Abstract

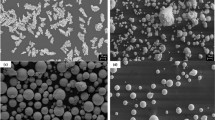

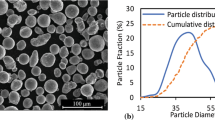

Nanocrystalline Al−Mg coatings were produced using the cold gas dynamic-spraying technique. Unsieved Al−Mg powder of average nanocrystalline grain size in the range of 10 to 30 nm and with a particle size distribution from 10 to >100 μm was used as the feedstock powder. The resulting coatings were evaluated using scanning electron microscopy (SEM), transmission electron microscopy, as well as microhardness and nanoindentation measurements. Coating observations suggest that the wide particle size distribution of the feedstock powder has a detrimental effect on the coating quality but that it can be successfully mitigated by optimizing the spraying parameters. Nanohardness values close to 3.6 GPa were observed in both the feedstock powder and coatings, suggesting the absence of cold-working hardening effects during the process. The effects of the substrate surface roughness and thickness on coating quality were investigated. The deposited mass measurements performed on the coatings showed that the effect of using different grit sizes for the substrate preparation is limited to small changes in the deposition efficiency of only the first few layers of deposited material. The SEM observation showed that the substrate surface roughness has no significant effect on the macrostructures and microstructures of the coating. The ability to use the cold gas dynamic spraying process to produce coatings on thin parts without noticeable substrate damage and with the same quality as coatings produced on thicker substrates was demonstrated in this work.

Similar content being viewed by others

References

A.P. Alkhimov, A.N. Papyrin, V.F. Kosarev, N.I. Nesterovich, and M.M. Shushpanov, Gas-Dynamic Spraying Method for Applying a Coating, U.S. Patent 5,302,414, April 12, 1994

T.H. Van Steenkiste, J.R. Smith, and R.E. Teets, Aluminum Coatings via Kinetic Spray with Relatively Large Powder Particles, Surf. Coat. Technol., 2002, 154, p 237–252

C.-J. Li, W.-Y. Li, and H. Fukanuma, Impact Fusion Phenomenon During Cold Spraying of Zinc, Thermal Spray 2004: Advances in Technology and Application, ASM International, May 10–12, 2004 (Osaka, Japan), ASM International, 2004, p 1129 p

C. Borchers, F. Gärtner, T. Stoltenhoff, and H. Kreye, Microstructural and Macroscopic Properties of Cold Sprayed Copper Coatings, J. Appl. Phys., 2003, 93, p 10064–10070

R. Morgan, P. Fox, J. Pattison, C. Sutcliffe, and W. O'Neill, Analysis of Cold Gas Dynamically Sprayed Aluminum Deposits, Mater. Lett., 2004, 58, p 1317–1320

C.-J. Li and W.-Y. Li, Deposition Characteristics of Titanium Coating in Cold Spraying, Surf. Coat. Technol., 2003, 167, p 278–283

R.S. Lima, J. Karthikeyan, C.M. Kay, J. Lindemann, and C.C. Berndt, Microstructural Characteristics of Cold-Sprayed Nanostructured WC-Co Coatings. Thin Solid Films, 2002, 416, p 129–135

L. Ajdelsztajn, B. Jodoin, G.E. Kim, J.M. Schoenung, and J. Mondoux, Cold Spray Deposition of Nanocrystalline Aluminum Alloys, Metall., Mater. Trans. A, 2005, 36, p 657–666

R.C. Dykhuizen, M.F. Smith, D.L. Gilmore, R.A. Neiser, X. Jiang, and S. Sampath, Impact of High Velocity Cold Spray Particles, J. Thermal Spray Technol., 1999, 8(4), p 559–564

H. Assadi, F. Gärtner, T. Stoltenhoff, and H. Kreye, Bonding Mechanism in Cold Gas Spraying, Acta Mater., 2003, 51, p 4379–4394

A.P. Alkhimov, A.I. Gudilov, V.F. Kosarev, and N.I. Nesterovich, Specific Features of Microparticle Deformation Upon Impact on a Rigid Barrier, J. Appl. Mech. Tech. Phys., 2000, 41(1), p 188–192

M. Grujicic, J.R. Saylor, D.E. Beasley, W.S. DeRosset, and D. Helfritch, Computational Analysis of the Interfacial Bonding Between Feed-Powder Particles and the Substrate in the Cold-Gas Dynamic-Spray Process. Appl. Surf. Sci., 2003, 219, p 211–227

T. Schmidt, F. Gärtner, H. Assadi, and H. Kreye, Development of a Generalized Parameter Window for Cold Spray Deposition, Acta Mater., 2006, 54, p 729–742

