Abstract

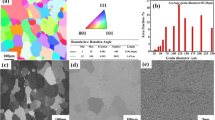

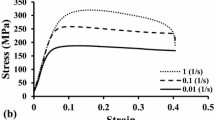

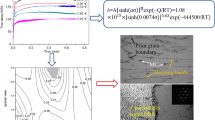

The hot-working characteristics of IN-718 are studied in the temperature range 900 °C to 1200 °C and strain rate range 0.001 to 100 s−1 using hot compression tests. Processing maps for hot working are developed on the basis of the strain-rate sensitivity variations with temperature and strain rate and interpreted using a dynamic materials model. The map exhibits two domains of dynamic recrystallization (DRX): one occurring at 950 °C and 0.001 s−1 with an efficiency of power dissipation of 37 pct and the other at 1200 °C and 0.1 s−1 with an efficiency of 40 pct. Dynamic recrystallization in the former domain is nucleated by the δ(Ni3Nb) precipitates and results in fine-grained microstructure. In the high-temperature DRX domain, carbides dissolve in the matrix and make interstitial carbon atoms available for increasing the rate of dislocation generation for DRX nucleation. It is recommended that IN-718 may be hot-forged initially at 1200 °C and 0.1 s−1 and finish-forged at 950 °C and 0.001 s−1 so that fine-grained structure may be achieved. The available forging practice validates these results from processing maps. At temperatures lower than 1000 °C and strain rates higher than 1 s−1 the material exhibits adiabatic shear bands. Also, at temperatures higher than 1150°C and strain rates more than 1s−1, IN-718 exhibits intercrystalline cracking. Both these regimes may be avoided in hotworking IN-718.

Similar content being viewed by others

References

Metallurgy and Applications of Superalloy 718, Edward A. Loria, ed., TMS-AIME, Warrendale, PA, 1989.

A.E. Marsh:Metallurgia, 1982, vol. 49, pp. 10–20.

R.E. Bailey: Report No. SP-69-9, Allegheny Ludlum Steel Research Center, Brackenridge, PA, 1969.

P.K. Chaudhury, J.J. Valencia, and D. Zhao:Materials Week ’92, ASM and TMS, Chicago, IL, p. 65 (Abstract).

Y.V.R.K. Prasad, H.L. Gegel, S.M. Doraivelu, J.C. Malas, J.T. Morgan, K.A. Lark, and D.R. Barker:Metall. Trans. A, 1984, vol. 15A, pp. 1883–92.

H.L. Gegel, J.C. Malas, S.M. Doraivelu, and V.A. Shende:Metals Handbook, ASM, Metals Park, OH, 1987, vol. 14, pp. 417–38.

J.M. AlexanderModelling of Hot Deformation of Steels, Springer-Verlag, Berlin, 1989, pp. 101–14.

H. Ziegler:Progress in Solid Mechanics, John Wiley and Sons, New York, NY, 1963, vol. 4, pp. 93–193.

A.K.S. Kalyan Kumar: Master’s Thesis, Indian Institute of Science, Bangalore, 1987.

Y.V.R.K. Prasad:Ind. J. Technol., 1990, vol. 28, pp. 435–51.

C.T. Sims and W.C. Hagel:The Superalloy, Wiley-Interscience Publishing, New York, NY, 1972.

R. Raj:Metall. Trans. A, 1981, vol. 12A, pp. 1089–97.

N. Srinivasan and Y.V.R.K. Prasad:Mater. Sci. Technol., 1992, vol. 8, pp. 206–12.

N. Srinivasan and Y.V.R.K. Prasad:J. Mater. Process. Technol., 1994, vol. 41, pp. 409–24.

M.J. Luton and CM. Seilars:Acta Metall., 1969, vol. 17, pp. 1033–43.

H.J. McQueen and J.J. Jonas:Treatise Mater. Sci. Technol., 1975, vol. 6, pp. 393–493.

T.E. Howson and W.J. Couts, Jr.:Metallurgy and Applications-Superalloy 718, TMS-AIME, Warrandale, PA, 1989, pp. 685–94.

P.E. Mosser, G. Leconte, J. Leray, A. Lasalmonie, and Y. Honnarat:Metallurgy and Applications-Superalloy 718, TMS-AIME, Warrandale, PA, 1989, pp. 79–93.

N. Srinivasan and Y.V.R.K. Prasad:Mater. Sci. Technol., in press.

M. Ueki, S. Horie, and T. Nakamura:Mater. Sci. Technol., 1987, vol. 3, pp. 329–37.

M.N. Shetty and A.K. Laha:Z. Metallkd., 1986, vol. 6, pp. 397–402.

N. Srinivasan and Y.V.R.K. Prasad: Indian Institute of Science, Bangalore, unpublished research, 1993.

B.E.P. Beeston and L.K. France:J. Inst. Met., 1968, vol. 96, pp. 105–07.

K. Monma; H. Suto, and H. Oikama:J. Jpn. Inst. Met., 1964, vol. 28, pp. 188–96.

D.D. Pruthi, M.S. Anand, and R.P. Agarwala:J. Nucl. Mater., 1977, vol. 64, pp. 206–10.

W.J. McG. Tegart:Ductility, ASM, Metals Park, OH, 1968, pp. 133–77.

W.A. Wilkinson:Metallurgy and Applications—Superalloy 718, TMS-AIME, Warrandale, PA, 1989, pp. 119–34.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Srinivasan, N., Prasad, Y.V.R.K. Microstructural control in hot working of IN-718 superalloy using processing map. Metall Mater Trans A 25, 2275–2284 (1994). https://doi.org/10.1007/BF02652327

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02652327