Abstract

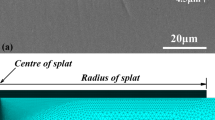

A combined theoretical and experimental study is reported which investigates remelting phenomena during the splat cooling of two liquid-metal droplets impacting sequentially on a substrate. Under conditions of sufficiently high superheat it was proposed theoretically and demonstrated experimentally that an initial deposit is remelted by the subsequent impact of molten material. It is shown that the amount of superheat as well as the variation of thermophysical properties, particularly the latent heat and the melting temperature, influence the degree of remelting. Experimental findings supported to a certain extent the theoretical model assumptions that the splats could be represented by thin discs and that the heat transfer and solidification within the splat propagates in the axial direction only. However, the experiments showed that these assumptions are better suited for the central region of the splat. The occurrence of remelting often depended on the radial location for a given amount of superheat. For most part, the splat exhibited globular microstructure. Lamellar structures were observed near the top and the periphery of the splat, indicating slower cooling rates at these locations. The theoretical model constituted a good compromise between accuracy and simplicity and predicted the correct trends of the remelting phenomenon.

Similar content being viewed by others

Abbreviations

- c :

-

Specific heat (J kg−1 K−1)

- d :

-

Diameter of a spherical droplet (mm)

- D :

-

Diameter of the splat (mm)

- h a :

-

Convective heat-transfer coefficient (W m−2K−1)

- h c :

-

Contact heat-transfer coefficient (Wm−2K−1)

- H :

-

Height of the splat (mm)

- I :

-

Number of nodes in the axial direction in a splat

- k :

-

Thermal conductivity (W m−1 K−1)

- K f :

-

Freezing kinetics coefficient (m s−1K−1)

- L :

-

Latent heat (J kg−1)

- M :

-

Number of nodes in the radial direction in a substrate

- N :

-

Number of nodes in the axial direction in a substrate

- r :

-

Radial coordinate (mm)

- R :

-

Radius of a splat (mm)

- Δr :

-

Increment of radial coordinate (mm)

- t :

-

Time (s)

- t′ :

-

Time lapsed since the solidification of the bottom splat starts

- T :

-

Temperature (°C)

- T f :

-

Equilibrium freezing temperature (°C)

- T 0 :

-

Initial temperature of the top splat (°C)

- T ∞ :

-

Initial temperature of the substrate or ambient air temperature (°C)

- V :

-

Interface velocity (m s−1)

- z :

-

Axial coordinate (mm)

- Δz :

-

Increment of axial coordinate (mm)

- ξ :

-

Spread factor

- ϱ :

-

Density (kg m−3)

- l :

-

Liquid

- m :

-

Index taking on the values s for solid or l for liquid

- s :

-

Solid

- b :

-

Bottom of control volume containing the freezing interface

- i :

-

Interface

- j :

-

Index taking on the values 1 for the first (bottom) splat or 2 for the second (top) splat

- sup :

-

Amount of superheat of the second splat

- t :

-

Top of control volume containing the freezing interface

- 1:

-

First splat

- 2:

-

Second splat

References

H. Jones, “Rapid solidification of metals and alloys”, Monograph 8 (Institution of Metallurgists, London, 1982).

E. Gutierrez-Miravete, PhD thesis, Massachusetts Institute of Technology (1985).

S. Annavarapu, D. Apelian andA. Lawley,Metall. Trans. 21A (1990) 3237.

R. H. Bricknell,ibid. 7A (1986) 583.

R. G. Brooks, C. Moore, A. G. Leatham andJ. S. Coombs,Powder Metall. 2 (1977) 100.

T. R. Anantharaman andC. Suryanarayana,J. Mater. Sci. 6 (1971) 1111.

P. Predecki, A. W. Mullendore andN. G. Grant,Trans. Metall. Soc. AIME 233 (1965) 1581.

W. E. Brower, Jr,R. Strachan andM. C. Flemings,AFS Cast Metals Res. J. 6 (1970) 176.

M. G. Scott,J. Mater. Sci. 9 (1974) 1372.

G.-X. Wang andE. F. Matthys,Int. J. Rapid Solid. 6 (1991) 141.

Idem, Int. J. Heat Mass Transfer 35 (1992) 141.

P. H. Shingu andR. Ozaki,Metall. Trans. 6A (1975) 33.

D. E. Rosnar andM. Epstein,Chem. Eng. Sci. 30 (1975) 511.

P. V. Evans andA. L. Greer,Mater. Sci. Eng. 98 (1988) 357.

T. Bennett andD. Poulikakos,J. Mater. Sci. 29 (1994) 2025.

B. Kang, Z. Zhao andD. Poulikakos,J. Heat Transfer 116 (1994) 436.

J. Madejski,Int. J. Heat Mass Transfer 19 (1976) 1009.

Idem, ibid. 26 (1983) 1095.

C. G. Levi andR. Mehrabian,Metall. Trans. 13A (1982) 221.

T. W. Clyne,ibid. 15B (1984) 369.

S. V. Patankar, “Numerical heat transfer and fluid flow” (Hemisphere, New York 1981).

D. A. Anderson, J. C. Tannehill andR. H. Pletcher, “Computational fluid mechanics and heat transfer” (Hemisphere, New York, 1984).

L. E. Goodrich,Int. J. Heat Mass Transfer 21 (1978) 615.

W. Ranz andW. Marshall,Chem. Eng. Progr. 48 (1952) 141.

ASM Metals Handbook, Vol. 9 “Metallography and microstructures”, 9th Edn (American Society for Metals, Metals Park, OH, 1979).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Kang, B., Waldvogel, J. & Poulikakos, D. Remelting phenomena in the process of splat solidification. J Mater Sci 30, 4912–4925 (1995). https://doi.org/10.1007/BF01154504

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF01154504