Abstract

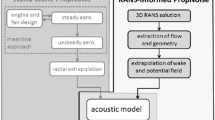

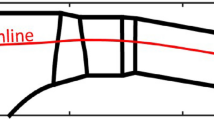

The aero-mechanical optimisation of a fan outlet guide vane (OGV) in the bypass duct of a modern turbofan engine is presented. The purpose of the described outlet guide vane arrangement is to remove the swirl from the flow coming from the fan and to connect the engine core structurally with the bypass duct and the engine mounts respectively. For that reason the outlet guide vanes have to fulfill aerodynamic requirements—such as low pressure loss and large working range and turning of the absolute flow to 0 degree—as well as the structural requirement to withstand the engine loads in all operating conditions. Such an arrangement has the advantage, that additional struts downstream of the fan outlet guide vane become obsolete, which is beneficial for the engine length and weight and hence the engine specific fuel consumption. At the same time the structural and aerodynamic requirements on such an outlet guide vane are intuitively contradictory. Therefore the design is more complex than for a conventional purely aerodynamic guide vane. To achieve the different requirements the conventional iterative design process has been replaced by a multi-disciplinary approach, which delivers an aero-mechanically optimised fan outlet guide vane geometry based on aerodynamic and mechanical boundary conditions and constraints. The prescribed boundary conditions are the structural load cases (flight conditions) and the aerodynamic inlet and outlet conditions for the fan design point. In addition an existing bypass duct geometry is used to get a valid comparison with a conventionally designed outlet guide vane/strut arrangement. In the structural optimisation, carried out as a parameter study, the effect of several geometrical parameters is investigated using the software ABAQUS. The aerodynamic optimisation is performed using the 2D-CFD-solver MISES on individual profile sections such that a minimum pressure loss and a maximum working range is achieved. For that purpose the profile shape is modified freely taking into account the constraints from the structural optimisation. A 3D-RANS-CFD analysis of the optimised vane and the comparison with the conventional vane/strut arrangement confirmed the improved performance of the chosen design approach and showed a significant reduction in pressure loss (ΔP/D) of nearly 20% compared to the conventional OGV/strut arrangement, leading to an SFC reduction of about 0.5%.

Similar content being viewed by others

Abbreviations

- \(\upbeta _{2}\) :

-

Outlet angle

- CFD:

-

Computational fluid dynamics

- D:

-

Dynamic pressure

- DoE:

-

Design of experiment

- Δ:

-

Difference

- ff:

-

Fitness function

- mm:

-

Millimeter

- MTO:

-

Maximum take-off

- MRT:

-

Maximum reverse thrust

- N:

-

Newton

- P:

-

Total pressure

- RANS:

-

Reynolds-Averaged-Navier-Stokes

- (S)OGV:

-

(Structural) outlet guide vane

- SFC:

-

Specific fuel consumption

- WEM:

-

Whole engine model

- \(\upomega\) :

-

Loss

- 2D/3D:

-

Two/three-dimensional

References

Clemen C, Stark U (2003) Compressor blades with sweep and dihedral: a parameter study. In: 5th European conference on turbomachinery/Prague, Czech Republic

Drela M, Youngren H (1996) A users’s guide to MISES 2.4. MIT Computational Aerospace Sciences Laboratory

Falkenauer E (1994) Genetic algorithms and grouping problems. Wiley, Chichester

Goldberg DE (1989) Genetic algorithms in search optimization and machine learning. Addison Wesley

Gustavsson R (2006) Design study of advanced metallic structural integrated fan outlet guide vanes in civil jet engines. Master’s Thesis, Lulea University of Technology, Department of Applied Physics and Mechanical Engineering, Division of CAD, Lulea, Sweden

Holewa A, Kröger G, Nicke E, Clemen C, Herzog H (2009) Optimisation of the struts in a bypass duct of a civil aircraft engine to minimize the circumferential pressure variation. ISABE-2009-1152

Hughes CE (2001) Aerodynamic performance of scale-model turbofan outlet guide vanes designed for low noise. NASA/TM-2001-211352, AIAA-2202-0374

Lapworth L (2004) HYDRA-CFD: a framework for collaborative cfd development”. In: International conference on scientific and engineering computation (IC-SEC), Singapore, 30 June–02 July 2004

Oessenich R (2004) Kosten- und gewichtsoptimierte Designkonzeptstudie eines Intermediate Compressor Gehäuses (IMC) für eine zukünftige Zweiwellen-Triebwerksandwendung. Diploma-thesis at Rolls-Royce Deutschland Ltd. & Co. KG, Dahlewitz, Germany

Shahpar S, Lapworth L (2003) PADRAM: parametric design and rapid meshing system for turbomachinery optimisation. In: Paper GT-2003-38698, ASME turbo expo, Atlanta Georgia, 16–19 June 2003

Spalart PR, Allmaras SR (1992) A one-equation turbulence model for aerodynamic flows. AIAA Paper 92-0439

Voss C, Nicke E (2008) Automatische Optimierung von Verdichterstufen. Technical Library Hannover, University Hannover, Germany

Walker AD, Carotte JF, McGuirk JJ (2006) Enhanced external aerodynamic performance of a generic combustor using an integrated ogv/prediffuser design technique. In: ASME Turbo Expo 2006, Barcelona, Spain, GT2006-90184, vol 129, pp 80–93

Acknowledgements

The author would like to thank the government of Brandenburg for funding the presented work in the frame of the research project OPAL and the management of Rolls-Royce Deutschland Ltd. & Co. KG for the permission to publish this work. Thanks to Axel Holewa (DLR) and Dr. Thomas Klauke for their contribution to this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Clemen, C. Aero-mechanical optimisation of a structural fan outlet guide vane. Struct Multidisc Optim 44, 125–136 (2011). https://doi.org/10.1007/s00158-010-0617-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00158-010-0617-4