Abstract

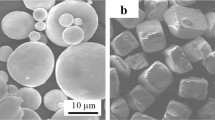

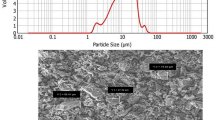

A clean powder metallurgy route was developed here to produce Ti foams, using a fugitive polymeric filler, polypropylene carbonate (PPC), to create porosities in a metal-polymer compact at the pre-processing stage. The as-produced foams were studied by scanning electron microscopy (SEM), LECO combustion analyses and X-ray diffraction (XRD). Compression tests were performed to assess their mechanical properties. The results show that titanium foams with open pores can be successfully produced by the method. The compressive strength and modulus of the foams decrease with an increasing level of porosity and can be tailored to those of the human bones. After alkali treatment and soaking in a simulated body fluid (SBF) for 3 days, a thin apatite layer was formed along the Ti foam surfaces, which provides favourable bioactive conditions for bone bonding and growth.

Similar content being viewed by others

References

G. Ryan, A. Pandit, D.P. Apatsidis, Biomaterials 27, 2651 (2006)

S.J. Simske, R.A. Ayers, T.A. Bateman, Mater. Sci. Forum 250, 151 (1997)

C.E. Wen, Y. Yamada, K. Shimojima, Y. Chino, H. Hosokawa, M. Mabuchi, J. Biomed. Mater. Res. 17, 2633 (2002)

L.D. Zardiackas, D.E. Parsell, L.D. Dillon, D.W. Mitchell, L.A. Nunnery, R. Poggie, J. Biomed. Mater. Res. 58, 180 (2001)

T.M. Freyman, I.V. Yannas, L.J. Gibson, Prog. Mater. Sci. 46, 273 (2001)

C.E. Wen, M. Mabuchi, Y. Yamada, K. Shimojima, Y. Chino, T. Asahina, Scripta Mater. 45, 1147 (2001)

Y. Zhang, H.H.K. Xu, S. Takagi, J. Mater. Sci. Mater. Med. 17, 437 (2006)

D.W. Hutmacher, Biomaterials 21, 2529 (2000)

X. Liu, P.X. Ma, Ann. Biomed. Eng. 32, 477 (2004)

H. Yoshikawa, A. Myoui, J. Artif. Organs 8, 131 (2005)

M. Kellomaki, H. Niiranen, K. Puumanen, N. Ashammakhi, T. Waris, P. Tormala, Biomaterials 21, 2495 (2000)

D. Kuroda, M. Niinomi, M. Morinaga, Y. Kato, T. Yashiro, Mater. Sci. Eng. A243, 244 (1998)

W.F. Ho, C.P. Ju, C.H. Chern Lin, Biomaterials 20, 2115 (1999)

D. M. Brunette, P. Tengvall, M. Textor, P. Thomsen, Titanium in Medicine (Springer-Verlag, Berlin, 2001)

D.C. Dunand, Adv. Eng. Mater. 6, 369 (2004)

J. Banhart, Prog. Mater. Sci. 46, 559 (2001)

R. Ricceri, F. Arcuri, P. Matteazzi, J. Phys. IV 11, 51 (2001)

R. Ricceri, P. Matteazzi, Int. J. Powder Metall. 39, 53 (2003)

J.P. Li, S.H. Li, K. de Groot, P. Layrolle, Key Eng. Mater. 218–220, 51 (2002)

C.S.Y. Jee, N. Ozguven, Z.X. Guo, J.R.G. Evans, Metall. Mater. Trans. B 31B, 1345 (2000)

Z.X. Guo, C.S.Y. Jee, N. Ozguven, J.R.G. Evans, Mater. Sci. Tech. 16, 776 (2000)

C. M. Schwanke, L. Schaeffer, Advanced powder technology (Trans Tech., Zurich, 1999) p. 190

S. Fujibayashi, T. Nakamura, S. Nishiguchi, J. Tamura, M. Uchida, H.M. Kim, T. Kokubo, J. Biomed. Mater. Res. 56, 562 (2001)

M. Wei, H.M. Kim, T. Kokubo, J.H. Evans, Mater. Sci. Eng. C 20, 125 (2002)

F. Liang, L. Zhou, K. Wang, Surf. Coat. Technol. 165, 133 (2003)

S. Fujibayashi, M. Neo, H.M. Kim, T. Kokubo, T. Nakamura, Biomaterials 25, 443 (2004)

S.A. Hacking, E.J. Harvey, M. Tanzer, J.J. Krygier, J.D. Bobyn, J. Bone Joint Surg. 85B, 1182 (2003)

M. Takemoto, S. Fujibayashi, M. Neo, J. Suzuki, T. Matsushita, T. Kokubo, T. Nakamura, Biomaterials 27, 2682 (2006)

T. Kokubo, H.M. Kim, M. Kawashita, T. Nakamura, J. Mater. Sci. Mater. Med. 15, 99 (2004)

A. Oyane, H.M. Kim, T. Furuya, T. Kokubo, T. Miyazaki, T. Nakamura, J. Biomed. Mater. Res. 65A, 188 (2003)

N.R.F. Beeley, Development of a novel powder coated fibre pre-processing route for cost effective production of metal matrix composites. PhD Thesis, Queen Mary, University of London, London, 2002

K.T. Bowers, J.C. Keller, B.A. Randolph, D.G. Wick, C.M. Michaels, Int. J. Oral Maxillofac. Implants 7, 302 (1992)

J. D. Currey, Bones: Structure and Mechanics (Princeton Univeristy Press, Princeton, 2002)

H.B. Wen, J.R. de Wijn, K. de Groot, J. Biomed. Mater. Res. 41, 227 (1998)

M. Uchida, H.M. Kim, T. Kokubo, S. Fujibayashi, T. Nakamura, J. Biomed. Mater. Res. 63, 522 (2002)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hong, T.F., Guo, Z.X. & Yang, R. Fabrication of porous titanium scaffold materials by a fugitive filler method. J Mater Sci: Mater Med 19, 3489–3495 (2008). https://doi.org/10.1007/s10856-008-3527-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10856-008-3527-x