Abstract

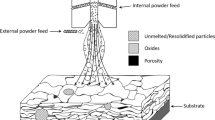

The cold gas-dynamic spray method produces coatings or deposits by introducing solid feedstock particles into a supersonic gas stream developed through the use of a converging-diverging (de Laval) nozzle. The particles thus accelerated impact on a substrate surface and develop into a dense deposit through a process believed to be similar to cold compaction. The work reported here explores the internal nature and physical characteristics of copper deposits produced by the cold gas-dynamic spray method using two vastly different starting powders: in one case, a “spongy” copper obtained by a direct-reduction process, and in the second, a denser, more spheroidal particulate produced by gas atomization. Optical and electron microscopies (scanning electron microscopy [SEM] and transmission electron microscopy [TEM]) were used to observe details of microstructure in the feedstock particles and deposits. Young’s modulus and residual stress measurements for the deposits were obtained through mechanical means, and measurements of hardness and electrical conductivity are reported. The internal structure of the cold-spray deposit was influenced by the surface purity of the feedstock material.

Similar content being viewed by others

References

T.W. Clyne and S.C. Gill: J. Thermal Spray Technol., 1996, vol. 5, pp. 401–18.

Y.A. Kharlamov: Mater. Sci. Eng., 1987, vol. 93, pp. 1–37.

G.H. Smith, R.C. Eschenbach, and J.F. Pelton: U.S. Patent 2,861,900, Nov. 25, 1958.

J.A. Browning: J. Thermal Spray Technol., 1992, vol. 1, pp. 289–92.

C.F. Rocheville: U.S. Patent 3,100,724, Aug. 13, 1963.

A.P. Alkhimov, V.F. Kosarev, and A.N. Papyrin: Sov. Phys. Dokl., 1990, vol. 35, pp. 1047–49.

A.P. Alkhimov, A.N. Papyrin, V.F. Kosarev, N.I. Nesterovich, and M.M. Shushpanov: U.S. Patent 5,302,414, Apr. 12, 1994.

H. Gabel and R. Tapphorn: J. Met., 1997, vol. 49 (8), pp. 31–33.

R.B. Bhagat, M.F. Amateau, A. Papyrin, J.C. Conway, Jr., B. Stutzman, and B. Jones: Thermal Spray: A United Forum for Scientific and Technological Advances, ASM International, Materials Park, OH, 1998, pp. 361–67.

R.C. McCune, A.N. Papyrin, J.N. Hall, W.L. Riggs II, and P.H. Zajchowski: in Advances in Thermal Spray Science and Technology, C.C. Berndt and S. Sampath, eds., ASM International, Materials Park, OH, 1995, pp. 1–5.

R.C. McCune, W.T. Donlon, E.L. Cartwright, A.N. Papyrin, E.F. Rybicki, and J.R. Shadley: in Thermal Spray: Practical Solutions for Engineering Problems, C.C. Berndt, ed., ASM International, Materials Park, OH, 1996, pp. 397–403.

T.H. Vansteenkiste, J.R. Smith, R.E. Teets, J.J. Moleski, D.W. Gorkiewicz, R.P. Tison, D.R. Marantz, K.A. Kowalsky, W.L. Riggs II. P.H. Zajchowski, B. Pilsner, R.C. McCune, and K.J. Barnett: Surf. Coatings Technol., 1999, vol. 111 (1), pp. 62–71.

R.C. Dykhuizen and M.F. Smith: J. Thermal Spray Technol., 1998, vol. 7 (2), pp. 205–12.

D. Raybould: J. Mater. Sci., 1981, vol. 16, pp. 589–98.

D.J. Greving, E.F. Rybicki, and J.R. Shadley: J. Thermal Spray Technol., 1995, vol. 3, pp. 379–88.

E.F. Rybicki, J.R. Shadley, Y. Xiong, and D.J. Greving: J. Thermal Spray Technol., 1995, vol. 4 (4), pp. 377–83.

INCRA Monographs on the Metallurgy of Copper, International Copper Association, Inc., New York, NY, 1992.

G. Montavon, B. Robert, C. Verdy, V. Monin, K.E. Atcholi, and C. Coddet: in Thermal Spray: Practical Solutions for Engineering Problems, C.C. Berndt, ed., ASM International, Materials Park, OH, 1996, pp. 827–32.

R.C. McCune, O.O. Popoola, W.T. Donlon, and E.L. Cartwright: Rapid Prototyping and Manufacturing ’98, Society of Manufacturing Engineers, Dearborn, MI, 1998, pp. 495–520.

D. Ohmannn: Master’s Thesis, University of Wisconsin, Madison, WI, 1998.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

McCune, R.C., Donlon, W.T., Popoola, O.O. et al. Characterization of copper layers produced by cold gas-dynamic spraying. J Therm Spray Tech 9, 73–82 (2000). https://doi.org/10.1361/105996300770350087

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1361/105996300770350087