Abstract

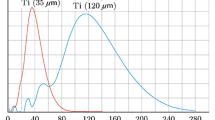

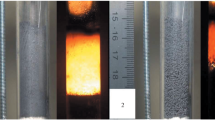

Macrokinetic characteristics of the combustion of mixtures in the (100% − X)(Ti + 0.5C) + X(Ta + C) system with a variable mixing parameter X and initial temperature T 0 of charge heating are considered. For compositions with X = 10 and 30%, an abrupt increase in the velocity U c and temperature T c of combustion as a result of passing two parallel chemical reactions of titanium and tantalum carbide formation is established. The U c (T 0) and T c (T 0) dependencies are linear for the mixture with X = 50%. By hardening the combustion wave, it is revealed that the primary structure formation in the combustion region starts from the selection of submicron grains of nonstoichiometric titanium carbide from the supersaturated titanium melt. In the investigated range of parameter X, synthetic products are single-phase and represent titanium-tantalum carbide. An increase in X results in a decrease in the size and microhardness of (Ti, Ta) C grains and a reduction of the relative density of compact synthetic products. The kinetics of high-temperature oxidation of alloys on the basis of carbide (Ti, Ta) C is studied. Ceramics produced at X = 10% are most heat-resistant.

Similar content being viewed by others

References

Levashov, E.A., Shtansky, D.V., Senatulin, B.R., and Rossi, F., Tsvetn. Met., 2004, no. 2, p. 85.

Shtansky, D.V., Glushankova, N.A., Bashkova, I.A. et al., Biomaterials, 2006, vol. 27, p. 3519.

Shtansky, D.V., Glushankova, N.A., Sheveiko, A.N. et al., Biomaterials, 2005, vol. 26, p. 2909.

Shtansky, D.V., Levashov, E.A., Glushankova, N.A. et al., Fiz. Met. Metalloved., 2004, no. 5, p. 34.

Shtansky, D.V., Levashov, E.A., Glushankova, N.A. et al., Surf. Coat. Technol., 2004, vol. 182, p. 101.

Shtansky, D.V. and Levashov, E.A., Izv. Vyssh. Uchebn. Zaved., Tsvetn. Metall., 2001, no. 3, p. 52.

Shtansky, D.V., Glushankova, N.A., and Bashkova, I.A., Surf. Coat. Technol., 2005, vol. 202, p. 3615.

Levashov, E.A., Rogachev, A.S., Yukhvid, V.I., and Borovinskaya, I.P., Fiziko-khimicheskie i tekhnologicheskie osnovy samorasprostranyayushchegosya vysokotemperaturnogo sinteza (Physicochemical and Technological Foundations of Self-Propagating High-Temperature Synthesis), Moscow: BINOM, 1999.

Shtansky, D.V., Petrzhik, M.I., Bashkova, I.A., and Kiryukhantsev-Korneev, F.V., Fiz. Tverd. Tela, 2006, vol. 48, no. 7, p. 1231 [Phys. Sol. State (Engl. Transl.), 2006, vol. 48, no. 7, p. 1301].

Shtansky, D.V., Bashkova, I.A., Levashov, E.A. et al., Dokl. Ross. Akad. Nauk, 2005, vol. 404, no. 2, p. 1.

Levashov, E.A., Shtansky, D.V., Glushankova, N.A., and Reshetov, I.V., RF Patent 2 281 122, 2005.

Shtansky, D.V., Levashov, E.A., Bashkova, A.I. et al., Tekhnol. Zhivykh Sist., 2005, vol. 2, nos. 4–5, p. 7.

Levashov, E.A., Rogachev, A.S., Epishko, Yu.K., and Kochetov, N.A., Izv. Vyssh. Uchebn. Zaved., Poroshk. Metall. Funkts. Pokrytiya, 2007, no. 1, p. 14.

Mossino, P., Ceram. Int., 2004, vol. 30, no. 3, p. 311.

Kharat’yan, S.L., Samorasprostranyayushchiisya vysokotemperaturnyi sintez: teoriya i praktika (Self-Propagating High-Temperature Synthesis: Theory and Practice), Sychev, A.E., Ed., Chernogolovka: Territoriya, 2001, p. 157.

Rogachev, A.S., Mukas’yan, A.S., and Merzhanov, A.G., Dokl. Akad. Nauk SSSR, 1987, vol. 297, no. 6, p. 1425.

GOST (State Standard) 9450-67 or ASTM Standard E-384-89, Method of Determination of Microhardness of Materials.

Hollek, H., Dvoinye i troinye karbidnye i nitridnye sistemy perekhodnykh metallov: Spravochnik (Binary and Ternary Carbide and Nitride Systems of Transition Metals: Handbook), Moscow: Metallurgiya, 1988.

Merzhanov, A.G. and Mukas’yan, A.S., Tverdoplamennoe gorenie (Solid-Fiery Burning), Moscow: Torus, 2007.

Levashov, E.A., Senatulin, B.R., Leyland, A., and Matthews, A., Izv. Vyssh. Uchebn. Zaved., Tsvetn. Metall., 2006, no. 1, p. 66.

Merzhanov, A.G., Vestn. Akad. Nauk SSSR, 1979, no. 8, p. 10.

Pearson, W., Lattice Spacings and Structures of Metals and Alloys, New York: Pergamon, 1957.

Kiparisov, S.S., Levinskii, Yu.V., and Petrov, V.M., Karbid titana (Titanium Carbide), Moscow: Metallurgiya, 1989.

Storms, E., Tugoplavkie karbidy (Refractory Carbides), Moscow: Atomizdat, 1970.

Voitovich, R.F. and Pugach, E.A., Okislenie tugoplavkikh soedinenii: Spravochnik (Oxidation of Refractory Compounds: Handbook), Moscow: Metallurgiya, 1978.

Kubashevsky, A. and Hopkins, B., Okislenie metallov i splavov (Oxidation of Metals and Alloys), Moscow: Mir, 1969 (in Russian).

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © E.A. Levashov, V.V. Kurbatkina, A.S. Rogachev, N.A. Kochetov, E.I. Patsera, N.V. Sachkova, 2008, published in Izvestiya VUZ. Poroshkovaya Metallurgiya i Funktsional’nye Pokrytiya, 2008, No. 5, pp. 25–35.

About this article

Cite this article

Levashov, E.A., Kurbatkina, V.V., Rogachev, A.S. et al. Characteristic properties of combustion and structure formation in the Ti-Ta-C system. Russ. J. Non-ferrous Metals 49, 404–413 (2008). https://doi.org/10.3103/S1067821208050179

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1067821208050179