Abstract

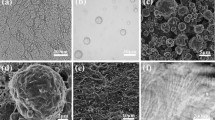

Flexible composite films were produced by impregnating aqueous phenol formaldehyde (PF) resin into water-swollen cellulose nanofibril (CNF) films. CNF films were prepared using a pressurized filtration method in combination with freeze drying. The freeze-dried films were swollen with water then impregnated with PF resin by soaking in aqueous resin solutions of varying concentrations. Small amounts of PF slightly enhanced the tensile properties of CNF films. The formulation with the best mechanical properties was CNF/PF films with 8 wt % resin exhibiting tensile stress and toughness of 248 MPa and 26 MJ/m3, respectively. Resin concentrations higher than about 8 % resulted in composites with decreased tensile properties as compared to neat CNF films. The wet strength of the composite films was significantly higher than that of the neat CNF films. The resulting composites showed greater resistance to moisture absorption accompanied by reduced thickness swelling when soaked in water as compared to neat CNF films. The composites also showed decreased oxygen permeability at low humidity compared to neat films, but the composites did not show improved barrier properties at high humidity.

Similar content being viewed by others

References

Andresen M, Johansson L-S, Tanem BS, Stenius P (2006) Properties and characterization of hydrophobized microfibrillated cellulose. Cellulose 13(6):665–677

ASTM (2010a) Annual Book of ASTM Standards, ASTM D638–10: standard test method for tensile properties of plastics. ASTM International, West Conshohockon

ASTM (2010b) Annual Book of ASTM Standards, ASTM D3985–05e1: standard test method for oxygen gas transmission rate through plastic film and sheeting using a coulometric sensor. ASTM International, West Conshohockon

Aulin C, Ahola S, Joseffson P, Nishino T, Hirose Y, Österberg M, Wågberg L (2009) Nnaoscale cellulose films with different crystallinities and mesostructures-their surface properties and interaction with water. Langmuir 25(13):7675–7685

Aulin C, Gällstedt M, Lindström T (2010) Oxygen and oil barrier properties of microfibrillated cellulose films and coatings. Cellulose 17(3):559–574

Conley RT, Bieron JF (1963) A study of the oxidative degradation of phenol-formaldehyde polycondensates using infrared spectroscopy. J Appl Polym Sci 7(1):103–117

Czaja WK, Young DJ, Kawecki M, Brown RM (2007) The future prospects of microbial cellulose in biomedical applications. Biomacromolecules 8(1):1–12

Fukuzumi H, Saito T, Iwata T, Kumamoto Y, Isogai A (2009) Transparent and high gas barrier films of cellulose nanofibers prepared by TEMPO-mediated oxidation. Biomacromolecules 10(1):162–165

Gong G, Pyo J, Mathew AP, Oksman K (2011) Tensile behavior, morphology and viscoelastic analysis of cellulose nanofiber-reinforced (CNF) polyvinyl acetate (PVAc). Compos Part A 42(9):1275–1282

Henriksson M, Berglund LA (2007) Structure and properties of cellulose nanocomposite films containing melamine formaldehyde. J Appl Polym Sci 106(4):2814–2817

Heriksson M, Berglund LA, Isaksson P, Lindström T, Nishino T (2008) Cellulose nanopaper structure of high toughness. Biomacromolecules 9(6):1579–1585

Iwamoto S, Kai W, Isogai A, Iwata T (2009) Elastic modulus of single cellulose microfibrils from tunicate measured by atomic force microscopy. Biomacromolecules 10(9):2571–2576

Iwatake A, Nogi M, Yano H (2008) Cellulose nanofiber-reinforced polylacitic acid. Compos Sci Technol 68(9):2103–2106

Johnson RK, Zink-Sharp A, Renneckar SH, Glasser WG (2009) A new bio-based nanocomposite: fibrillated TEMPO-oxidized celluloses in hydroxypropylcellulose matrix. Cellulose 16(2):227–238

Lu J, Askeland P, Drzal LT (2008) Surface modification of microfibrillated cellulose for epoxy composite applications. Polymer 49(5):1285–1296

Minelli M, Baschetti MG, Doghieri F, Ankerfors M, Lindström T, Siró I, Plackett D (2010) Investigation of mass transport properties of microfibrillated cellulose (MFC) films. J Membr Sci 358(1–2):67–75

Nakagaito AN, Yano H (2005) Novel high-strength biocomposites based on micro fibrillated cellulose having nano-order-unit web-like network structure. Appl Phys A 80(1):155–159

Nakagaito AN, Yano H (2008) The effect of fiber content on the mechanical and thermal expansion properties of biocomposites based on microfibrillated cellulose. Cellulose 15(4):555–559

Nogi M, Iwamoto S, Nakagaito AN, Yano H (2009) Optically transparent nanofiber paper. Adv Mater 21(16):1595–1598

