Abstract

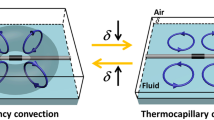

This work demonstrates an optofluidic system, where dielectrophoretically controlled suspended nanoparticles are used to manipulate the properties of an optical waveguide. This optofluidic device is composed of a multimode polymeric rib waveguide and a microfluidic channel as its upper cladding. This channel integrates dielectrophoretic (DEP) microelectrodes and is infiltrated with suspended silica and tungsten trioxide nanoparticles. By applying electrical signals with various intensities and frequencies to the DEP microelectrodes, the nanoparticles can be concentrated close to the waveguide surface significantly altering the optical properties in this region. Depending on the particle refractive indices, concentrations, positions and dimensions, the light remains confined or is scattered into the surrounding media in the microfluidic channel.

Similar content being viewed by others

References

Ahn K, Kerbage C, Hunt TP, Westervelt RM, Link DR, Weitz DA (2006) Dielectrophoretic manipulation of drops for high-speed microfluidic sorting devices. Appl Phys Lett 88(2):024104

Airoudj A, Bêche B, Debarnot D, Gaviot E, Poncin-Epaillard F (2009) Integrated SU-8 photonic gas sensors based on PANI polymer devices: comparison between metrological parameters. Opt Commun 282(19):3839–3845

Applegate RW, Squier J, Vestad T, Oakey J, Marr D, Bado P, Dugan M, Said A (2006) Microfluidic sorting system based on optical waveguide integration and diode laser bar trapping. Lab Chip 6(3):422–426

Ateya DA, Erickson JS, Howell PB, Hilliard LR, Golden JP, Ligler F (2008) The good, the bad and the tiny: a review of microflow cytometry. Anal Bioanal Chem 391(5):1485–1498

Bernini R, De Nuccio E, Minardo A, Zeni L, Sarro P (2008) Liquid-core/liquid-cladding integrated silicon ARROW waveguides. Opt Commun 281(8):2062–2066

Calixto S, Rosete-Aguilar M, Sanchez-Marin FJ, Maranon V, Arauz-Lara JL, Olivares DM, Calixto-Solano M, Martinez-Prado EM (2010) Optofluidic compound microlenses made by emulsion techniques. Opt Express 18(18):18703–18711

Callister WD, Rethwisch DG (2010) Materials science and engineering: an introduction, 8th edn. John Wiley, Hoboken, NJ

Chen C-L (2007) Foundations for guided-wave optics. Wiley, Hoboken

Chrimes AF, Kayani AA, Khoshmanesh K, Stoddart PR, Mulvaney P, Mitchell A, Kalantar-zadeh K (2011) Dielectrophoresis-Raman spectroscopy system for analysing suspended nanoparticles. Lab Chip. doi:10.1039/c0lc00481b

Compopiano S, Bernini R, Zeni L, Sarro P (2004) Microfluidic sensor based on integrated optical hollow waveguides. Opt Lett 29(16):1894–1896

Cui L, Holmes D, Morgan H (2001) The dielectrophoretic levitation and separation of latex beads in microchips. Electrophoresis 22(18):3893–3901

Datta A, Eom I-Y, Dhar A, Kuban P, Manor R, Ahmad I, Gangopadhyay S, Dallas T, Holtz M, Temkin H, Dasgupta PK (2003) Microfabrication and characterization of teflon AF-coated liquid core waveguide channels in silicon. IEEE Sens J 3(6):788–795

Domachuk P, Cronin-Golomb M, Eggleton BJ (2006) Application of optical trapping to beam manipulation in optofluidics. Opt Express 13(19):7265–7275

Dress P, Franke H (1996) A cylindrical liquid-core waveguide. Appl Phys B 63(1):12–19

Durr M, Kentsch J, Muller T, Schnelle T, Stelzle M (2003) Microdevices for manipulation and accumulation of micro- and nanoparticles by dielectrophoresis. Electrophoresis 24(4):722–731

Erickson D, Mandal S, Yang AHJ, Cordovez B (2008) Nanobiosensors: optofluidic, electrical and mechanical approaches to biomolecular detection at the nanoscale. Microfluid Nanofluid 4(1–2):33–52

Gaiduk VI, Crothers DSF (2006) Basic molecular mechanisms underlying complex permittivity of water and ice. J Phys Chem A 110(30):9361–9369

Gillet M, Aguir K, Lemire C, Gillet E, Schierbaum K (2004) The structure and electrical conductivity of vacuum-annealed WO3 thin films. Thin Solid Films 467(1–2):239–246

Groisman A, Zamek S, Campbell K, Pang L, Levy U, Fainman Y (2008) Optofluidic 1 × 4 switch. Opt Express 16(18):13499–13508

