Abstract

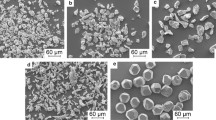

This article is devoted to investigating polycrystalline diamond compacts (PDCs), which find broad application in drilling, tool-and-die, and building branches of industry. They are a complex composition of diamond and cermet phases. The diamond phase consists of diamond grains of various granulometric compositions and shapes and forms a strong hard skeleton. A cermet phase serves as a binder. The presence of catalyst metals in a diamond layer of bilayer PDC composite materials lowers their operational properties, because the difference in thermal expansion coefficients between diamond grains and catalyst can lead to material cracking in the cutting process, while a high temperature when fabricating the diamond tool and its operation in the cutting zone can lead to the reverse diamond–graphite phase transition. In order to increase wear-resistance characteristics of diamond PCD composites formed using catalyst metals (cobalt and tungsten), etching of metals from the surface of the tool working zone is performed by two methods, notably, electrochemical and chemical. Electrochemical etching is performed in sulfuric acid with various current modes and concentration, and chemical etching is performed in a mixture of hydrochloric and nitric acids and a mixture of fluoric and nitric acids. The distribution of the chemical composition over the depth of PCD samples after etching is performed using scanning electron microscopy. It is established that electrochemical etching is more active kinetically, while chemical etching is promising for industrial application. Abrasive tests of PCD samples before and after etching show the absence of a noticeable effect of both electrochemical and chemical etching of their abrasive ability.

Similar content being viewed by others

REFERENCES

Novikov, N.V., Instrumenty iz sverkhtverdykh materialov (Instruments Made of Superhard Materials), Moscow: Mashinostroenie, 2007.

Tetsuo Nakai and Shuji Yazu, US Patent 4636253, 1987.

Elutin, A.V., Laptev, A.I., Manukhin A.V., Sannikov D.S., and Krukova L.M., Synthesis of polycrystalline diamond “Carbonado” from pyrographite, Dokl. Ross. Akad. Nauk, 2001, vol. 378, no. 6, pp. 1–6.

Yihui, Zhao, Wen Yue, Fang Lin, Chengbiao Wang, and Zongyi Wu, Friction and wear behaviors of polycrystalline diamond under vacuum conditions, Int. J. Refract. Met. Hard Mater., 2015, vol. 50, pp. 43–52.

Horton, D.M. and Peterson, G.R., US Patent 4664705, 1987.

Chun Liu and Fubao Zhou, Effect of soaking time on the friction properties of polycrystalline diamonds, Int. J. Refract. Met. Hard Mater., 2015, vol. 48, pp. 82–88.

Westraadt, J.E., Sigalas, I., and Neethling, J.H., Characterisation of thermally degraded polycrystalline diamond, Int. J. Refract. Met. Hard Mater., 2015, vol. 48, pp. 286–292.

Sithebe, H.S. and Ndlovu, A., US Patent 20140352228, 2014.

Ladi, R.L., Wells, C.E., Kataria, B.K., and Almond, S.W., US Patent 20120152064, 2012.

Nojkina, A.V., Laptev, A.I., and Ermolaev, A.A., Influence of synthesis and composition conditions on strength characteristics of synthetic carbonado-type diamonds, High Pressure Res., 2002, vol. 22, pp. 545–549.

Muchnikov, A.B., Vikharev, A.L., Radishev, D.B., Isaev, V.A., and Gorbachev, A.M., A wafer of combined singlecrystalline and polycrystalline CVD diamond, Mater. Lett., 2015, vol. 139, pp. 1–3.

Yahiaoui, M., Gerbaud, L., Paris, Y., Denape, J., and Dourfaye, A., A study on PDC drill bits quality, Wear, 2013, vols. 298–299, pp. 32–41.

Qian, J., McMurray, C.E., Mukhopadhyay, D.K., Wiggins, J.K., Vail, M.A., and Bertagnolli, K.E., Polycrystalline diamond cutters sintered with magnesium carbonate in cubic anvil press, Int. J. Refract. Met. Hard Mater., 2012, vol. 31, pp. 71–75.

Diamond cutters for oil-and-gas industry produced by Element Six. http://www.intech-diamond.com/almaznye-reztsy-dlya-neftyanoj-i-gazovoj-promyshlennosti-kompanii-element-six.html (in Russian, accessed April 15, 2016).

Cutters and billets made of polycrystalline diamonds (PDC, PCD, TSP) LANDS Superabrasives. http://nbt08.ru/common/upload/%D0%9D%D0%91% D0%A2%20%D1%80%D0%B5%D0%B7%D1%86%D1%8B.pdf. (in Russian, accessed April 15, 2016).

Namaraa, D., Alveena, P., Carolana, D., Murphya, N., and Ivankovica, A., Fracture toughness evaluation of polycrystalline diamond as a function of microstructure, Eng. Fract. Mec., 2015, vol. 143, pp. 1–16.

Kanyantaa, V., Dormerb, A., Murphyb, N., and Invankovića, A., Impact fatigue fracture of polycrystalline diamond compact (PDC) cutters and the effect of microstructure, Int. J. Refract. Met. Hard Mater., 2014, vol. 46, pp. 145–151.

Kie, A., Herrmann, M., Sigalas, I., Sempf, K., and Nilen, R., Suppression of abnormal grain growth in fine grained polycrystalline diamond materials (PCD), Int. J. Refract. Met. Hard Mater., 2013, vol. 41, pp. 66–72.

Durfae, A., King, Viliam V., and Ris, Maikl P., US 2 011 118 924, 2010.

Belnap, J.D. and Middlemiss, S.N., US Patent 7 757 791, 2010.

Laptev, A.I., Test methods and mechanical properties of “Carbonado” synthetic polycrystalline diamond, Materialovedenie, 2001, no. 8, pp. 18–21.

ACKNOWLEDGMENTS

This study was performed in the scope of the Federal Target Project of the Program “Researches and Developments on Priority Developmental Directions of the Scientific-and-Technological Complex of Russia for 2014–2020” on the theme “Development of the Fabrication Technology of Highly Efficient Bits of Horizontal and Inclined Drilling for the Oil-and-Gas Branch of Industry” according to agreement no. 14.581.21.0012 (unique agreement identifier RFMEFI58115X0012) and with applied scientific researches supported by the Ministry of Education and Science of the Russian Federation.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Translated by N. Korovin

About this article

Cite this article

Polushin, N.I., Ovchinnikova, M.S. & Sorokin, M.N. Reducing the Metal Content in PCD Polycrystalline Diamond Layer by Chemical and Electrochemical Etching. Russ. J. Non-ferrous Metals 59, 557–562 (2018). https://doi.org/10.3103/S1067821218050139

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1067821218050139