Abstract

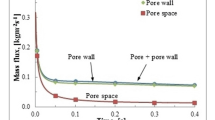

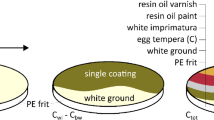

Thermal conductivity of paper coatings is increasingly important in the performance of many printing processes, including traditional heatset web offset and thermal papers, as well as digital processes, such as electrophotography. This work studies the extension of a Modified Lumped Parameter Model, previously used successfully to describe talc coatings, to model the thermal conductivity–coating structure relationships of calcium carbonate (gcc: 60 wt% < 2 μm) coatings. A series of compact tablets were used to provide experimental values of thermal diffusivity and conductivity. The samples studied covered a range of latex binder addition levels, namely 0–25 parts, based on 100 parts pigment, of 0.2 μm styrene acrylate latex. Combining the observed thermal properties with knowledge of the pore structure changes induced by the latex addition, it is possible to establish initial correlation with the model, in which the connectivity of the structure is increased at low latex dose illustrating the initial increase in effective thermal conductivity. The practically hard sphere properties of the latex used, combined with the broad size distribution of the gcc, produce a disruptive packing effect as the dose level increases, such that the conductivity reflects a competition between the increasing connectivity provided by the latex versus the increasing relative pore size in the network structure. It is recognized that the fixed pigment volume in the model unit cell diverts from a true representation of the residual porosity. At the highest latex dose levels, the intrinsically less conducting properties of the latex begin to dominate.

Similar content being viewed by others

Notes

Hydrocarb 60 is a registered trademark of Omya AG.

Acronal S360D is a registered trademark of the BASF AG.

Catiofast CS is a registered trademark of the BASF AG.

References

Maijala J, Putkisto K, Pietikäinen R, Grön J (2004) Nordic Pulp Paper Res J 19(3):291

Kartovaara I, Rajala R, Luukkala M, Sipi K (1985) Conduction of heat in paper, paper making raw materials, Trans 8th fundamental research symposium, Oxford, Mechanical Engineering Publications Ltd, London, pp 381–412

Hestmo RH, Lamvik M (2002) J Pulp Paper Sci 28(4):128

Crotogino RH (1982) Tappi J, October, pp 97–101

Cody HM (2005) Coated paper markets post strong rebound, PaperAge, Mar/Apr, pp 18–19

Tsotsas E, Martin H (1987) Chem Eng Process 22:19

Gane PAC, Ridgway CJ, Schölkopf J, Bousfield DW (2006) Heat transfer through calcium carbonate-based coating structures: observation and model for a thermal fusing process. Paper presented at the International Printing and Graphic Arts Conference, Cincinnati, Tappi Press

Maxwell JC (1873) A treatise on electricity and magnetism. Clarendon Press, Oxford, p 365

Gerstner P, Paltakari J, Gane PAC A lumped parameter model for thermal conductivity of paper coatings, Transp. Porous Media (in press). doi:https://doi.org/10.1007/s11242-008-9276-y

Hsu CT, Cheng P, Wong KW (1995) J Heat Transfer 117:264

Landolt-Börnstein, Zahlenwerte und Funktionen, Band IV Technik, 4. Wärmetechnik a, 6. Auflage, Heidelberg, 1980

Mark JE (1996) Physical properties of polymers handbook. American Institute of Physics, Woodbury, NY

Gane PAC, Kettle JP, Matthews GP, Ridgway CJ (1996) Ind Eng Chem Res 35(5):1753

Guérin D, Morin V, Chaussy D, Auriault JL (2001) Thermal conductivity of handsheets, papers and model coating layers, the science of papermaking, 12th fundamental research symposium, Oxford, Fundamental Research Society, Bury, UK, pp 927–945

Ridgway CJ, Gane PAC (2007) J Pulp Paper Sci 33(2):71

Laudone GM, Matthews GP, Gane PAC (2006) J Colloid Interface Sci 304:180

Acknowledgements

Grateful thanks are given to Omya Development AG for its continuing financial support of this work. A particular thanks also to Dr. Cathy J. Ridgway, Senior Scientist at Omya’s R&D Laboratories, Oftringen, Switzerland, for her expertise and support in assisting in the sample construction and determination of coating pore structure.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gerstner, P., Paltakari, J. & Gane, P.A.C. Measurement and modelling of heat transfer in paper coating structures. J Mater Sci 44, 483–491 (2009). https://doi.org/10.1007/s10853-008-3099-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-008-3099-7