Abstract

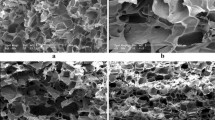

The aim of this study was to fabricate three-dimensional (3D) porous chitosan/poly(ε-caprolactone) (PCL) hydrogels with improved mechanical properties for tissue engineering applications. A modified emulsion lyophilisation technique was developed to produce 3D chitosan/PCL hydrogels. The addition of 25 and 50 wt% of PCL into chitosan substantially enhanced the compressive strength of composite hydrogel 160 and 290%, respectively, compared to pure chitosan hydrogel. The result of ATR–FTIR imaging corroborated that PCL and chitosan were well mixed and physically co-existed in the composite structures. The composite hydrogels were constructed of homogenous structure with average pore size of 59.7 ± 14 μm and finer pores with average size of 4.4 ± 2 μm on the wall of these larger pores. The SEM and confocal laser scanning microscopy images confirmed that fibroblast cells were attached and proliferated on the 3D structure of these composite hydrogels. The composite hydrogels acquired in this study possessed homogeneous porous structure with improved mechanical strength and integrity. They may have a high potential for the production of 3D hydrogels for tissue engineering applications.

Similar content being viewed by others

References

Khademhosseini A, Langer R. Microengineered hydrogels for tissue engineering. Biomaterials. 2007;28(34):5087–92.

Ma PX. Biomimetic materials for tissue engineering. Adv Drug Deliv Rev. 2008;60(2):184–98.

Sarasam A, Madihally SV. Characterization of chitosan-polycaprolactone blends for tissue engineering applications. Biomaterials. 2005;26(27):5500–8.

Wan Y, Wu H, Cao X, Dalai S. Compressive mechanical properties and biodegradability of porous poly(caprolactone)/chitosan scaffolds. Polym Degrad Stab. 2008;93(10):1736–41.

Gallico GG, 3rd, O’Connor NE, Compton CC, Remensnyder JP, Kehinde O, Green H. Cultured epithelial autografts for giant congenital nevi. United States: Shriners Burns Institute, Boston; 1989.

Suh JK, Matthew HW. Application of chitosan-based polysaccharide biomaterials in cartilage tissue engineering: a review. Biomaterials. 2000;21(24):2589–98.

Madihally SV, Matthew HWT. Porous chitosan scaffolds for tissue engineering. Biomaterials. 1999;20(12):1133–42.

Averousa L, Moro L, Dole P, Fringant C. Properties of thermoplastic blends: starch-polycaprolactone. Polymer. 2000;41:4157–67.

Zhu H, Ji J, Lin R, Gao C, Feng L, Shen J. Surface engineering of poly(d, l-lactic acid) by entrapment of chitosan-based derivatives for the promotion of chondrogenesis. J Biomed Mater Res. 2002;62(4):532–9.

Kweon HY, Yoo MK, Park IK, Kim TH, Lee HC, Lee HS, et al. A novel degradable polycaprolactone networks for tissue engineering. Biomaterials. 2003;24:801–8.

Garcia Cruz DM, Coutinho DF, Mano JF, Gomez Ribelles JL, Salmeron Sanchez M. Physical interactions in macroporous scaffolds based on poly(ε-caprolactone)/chitosan semi-interpenetrating polymer networks. Polymer. 2009;50(9):2058–64.

Wan Y, Xiao B, Dalai S, Cao X, Wu Q. Development of polycaprolactone/chitosan blend porous scaffolds. J Mater Sci Mater Med. 2009;20:719–24.

Honma T, Senda T, Inoue Y. Thermal properties and crystallization behaviour of blends of poly(ε-caprolactone) with chitin and chitosan. Polym Int. 2003;52:1839–46.

Sarasam AR, Samli AI, Hess L, Ihnat MA, Madihally SV. Blending chitosan with polycaprolactone: porous scaffolds and toxicity. Macromol Biosci. 2007;7(9–10):1160–7.

She H, Xiao X, Liu R. Preparation and characterization of polycaprolactone-chitosan composites for tissue engineering applications. J Mater Sci. 2007;42(19):8113–9.

Mohan N, Nair PD. Polyvinyl alcohol-poly(caprolactone) semi IPN scaffold with implication for cartilage tissue engineering. J Biomed Mater Res Part B Appl Biomater. 2007;84:584–94.

Van der Weerd J, Chan K, Kazarian SG. An innovative design of compaction cell for in situ FTIR imaging of tablet dissolution. Vib Spectrosc. 2004;35:9–13.

Kazarian SG, Chan KLA. Micro- and macro-attenuated total reflection Fourier transform infrared spectroscopic imaging. Appl Spectrosc. 2010;64:135A–52A.

