Abstract

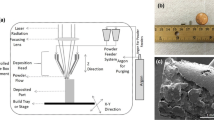

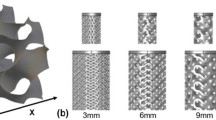

Fabrication of net shape load bearing implants with complex anatomical shapes to meet desired mechanical and biological performance is still a challenge. In this article, an overview of our research activities is discussed focusing on application of Laser Engineered Net Shaping (LENS™) toward load bearing implants to increase in vivo life time. We have demonstrated that LENS™ can fabricate net shape, complex metallic implants with designed porosities up to 70 vol.% to reduce stress-shielding. The effective modulus of Ti, NiTi, and other alloys was tailored to suit the modulus of human cortical bone by introducing 12–42 vol.% porosity. In addition, laser processed porous NiTi alloy samples show a 2–4% recoverable strain, a potentially significant result for load bearing implants. To minimize the wear induced osteolysis, unitized structures with functionally graded Co–Cr–Mo coating on porous Ti6Al4V were also made using LENS™, which showed high hardness with excellent bone cell–materials interactions. Finally, LENS™ is also being used to fabricate porous, net shape implants with a functional gradation in porosity characteristics.

Similar content being viewed by others

References

A. Sargeant, T. Goswami, Mater. Des. 27, 287 (2006)

B.V. Krishna, S. Bose, A. Bandyopadhyay, Acta Biomater. 3, 997 (2007)

W. Xue, B.V. Krishna, S. Bose, A. Bandyopadhyay, Acta Biomater. 3, 1007 (2007)

M. Assad, F. Likibi, P. Jarzem, M.A. Leroux, C. Coillard, CH.-H. Rivard, Mat.-wiss. u. Werkstofftech. 35, 219 (2004)

S.A. Shabalovskaya, Biomed. Mater. Eng. 12, 69 (2002)

I.H. Oh, N. Nomura, N. Masahashi, S. Hanada, Scr. Mater. 49, 1197 (2003)

R.M. Pillar, Int. J. Powder Metall. 34, 33 (1988)

C.E. Wen, M. Mabuchi, Y. Yamada, K. Shimojima, Y. Chino, T. Asahina, Scr. Mater. 45, 1147 (2001)

K. Otsuka, C.M. Wayman, in Shape Memory Materials (Cambridge University Press, Cambridge 1998)

L. Korne, J. Mentz, M. Bram, H. Buchkremer, D. Stover, M. Wagner, G. Eggeler, D. Christ, S. Reese, D. Bogdanski, M. Koller, S.A. Esenwein, G. Muhr, O. Prymak, M. Epple, Adv. Eng. Mater. 7, 613 (2005)

S. Wu, C.Y. Chung, X. Liu, P.K. Chu, J.P.Y. Ho, C.L. Chu, Y.L. Chan, K.W.K. Yeung, W.W. Lu, K.M.C. Cheung, K.D.K. Luk, Acta Mater. 55, 3437 (2007)

H.G. Willert, H. Bertram, G.H. Buchhorn, Clin. Orthop. Relat. Res. 258, 95 (1990)

A.A. Edidin, C.M. Rimnac, V.M. Goldberg, S.M. Kurtz, Wear 250, 152 (2001)

M. Jacobs, R. Gorab, D. Mattingly, L. Trick, C. Southworth, J. Arthroplasty 19(7), Suppl. 2, 48 (2004)

W. Pompe, H. Worch, M. Epple, W. Friess, M. Gelinsky, P. Greil, U. Hempel, D. Scharnweber, K. Schulte, Mater. Sci. Eng. A 362, 40 (2003)

R.J. Narayan, L.W. Hobbs, C. Jin, A. Rabiei, JOM 58(7), 56 (2006)

B.V. Krishna, S. Bose, A. Bandyopadhyay, Metall. Mater. Trans. A 38A, 1096 (2007)

C. Greiner, S.M. Oppenheimer, D.C. Dunand, Acta Biomater. 1, 705 (2005)

B.V. Krishna, W. Xue, S. Bose, A. Bandyopadhyay, Acta Biomater. 3, 697 (2008)

A. Chiba, K. Kumagai, N. Nomura, S. Miyakawa, Acta Mater. 55, 1309 (2007)

Acknowledgments

Authors would like to acknowledge financial support from the Office of Naval Research under the grant number N00014-1-05-0583. We also like to acknowledge financial support from the W. M. Keck Foundation for establishing a Biomedical Materials Research Lab at WSU.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bandyopadhyay, A., Krishna, B.V., Xue, W. et al. Application of Laser Engineered Net Shaping (LENS) to manufacture porous and functionally graded structures for load bearing implants. J Mater Sci: Mater Med 20 (Suppl 1), 29–34 (2009). https://doi.org/10.1007/s10856-008-3478-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10856-008-3478-2