Abstract

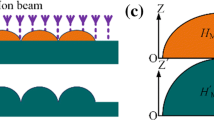

A graduated microlens array is presented in this paper. The proposed device has the same aperture microlens with a gradually increasing sag in the substrate. The design produces gradual decrease in the focal length and intensity when the light passes through the graduated microlens array. This paper presents a new graduated microlens array fabrication method that uses a variable printing gap in the UV lithography process. This method can precisely control the geometric profile of each microlens array without using the thermal reflow process. The angles between the mask and photoresist were placed at 5°, 8°, 10°, 15°, and 20° using a fixture designed in this study. The mask patterns were ellipses with an isosceles triangle arrangement to compensate for the partial geometry.

Similar content being viewed by others

References

Courtesy of Japanese Synthetic Rubber Company

Cox WR, Chen T, Hayes D (2001) Micro-optics fabrication by ink-jet printing. Opt Photonics News 12(6):32–35

Dentinger PM et al (2002) High aspect ratio patterning with a proximity ultraviolet source. Microelectron Eng 61:1001–1007

Ezell B (2001) Making microlens backlights grow up. Inf Disp 5:42–45

Gale MT, Rossi M, Pedersen J, Schutz H (1994) Fabrication of continuous-relief micro-optical elements by direct laser writing in photoresists. Opt Eng 22(11):3556–3566

Gottert J, Mohr J (1991) Characterization of micro-optical components fabricated by deep-etch x-ray lithography. SPIE: Micro-Optics II 1506:170–178

Henke W, Schwalm R, Weiss M, Pelka J (1990) Diffraction effects in submicron contact or proximity printing. Microelectron Eng 10:73–89

Hutley MC (1990) Optical techniques for the generation of microlens arrays. J Mod Opt 37:253–265

Lee S-K, Lee K-C, Lee SS (2002) A simple method for microlens fabrication by the modified LIGA process. J Micromech Microeng 12:334–340

Lin C-P, Yang H, Chao C-K (2003) A new microlens array fabrication method using UV proximity printing. J Micromech Microeng 13:748–757

Matamedi ME, Griswold MP, Knowlden RE (1991) Silicon microlenses for enhanced optical coupling to silicon focal planes. Proc SPIE 1544:22–32

Moller S, Forrest SR (2002) Improved light out-coming in organic light emitting diodes employing ordered microlens arrays. J Appl Phys 91(5):3324–3327

Motamedi ME (1994) Micro-opto-electro-mechanical system. Opt Eng 33(11):3505–3517

Plummer JD (2000) Silicon VLSI technology. Prentice Hall, pp 208–234

Schilling A, Merz R, Ossmann C, Herzig HP (2000) Surface profiles of reflow microlenses under the influence of surface tension and gravity. Opt Eng 39(8):2171–2176

Sinzinger S, Jahns J (1999) Microoptics. Wiley-VCH Verlag GmbH, Weinheim, pp 85–103

Tanaka A (2003) Fujitsu Kasei technology yield thin displays, 2-way brightness, Display Devices vol. Fall: 27–31

Yang H, Pan C-T, Chou M-C (2001) Ultra-fine machining tool/molds by LIGA technology. J Micromech Microeng 11:94–99

Zimmer K, Hirsch D, Bigl F (1996) Excimer laser machining for the fabrication of analogous microstructures. Appl Surface Sci 96–98:425–429

Acknowledgments

This work was supported by the National Science Council (series no. NSC92-2212-E-005-005) of Taiwan, R.O.C. Thanks are due to G. Marso Electronics Inc. (GME) for their cell phone panel module knowledge input to generate research interests.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yang, H., Chao, CK., Lin, TH. et al. Fabrication of microlens array with graduated sags using UV proximity printing method. Microsyst Technol 12, 82–90 (2005). https://doi.org/10.1007/s00542-005-0025-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-005-0025-7