Nyström G, Mihranyan A, Razaq A, Lindström T, Nyholm L, Strømme M (2010) A nanocellulose polypyrrole composite based on microfibrillated cellulose from wood. J Phys Chem B 114(12):4178–4182

Okahisa Y, Yoshida A, Miyaguchi S, Yano H (2009) Optically transparent wood-cellulose nanocomposite as a base substrate for flexible organic light-emitting diode displays. Compos Sci Technol 69(11–12):1958–1961

Olsson RT, Azizi Samir MAS, Salazar-Alvarez G, Belova L, Ström V, Berglund LA, Ikkala O, Nogués J, Gedde UW (2010) Making flexible magnetic aerogels and stiff magnetic nanopaper using cellulose nanofibrils as templates. Nat Nanotechnol 5(8):584–588

Pääkkö M, Vapaavuori J, Silvennoinen R, Kosonen H, Ankerfors M, Lindström T, Berglund LA, Ikkala O (2008) Long and entangled native cellulose Ι nanofibers allow flexible aerogels and hierarchically porous templates for functionalities. Soft Matter 4(12):2492–2499

Pizzi A, Eaton NJ (1987) A conformational analysis approach to phenol-formaldehyde resins adhesion to wood cellulose. J Adhes Sci Technol 1(1):191–200

Procter HR (1914) The equilibrium of dilute hydrochloric acid and gelatin. J Chem Soc 105:313–327

Qing Y, Sabo R, Wu Y, Cai Z (2012) High-performance cellulose nanofibril composite films. Bio Res 7(3):3064–3075

Rodionova G, Saito T, Lenes M, Eriksen G, Fukuzumi H, Isogai A (2012) Mechanical and oxygen barrier properties of films prepared from fibrillated dispersions of TEMPO-oxidized Norway spruce and Eucalyptus pulps. Cellulose 19(3):705–711

Sabo R, Seo JH, Ma Z (2012) Cellulose nanofiber composite substrates for flexible electronics, 2012 TAPPI International Conference on Nanotechnology for Renewable Materials. Montreal, Quebec

Saito T, Isogai A (2007) Wet strength improvement of TEMPO-oxidized cellulose sheets prepared with cationic polymers. Ind Eng Chem Res 46(3):773–780

Saito T, Hirota M, Tamura N, Kimura S, Fukuzumi H, Heux L, Isogai A (2009) Individualization of nano-sized plant cellulose fibrils by direct surface carboxylation using TEMPO catalyst under neutral conditions. Biomacromecules 10(7):1992–1996

Sasso C, Zeno E, Petit-Conil M, Chaussy D, Belgacem MN, Tapin-Lingua S, Beneventi D (2010) Highly conducting polypyrrole/cellulose nanocomposite films with enhanced mechanical properties. Macromol Mater Eng 295(10):934–941

Sehaqui H, Mushi NE, Morimune S, Salajkova M, Nishino T, Berglund LA (2012) Cellulose nanofiber orientation in nanopaper and nanocomposites by cold drawing. ACS Appl Mater Interfaces 4(2):1043–1049

Shimazaki Y, Miyazaki Y, Takezawa Y, Nogi M, Abe K, Ifuku S, Yano H (2007) Excellent thermal conductivity of transparent cellulose nanofiber/epoxy resin nanocomposites. Biomacromolecules 8(9):2976–2978

Siró I, Plackett D (2010) Microfibrillated cellulose and new nanocomposites materials: a review. Cellulose 17(3):459–494

Svagan AJ, Azizi Samir MAS, Berglund LA (2007) Biomimetic polysaccharide nanocomposites of high cellulose content and high toughness. Biomacromolecules 8(8):2556–2563

Syverud K, Stenius P (2009) Strength and barrier properties of MFC films. Cellulose 16(1):75–85

Tingaut P, Zimmermann T, Lopez-Suevos F (2010) Synthesis and characterization of bionancomposites with tunable properties from poly (lactic acid) and acetylated microfibrillated cellulose. Biomacromolecules 11(2):454–464

Zhu J, Sabo R, Luo X (2011) Integrated production of nano-fibrillated cellulose and biofuel (ethanol) by enzymatic fractionation of wood fibers. Green Chem 13(5):1339–1344

Acknowledgments

Enormous gratitude is offered to Rick Reiner for preparing and supplying TEMPO-oxidized cellulose nanofibrils. The authors would like to acknowledge Benjamin Treml for help with tensile testing. Tom Kuster and Jane O’Dell are kindly acknowledged for SEM and DMTA tests, respectively. The authors would also like to thank Joseph Jakes and Jane O’Dell for performing AFM scans. This work was partly supported by the national “948” project of China (2009-4-51).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Qing, Y., Sabo, R., Cai, Z. et al. Resin impregnation of cellulose nanofibril films facilitated by water swelling. Cellulose 20, 303–313 (2013). https://doi.org/10.1007/s10570-012-9815-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-012-9815-0