Acoust. Soc. Am. 118(5), 2984–2992 (2005)

Haberman, M., Berthelot, Y., Cherkaoui, M.: Micromechanical modeling of particulate composites for damping of acoustic waves. J. Eng. Mater. Technol. 128, 320–329 (2006)

Harris, C.M.: Shock and Vibration Handbook. McGraw-Hill, New York (1988)

Hashin, Z., Shtrikman, S.: A variational approach to the theory of the elastic behavior of multi-phase materials. J. Mech. Phys. Solids 11, 127–140 (1963)

Havriliak, S., Negami, S.: A complex plane analysis of α-dispersions in some polymer systems. J. Polym. Sci.: Part C 14, 99–117 (1966)

Hill, R.: A self-consistent mechanics of composite materials. J. Mech. Phys. Solids 13, 213–222 (1965)

Jarzynski, J.: A review of the mechanisms of sound attenuation in materials. In: Corsaro, R.D., Sperling, L.H. Sound and Vibration Damping with Polymers, vol. 424, pp. 116–207. American Chemical Society, Washington (1990)

Johnson, C.D., Kienholz, D.A.: Finite element prediction of damping in beams with constrained viscoelastic layer. Shock Vib. Bull. 51(1), 71–81 (1981)

Kang, K.H., Kim, K.J.: Vibration analysis of beam and plate with viscoelastic boundary supports. In: Asia–Pacific Vibration Conference, Kuala Luper, Malaysia (1996)

Kerwin, E.M.: Damping of flexural waves by a constrained viscoelastic layer. J. Acoust. Soc. Am. 31(7), 952–962 (1959)

Lakes, R.S.: Extreme damping in compliant composites with a negative stiffness phase. Philos. Mag. Lett. 81, 95–100 (2001a)

Lakes, R.S.: Extreme damping in composite materials with a negative stiffness phase. Phys. Rev. Lett. 86, 2897–2900 (2001b)

Lakes, R.S., Drugan, W.J.: Dramatically stiffer elastic composite materials due to a negative stiffness phase? J. Mech. Phys. Solids 50, 979–1009 (2002)

Lakes, R.S., Lee, T., Bersie, A., Wang, Y.C.: Extreme damping in composite materials with negative stiffness inclusions. Nature 410, 565–567 (2001)

Lilly, J.G.: Recent advances in acoustical glazing. Sound Vib. 38(2), 8–13 (2004)

Lu, Y.P., Killian, J.W., Everstine, G.C.: Vibrations of three layered damped sandwich plate composites. J. Sound Vib. 64, 63–71 (1979)

McDowell, D.L., Story, T.L.: New directions in materials design science and engineering (mds & e). Tech. rep., U.S. National Science Foundation Workshop Report: Georgia Institute of Technology Materials Council, Atlanta, GA (1999)

Mead, D.J., Markus, S.: The forced vibration of three-layer damped sandwich beam with arbitrary boundary conditions. J. Sound Vib. 10, 163–175 (1969)

Mistree, F., Hughes, O.F., Bras, B.: Compromise decision support problem and the linear adaptive programming algrothim, in structural optimization: status and promise. In: Kamat, M.P. (ed.) Progress in Astronautics and Aeronautics, chap. 11, AIAA, Washington, DC (1993)

Moore, T.C., Lovins, A.B.: Vehicle design strategies to meet and exceed pngv goals. In: Costa Mesa, CA: Society of Automotive Engineers (ed.) SAE Future Transportation Technology Conference (1995)

Olsen, G.B.: Designing a new material world. Science 288(5468), 993–998 (2000)

Papakonstantopoulos, G.J., Yoshimoto, K., Doxastakis, M., Nealey, P.F., de Pablo, J.J.: Local mechanical properties of polymeric nanocomposites. Phys. Rev. E 031801, 1–6 (2005)

Rikards, R., Chate, A., Barkanov, E.: Finite element analysis of damping the vibrations of laminated composites. Comput. Struct. 46(6), 1005–1015 (1993)

Ross, D., Ungar, E.E., Kerwin, E.M.: Damping of plate flexural vibrations by means of viscoelastic laminae. In: American Society of Mechanical Engineers: Atlantic City, New Jersy (ed.) Structural Damping, pp 49–87. ASME Annual Meeting, A.S.o.M. Engineers (1959)

Sainsbury, M.G.: Experimental and theoretical techniques for the vibration analysis of damped complex structures. Ph.D. thesis, Imperial College of Science and Technology, University of London (1973)

Sainsbury, M.G., Ewins, D.J.: Vibration analysis of a damped machinery foundation structure using the dynamic stiffness coupling technique. J. Eng. Ind. Trans. ASME 1000–1005 (1974)

Soni, M.L.: Finite element analysis of viscoelastically damped sandwich structures. Shock Vib. Bull. 55(1), 97–109 (1981)

Ungar, E.E.: Structural damping. In: Beranek, L.L., Vér I.L. (eds.) Noise and Vibration Control Engineering: Principles and Applications, pp. 1–2. Wiley-Interscience, Hoboken (1992)

Xhang, Q.J.: Finite element analysis of additive damping structures. In: Proceedings of the 13th International Modal Analysis Conference, 1006–1010 (1994)

Yan, M.J., McDowell, E.H.: Governing equations for vibrating constrained-layer damping sandwich plates and beams. J. Appl. Mech. 94, 1041–1047 (1972)

Yoshimoto, K., Jain, T.S., Van Workum, K., Nealey, P.F., de Pablo, J.J.: Mechanical heterogeneities in model polymer glasses at small length scales. Phys. Rev. Lett. 93(17), 175501 (2004)

Zhang, Q.J., Sainsbury, M.G.: The galerkin element method applied to the vibration of rectangular damped sandwich plates. Comput. Struct. 74, 717–730 (2000)

Acknowledgements

M. Haberman gratefully acknowledges financial support of the Conseil Régional de Lorraine in France and the support of an internal research and development fund from the Applied Research Laboratories at the University of Texas at Austin.

Author information

Authors and Affiliations

Corresponding author

Appendix: Elements mass and stiffness matrices and other defined matrices

Appendix: Elements mass and stiffness matrices and other defined matrices

The finite element matrices defined in Eqs. 18, and 20 are defined as follows:

Writing Eqs. 3, 6, and 7, terms in Eq. 28 yields the following expressions:

The other terms in Eqs. 29 and 30 are the classical shape functions employed in Sect. 2.5 (Dhatt et al. (2005)).

Rights and permissions

About this article

Cite this article

Koutsawa, Y., Haberman, M.R., Daya, E.M. et al. Multiscale design of a rectangular sandwich plate with viscoelastic core and supported at extents by viscoelastic materials. Int J Mech Mater Des 5, 29–44 (2009). https://doi.org/10.1007/s10999-008-9084-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10999-008-9084-0