Haeberle S, Zengerle R (2007) Microfluidic platforms for lab-on-a-chip applications. Lab Chip 7(9):1094–1110

Hitz B (2006) Thermal gradient in microfluidic channel creates a waveguide: technique offers potential path to readily reconfigurable optical components. Photon Spectra 40(5):26–28

Jiang L, Pau S (2007) Integrated waveguide with a microfluidic channel in spiral geometry for spectroscopic applications. Appl Phys Lett 90(11):111108

Jiang L, Gerhardt KP, Myer B, Zohar Y, Pau S (2008) Evanescent-wave spectroscopy using an SU-8 waveguide for rapid quantitative detection of biomolecules. J Microelectromech Syst 17(6):1495–1500

Jiang H, Weng X, Li D (2010) Microfluidic whole-blood immunoassays. Microfluid Nanofluid 1–24. doi:10.1007/s10404-010-0718-9

Jonas A, Zemanek P (2008) Light at work: the use of optical forces for particle manipulation, sorting, and analysis. Electrophoresis 29(24):4813–4851

Kalantar-zadeh K, Khoshmanesh K, Kayani AA, Nahavandi S, Mitchell A (2010) Dielectrophoretically tuneable optical waveguides using nanoparticles in microfluidics. Appl Phys Lett 96(10):101108

Kayani AA, Zhang C, Khoshmanesh K, Campbell JL, Mitchell A, Kalantar-zadeh K (2010) Novel tuneable optical elements based on nanoparticle suspensions in microfluidics. Electrophoresis 31(6):1071–1079

Khoshmanesh K, Zhang C, Tovar-Lopez FJ, Nahavandi S, Baratchi S, Kalantar-zadeh K, Mitchell A (2009) Dielectrophoretic manipulation and separation of microparticles using curved microelectrodes. Electrophoresis 30(21):3707–3717

Khoshmanesh K, Zhang C, Campbell JL, Kayani AA, Nahavandi S, Mitchell A, Kalantar-zadeh K (2010a) Dielectrophoretically assembled particles: feasibility for optofluidic systems. Microfluid Nanofluid 9(4–5):755–763

Khoshmanesh K, Zhang C, Tovar-Lopez FJ, Nahavandi S, Baratchi S, Mitchell A, Kalantar-zadeh K (2010b) Dielectrophoretic-activated cell sorter based on curved microelectrodes. Microfluid Nanofluid 9(2–3):411–426

Kim JS, Kang JW, Kim JJ (2003) Simple and low cost fabrication of thermally stable polymeric multimode waveguides using a UV-curable epoxy. Jpn J Appl Phys 1 42(3):1277–1279

Kostovski G, White DJ, Mitchell A, Austin MW, Stoddart PR (2009) Nanoimprinted optical fibres: biotemplated nanostructures for SERS sensing. Biosens Bioelectron 24(5):1531–1535

Kuhn S, Measor P, Lunt EJ, Phillips BS, Deamer DW, Hawkins AR, Schmidt H (2009) Loss-based optical trap for on-chip particle analysis. Lab Chip 9(15):2212–2216

Lee KS, Lee H, L.T., Ram RJ et al (2007) Polymer waveguide backplanes for optical sensor interfaces in microfluidics. Lab Chip 7(11):1539–1545

Li H, Fan XD (2010) Characterization of sensing capability of optofluidic ring resonator biosensors. Appl Phys Lett 97(1):011105

Li XC, Wu J, Liu AQ, Li ZG, Soew YC, Huang HJ, Xu K, Lin JT (2008) A liquid waveguide based evanescent wave sensor integrated onto a microfluidic chip. Appl Phys Lett 93(19):193901

Lien V, Berdichevsky Y, Lo Y-H (2004) A prealigned process of integrating optical waveguides with microfluidic devices. IEEE Photon Technol Lett 16(6):1525–1527

Liu GL, Kim J, Lee LP (2006) All-optical microfluidic circuit for biochemical and cellular analysis powered by photoactive nanoparticles. In: Psaltis D, Fainman Y (eds) Proceedings of The society of photo-optical instrumentation engineers (SPIE), San Diego, CA, 2006. SPIE- International Society of Optical Engineering, pp 121–128

Mach P, Dolinski M, Baldwin KW, Rogers JA, Kerbage C, Windeler RS, Eggleton BJ (2002) Tunable microfluidic optical fiber. Appl Phys Lett 80(23):4294–4296

Mark D, Haeberle S, Roth G, von Stetten F, Zengerle R (2010) Microfluidic lab-on-a-chip platforms: requirements, characteristics and applications. Chem Soc Rev 39(3):1153–1182

McDonald JC, Duffy DC, Anderson JR, Chiu DT, Wu HK, Schueller OJA, Whitesides GM (2000) Fabrication of microfluidic systems in poly(dimethylsiloxane). Electrophoresis 21(1):27–40