Palombo F, Weinberg PD, Kazarian SG. Measurement of drug and macromolecule diffusion across atherosclerotic rabbit aorta ex vivo by attenuated total reflection-fourier transform infrared imaging. J Biomed Opt 2009; 14: 044008.

Dehghani F, Annabi N, Valtchev P, Mithieux SM, Weiss AS, Kazarian SG, et al. Effect of dense gas CO2 on the coacervation of elastin. Biomacromolecules. 2008;9:1100–5.

Chan K, Govada L, Bill R, Chayen N, Kazarian SG. Attenuated total reflection-FTIR spectroscopic imaging of protein crystallization. Anal Chem. 2009;81:3769–75.

Xu Q, Nakajima M, Ichikawa S, Nakamura N, Shiin T. A comparative study of microbubble generation by mechanical agitation and sonication. Innov Food Sci Emerg. 2008;9:489–94.

Arirachakaran S, Oglesby KD, Malinowsky MS, Shoham O, Brill JP. An analysis of oil/water flow phenomena in horizontal pipes. SPE Production Operations Symposium Oklahoma City, 1989.

Yeo LY, Matar OK, Perez Susana, de Ortiz E, Hewitt GF. A description of phase inversion behaviour in agitated liquid–liquid dispersions under the influence of the Marangoni effect. Chem Eng Sci. 2002;57:3505–20.

Seol YJ, Lee JY, Park YJ, Lee YM, Ku Y, Rhyu IC, et al. Chitosan sponges as tissue engineering scaffolds for bone formation. Biotechnol Lett. 2004;26(13):1037–41.

Doillon C, Whyne C, Brandwein S, Silver F. Collagen-based wound dressings: control of the pore structure and morphology. J Biomed Mater Res. 1986;20:1219–28.

O’Brien FJ, Harley BA, Yannas IV, Gibson LJ. The effect of pore size on cell adhesion in collagen-GAG scaffolds. Biomaterials. 2005;26(4):433–41.

Jain S, Bates F. On the origins of morphological complexity in block copolymer surfactants. Science. 2003;300:460–4.

Osman Z, Arof AK. FTIR studies of chitosan acetate based polymer electrolytes. Electrochim Acta. 2003;48(8):993–9.

Senda T, He Y, Inoue Y. Biodegradable blends of poly(ε-caprolactone) with α-chitin and chitosan: specific interactions thermal properties and crystallization behaviour. Polym int. 2001;51:33–9.

Sarasam AR, Krishnaswamy R, Madihally S. Blending chitosan with polycaprolactone: effects on physicochemical and antibacterial properties. Biomacromolecules. 2006;7:1131–8.

Forsberg F, Liu J, Patel M, Liu L, Lin L, Solis C, et al. Preclinical acute toxicology study of surfactant-stabilized ultrasound contrast agents in adult rats. Int J Toxicol. 2010;29:32–9.

Chavda H, Patel C. Preparation and characterization od swellable polymer-based superporous hydrogel composite of poly(acrylamide-co-acrylic acid). Trends Biomater Artif Organs. 2010;24:83–9.

Karasulu H. Microemulsions as novel drug carriers: the formation, stability, applications and toxicity. Expert Opin Drug Deliv. 2008;5:119–35.

Kathuria N, Tripathi A, Kar KK, Kumar A. Synthesis and characterization of elastic and macroporous chitosan-gelatin cryogels for tissue engineering. Acta Biomater. 2009;5:406–18.

Tan H, Chu Constance R, Payne KA, Marra Kacey G. Injectable in situ forming biodegradable chitosan-hyaluronic acid based hydrogels for cartilage tissue engineering. Biomaterials. 2009;30:2499–506.

Huang Y, Onyeri S, Siewe M, Moshfeghian A, Madihally SV. In vitro characterization of chitosan-gelatin scaffolds for tissue engineering. Biomaterials. 2005;26(36):7616–27.

Hatson W, Shields J, Wilkinson P. Lymphocyte locomotion and attachment on two-dimensional surfaces and in three-dimensional matrices. J Cell Biol. 1982;92:747–52.

Berry CC, Campbell G, Spadiccino A, Robertson M, Curtis ASG. The influence of microscale topography on fibroblast attachment and motility. Biomaterials. 2004;25:5781.

Acknowledgment

The authors acknowledge the support of Miss Tsun Ting Lo for carrying a part of experimental study and financial support from ARC Grant no. DP0988545.

Author information

Authors and Affiliations

Corresponding author

Additional information

Xia Zhong and Chengdong Ji contributed equally and share the first authorship.

Rights and permissions

About this article

Cite this article

Zhong, X., Ji, C., Chan, A.K.L. et al. Fabrication of chitosan/poly(ε-caprolactone) composite hydrogels for tissue engineering applications. J Mater Sci: Mater Med 22, 279–288 (2011). https://doi.org/10.1007/s10856-010-4194-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10856-010-4194-2