P. Richer, B. Jodoin, and L. Ajdelsztajn, ‘Characteristics of Cold Sprayed Coatings Using Nano-Aluminum and Nano-Nickel Powders,’ 16th Canadian Materials Science Conference, Ottawa, ON, Canada, June 2004

E. Sansoucy, B. Jodoin, and L. Ajdelsztajn, Conventional and Nano-Structured Nickel Coatings Produced by Cold Spray Processing, 16th Canadian Materials Science Conference, Ottawa, ON, Canada, June 2004

L. Ajdelsztajn, B. Jodoin, and J.M. Schoenung, Synthesis and Mechanical Properties of Nanocrystalline Ni Coatings Produced by Cold Gas Dynamic Spraying, Surf. Coat. Technol., in press (corrected proof available online February 28, 2006)

L. Ajdelsztajn, A. Zuniga, B. Jodoin, and E. Lavernia, Cold Gas Dynamic Spraying of a High Temperature Al Alloy, Surf. Coat. Technol., in press (corrected proof available online July 19, 2005)

E. Gaffet, N. Malhouroux, and M. Abdellaoui, Far from Equilibirum Phase Transition Induced by Solid State Reaction in the Fe−Si System. J. Alloys Compd., 1993, 194, p 339–360

L. Ajdelsztajn, F. Tang, G.E. Kim, V. Provenzano, and J.M. Schoenung, Synthesis and Oxidation Behavior of Nanocrystalline McrAIY Bond Coatings, J. Thermal Spray Technol., 2005, 14(1), p 23–30

L. Ajdelsztajn, J. Lee, K. Chung, F.L. Bastian, and E.J. Lavernia, Synthesis and Nanoindentation Study of High-Velocity Oxygen Fuel Thermal-Sprayed Nanocrystalline and Near-Nanocrystalline Ni Coatings, Metal. Mater. Trans. A, 2002, 33, p 647–655

T. Stoltenhoff, H. Kreye, H.R. Richter, and H. Assadi, Optimization of the Cold Spray Process, Thermal Spray 2001: New Surfaces for a New Millennium, C.C. Berndt, K.A. Khor, and E.F. Lugscheider, Ed., May 28–30, 2001 (Singapore), ASM International, 2001, 1381 p

T. Stoltenhoff, H. Kreye, and H.J. Richter, An Analysis of the Cold Spray Process and Its Coatings, J. Thermal Spray Technol., 2002, 11(4), p 542–550

J. Vlcek, L. Gimeno, H. Huber, and E. Lugscheider, A Systematic Approach to Material Eligibility for the Cold Spray Process, J. Thermal Spray Technol., 2005, 14(1), p 125–133

J. Vlcek, H. Huber, H. Voggenreiter, A. Fischer, E. Lugscheider, H. Hallen, and G. Pache, Kinetic Powder Compaction Applying the Cold Spray Process: A Study on Parameters, Thermal Spray 2001: New Surfaces for a New Millennium, C.C. Berndt, K.A. Khor, and E.F. Lugscheider, Ed., May 28–30, 2001, (Singapore), ASM International, 2001, 1381 p

F. Zhou, X.Z. Liao, Y.T. Zhu, S. Dallek, and E.J. Lavernia, Microstructural Evolution During Recovery and Recrystallization of a Nanocrystalline Al−Mg Alloy Prepared by Cryogenic Ball Milling, Acta Mater., 2003, 51, p 2777–2791

C. Suryanarayana, Nanocrystalline Materials, Int. Mat. Rev., 1995, 40, p 41–64

B. Jodoin, F. Raletz, and M. Vardelle, Cold Spray Modelling and Validation Using an Optical Diagnostic Method, Surf. Coat. Technol., 2006, 200, p 4424–4432

B. Jodoin, Cold Spray Nozzle Mach Number Limitation, J. Thermal Spray Technol., 2002, 11(4), p 496–507

E. Rabinowicz, An Adhesive Wear Model Based on Variations in Strength Values, Wear, 1980, 63, p 175–181

T.H. Van Steenkiste, Kinetic Spray: A New Coating Process, Key Eng. Mater., 2001, 197, p 59–86

Author information

Authors and Affiliations

Additional information

The original version of this paper was published in the CD ROM Thermal Spray Connects: Explore Its Surfacing Potential, International Thermal Spray Conference, sponsored by DVS, ASM International, and IIW International Institute of Welding, Basel, Switzerland, May 2–4, 2005, DVS-Verlag GmbH, Düsseldorf, Germany.

Rights and permissions

About this article

Cite this article

Richer, P., Jodoin, B. & Ajdelsztajn, L. Substrate roughness and thickness effects on cold spray nanocrystalline Al−Mg coatings. J Therm Spray Tech 15, 246–254 (2006). https://doi.org/10.1361/105996306X108174

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1361/105996306X108174