Mogensen KB, El-Ali J, Wolff A, Kutter JP (2003) Integration of polymer waveguides for optical detection in microfabricated chemical analysis systems. Appl Opt 42(19):4072–4079

Nguyen NT (2010) Micro-optofluidic lenses: a review. Biomicrofluidics 4(3):031501–031516

Nguyen NT, Kong TF, Goh JH, Low CLN (2007) A micro optofluidic splitter and switch based on hydrodynamic spreading. J Micromech Microeng 17(11):2169–2174

Okamoto K (2006) Fundamentals of optical waveguides, 2nd edn. Elsevier, Boston

Pohl H (1978) Dielectrophoresis, the behavior of neutral matter in nonuniform electric fields, 1st edn. Cambridge University Press, New York

Polynkin P, Polynkin A, Peyghambarian N, Mansuripur M (2005) Evanescent field-based optical fiber sensing device for measuring the refractive index of liquids in microfluidic channels. Optics Letters 30(11):1273–1275

Qin D, Xia YN, Rogers JA, Jackman RJ, Zhao XM, Whitesides GM (1998) Microfabrication, microstructures and microsystems. Microsyst Technol Chem Life Sci 194:1–20

Risk WP, Kim HC, Miller RD (2004) Optical waveguides with an aqueous core and a low index nanoporous cladding. Opt Express 12(26):6446–6455

Schmid JH, Delage A, Lamontagne B, Lapointe J, Janz S, Cheben P, Densmore A, Waldron P, Xu DX, Yap KP (2008) Interference effect in scattering loss of high-index-contrast planar waveguides caused by boundary reflections. Optics Letters 33(13):1479–1481

Schmidt H, Hawkins AR (2008) Optofluidic waveguides: I. Concepts and implementations. Microfluid Nanofluid 4(1-2):3–16

Schueller OJA, Zhao XM, Whitesides GM, Smith SP, Prentiss M (1999) Fabrication of liquid-core waveguides by soft lithography. Adv Mater 11(1):37–41

Seow YC, Lim SP, Lee HP (2009) Tunable optofluidic switch via hydrodynamic control of laminar flow rate. Appl Phys Lett 95(11):114105

Seow YC, Lim SP, Khoo BC, Lee HP (2010) An optofluidic refractive index sensor based on partial refraction. Sens Actuators B 147(2):607–611

Sheridan AK, Stewart G, Ur-Reyman H, Suyal N, Uttamchandani D (2009) In-plane integration of polymer microfluidic channels with optical waveguides—a preliminary investigation. IEEE Sens J 9(12):1627–1632

Tang S, Stan C, Whitesides GM (2008) Dynamically reconfigurable liquid-core liquid-cladding lends in a microfluidic channel. Lab Chip 8(3):395–401

Vestad T, Brown M, Oakey J, Marr DWM (2005) Reconfigurable microfluidic waveguides for onchip flow cytometry. Micro Total Anal Syst 1(296):653–655

Vishnubhatla KC, Clark J, Lanzani G, Ramponi R, Osellame R, Virgili T (2009) Ultrafast optofluidic gain switch based on conjugated polymer in femtosecond laser fabricated microchannels. Appl Phys Lett 94(4):041123

White CM, Holland LA, Famouri P (2010) Application of capillary electrophoresis to predict crossover frequency of polystyrene particles in dielectrophoresis. Electrophoresis 31(15):2664–2671

Whitesides GM (2006) The origins and the future of microfluidics. Nature 442:368–373

Wolfe DB, Conroy RS, Garstecki P, Mayers BT, Fischbach M, Paul K, Prentiss M, Whitesides GM (2004) Dynamic control of liquid-core/liquid-cladding optical waveguides. PNAS 101(34):12434–12438

Xia YN, Whitesides GM (1998) Soft lithography. Annu Rev Mat Sci 28:153–184

Yan RJ, Yuan GW, Stephens MD, He XY, Henry CS, Dandy DS, Lear KL (2008) Evanescent field response to immunoassay layer thickness on planar waveguides. Appl Phys Lett 93(10):101110

Yin DL, Lunt EJ, Rudenko MI, Deamer DW, Hawkins AR, Schmidt H (2007) Planar optofluidic chip for single particle detection, manipulation, and analysis. Lab Chip 7(9):1171–1175

Zhang C, Khoshmanesh K, Tovar-Lopez FJ, Mitchell A, Wlodarski W, Klantar-zadeh K (2009) Dielectrophoretic separation of carbon nanotubes and polystyrene microparticles. Microfluid Nanofluid 7(5):633–645

Zhang C, Khoshmanesh K, Mitchell A, Kalantar-zadeh K (2010) Dielectrophoresis for manipulation of micro/nano particles in microfluidic systems. Anal Bioanal Chem 396(1):401–420

Author information

Authors and Affiliations

Corresponding authors

Appendices

Appendix 1

Samples of the particle suspensions were placed on glass slides and dehydrated. The samples were then viewed using an FEI Nova SEM (Fig. 8a, b). The SEM images help to provide confirmation of the particles shape and dimensions.

