Abstract

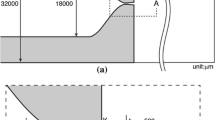

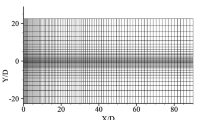

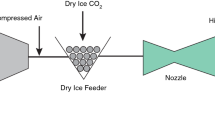

In this paper, both DSMC and Navier–Stokes computational approaches were applied to study micronozzle flow. The effects of inlet condition, wall boundary condition, Reynolds number, micronozzle geometry and Knudsen number on the micronozzle flow field and propulsion performance were studied in detail. It is found that within the Knudsen number range under consideration, both the methods work to predict flow characteristics inside micronozzles. The continuum method with slip boundary conditions has shown good performance in simulating the formation of a boundary layer inside the nozzle. However, in the nozzle exit lip region, the DSMC method is better due to gas rapid expansion. It is found that with decreasing the inlet pressure, the difference between the continuum model and DSMC results increases due to the enhanced rarefaction effect. The coefficient of discharge and the thrust efficiency increase with increasing the Reynolds number. Thrust is almost proportional to the nozzle width. With dimension enlarged, the nozzle performance becomes better while the rarefaction effects would be somewhat weakened.

Similar content being viewed by others

References

Rossi C. (2002). Micropropulsion for space – a survey of mems-based micro thrusters and their solid propellant technology. Sensors Updates 10:257–292

Lewis D., Janson S., Become R., Antonsson E. (2000). digital micropropulsion. Sensors Actuat. A Phys. 80:143–154

Ketsdever A.D., Clarbough M., Gimelshein S.F., Alexeenko A.A. (2005). Experimental and numerical determination of micropropulsion device efficiencies at low Reynolds numbers. J. AIAA 43(3):633–641

Bayt R.L. (1999). Analysis, fabrication and testing of a MEMS- fabricated micronozzles. PhD Thesis. MIT, Cambridge

Choudhuri, A.R., Barid, B., Gollahalli, S.R.: Effects geometry and ambient pressure on micronozzle flow. AIAA paper 2001–3331, Salt Lake City, Utah (2001)

Reed, B.: Decomposing solid micropropulsion nozzle performance issues. AIAA paper 2003-0672, Reno, Nevada (2003)

Gad-el-Hak M. (1999). The fluid mechanics of microdevices – the freeman scholar lecture. J. Fluids Eng. 121:5–33

Alexeenko, A., Collins, R.J., Gimelshein, S.F., Levin, D.A.: Challenges of three-dimensional modeling of microscale propulsion devices with the DSMC method. In: Proceedings of 22nd symposium on rarefied gas dynamics, Sydney, Australia (2000)

Piekos E.S., Breuer K.S. (1996). Numerical modeling of micro-mechanical devices using the direct simulation Monte Carlo method. J. Fluids Eng. 118:464–469

Markelov G.N., Ivanov M.S. (2001). Numerical study of 2D/3D micronozzle flows. AIP Conf. Proc. 585(1):539–546

Wang M.R., Li Z.X. (2004). Numerical simulations on performance of MEMS-based nozzles at moderate or low temperatures. Microfluidics Nanofluidics 1:62–70

Bird G.A. (1994). Molecular Gas Dynamics and the Direct Simulation of Gas Flows. Clarendon Press, Oxford

Shen C. (2005). Rarefied Gas Dynamics. Fundamentals, Simulation and Micro Flows. Springer, Berlin Heidelberg New York

Ikegawa M., Kobayashi J. (1990). Development of a rarefied flow simulator using the DSMC method. JSME Int. J. 30:463–467

Nance R.P., Hash D.B., Hassan H.A. (1998). Role of boundary conditions in Monte Carlo simulation of MEMS devices. J. Thermalphys. Heat Transfer 12:447–449

Liou W.W., Fang Y. (2000). Implicit boundary conditions for direct simulation Monte Carlo method in MEMS flow predictions. Comput. Model. Eng. Sci. 4:119–128

Zhang G.X., Cai X.D., Liu M.H., Chen Y.L. (2004). Cold flow field and propulsive performance of a micro laval nozzle (in Chinese). J. Propulsion Technol. 25:54–57

Bayt, R.L., Breuer, K.S.: Viscous effects in supersonic mems-fabricated micronozzles. In: Proceedings of the 1998 ASME International Mechanical Engineering Congress and Exposition, Anaheim (1998)

Author information

Authors and Affiliations

Corresponding author

Additional information

The project supported by the National Natural Science Foundation of China (10372099). The English text was polished by Boyi Wang

Rights and permissions

About this article

Cite this article

Liu, M., Zhang, X., Zhang, G. et al. Study on micronozzle flow and propulsion performance using DSMC and continuum methods. Acta Mech Mech Sinica 22, 409–416 (2006). https://doi.org/10.1007/s10409-006-0020-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10409-006-0020-y