Appendix 2

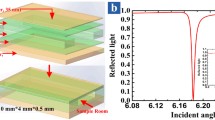

SU-8 epoxy was chosen as the waveguide core material due to its relatively high refractive index and low loss over a wide visible wavelength range (Jiang et al. 2008). The waveguide was fabricated using SU-8 2002 (MicroChem) as the core and KMPR 1035 (MicroChem) as the lower cladding using nanoimprint lithography techniques (Kostovski et al. 2009).

First a layer of KMPR 1035 was spin coated at 3000 r/min for 30 s to form a film of thickness of 35 μm (Fig. 9a). The layer was then soft baked at 100°C for 14 min on a horizontally levelled hotplate. The KMPR layer was then exposed to UV light (Karl Suss MA6) with an exposure dose of 700 mJ/cm2 and cross-linked during the successive post-exposure bake (PEB) for 3 min at 100°C (Fig. 9b). Following this, a 50-nm adhesion layer of chromium (Cr) followed by a 150-nm conductive film of gold (Au) was deposited by electron beam evaporation.

The DEP microelectrodes were then patterned from the gold film (Fig. 9c). This was achieved by spin coating AZ1512 (Microchemicals) with a rotational speed of 3000 r/min followed by soft baking at 90°C for 20 min (Fig. 9d). The photoresist was then exposed with a chrome mask containing patterns of the curved DEP electrodes (Fig. 9e). The photoresist was developed in AZ 1:4 developer for 20 s. The metal layers of Au and Cr were etched using wet chemical etching processes. Au was etched using Aqua Regia (HNO3 + 3HCl) and Cr with Cr etchant (CH3COOH + Ce(NH4) 2(NO3)6 + H2O) for 15 and 110 s, respectively. The photoresist was then removed using acetone, IPA, and DI water (Fig. 9f).

The core waveguide layer was fabricated by spin coating the SU-8 2002 photoresist at 3000 r/min to form a 2-μm film. This was deposited over the patterned microelectrodes (Fig. 9g). The waveguide cast master was fabricated using a diluted version of SU-8 photoresist spun to a thickness of 350 nm and patterned using a 5-μm width waveguide chrome mask. This master was then coated with a thick layer of polydimethylsiloxane (PDMS) enclosed in a shim and was cured to form a nano-imprint lithography stamp (Kostovski et al. 2009). This PDMS stamp was used to imprint the raised rib waveguides onto the sample forming a raised rib replica of the waveguide master. The imprinted sample was then soft baked whilst in contact with the PDMS stamp for 20 min at 65°C, avoiding higher temperatures to prevent thermal distortion of the PDMS stamp. The imprinted SU-8 was then exposed using ultra-violet (UV) light with a dose of 350 mJ/cm2 (Fig. 9h). Post-exposure, the PDMS stamp was removed and the imprinted waveguide was cured by baking at 65°C for 1 min followed by 90°C for 10 min. The sample was then diced using a dicing machine (DAD420) to obtain optically smooth edges (Fig. 9i). The platform including optical waveguides and DEP electrodes was then integrated a 500 μm × 12 mm × 100 μm (w × l × h) microfluidic channel patterned in polydimethylsiloxane (PDMS) which was fabricated using soft lithography techniques (McDonald et al. 2000).

A cast master for the microfluidic channel was then made using SU-8 2050 (Microchem) and spun at 1500 r/min for 30 s to obtain a 100-μm feature height. The master was then soft baked on a hotplate at 65°C for 3 min followed by 95°C for 10 min. Next the wafer master was exposed to UV with a dose of 200 mJ/cm2 using a film mask and post-exposure baked at 65°C for 2 min followed by 95°C for 7 min. A 1:10 mixture of PDMS curing agent:elastomer (Sylgard 184) was mixed, degassed, and poured into microfluidic shims and cured at 75°C for 2 h in an oven. Prior to attachment to the microscope slide, the microfluidic reservoirs were punched with 0.75-mm holes and the channel surface was plasma treated for 2 min to enhance adhesion.

Rights and permissions

About this article

Cite this article

Kayani, A.A., Chrimes, A.F., Khoshmanesh, K. et al. Interaction of guided light in rib polymer waveguides with dielectrophoretically controlled nanoparticles. Microfluid Nanofluid 11, 93–104 (2011). https://doi.org/10.1007/s10404-011-0777-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10404-011-0777-6